Novel aliphatic polycarbonate

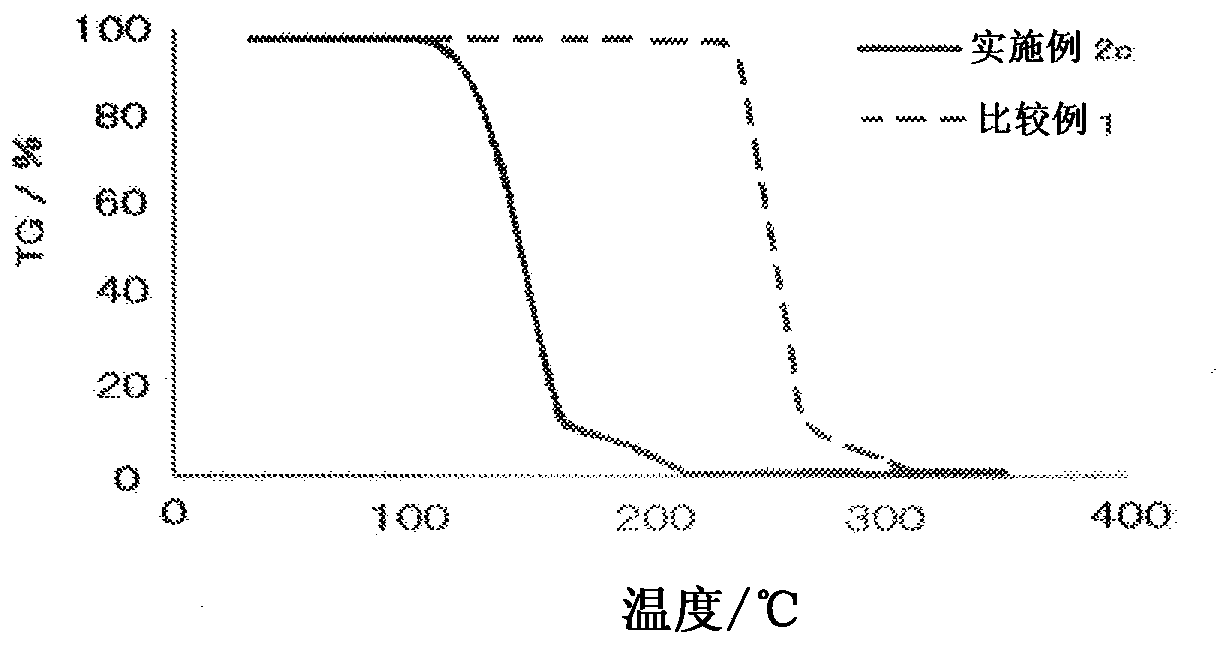

A polycarbonate and aliphatic technology, used in the field of thermal decomposition adhesives, can solve problems such as residual carbon components and adverse effects on product performance, and achieve the effect of reducing thermal energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0160] Hereinafter, although an Example demonstrates this invention concretely, this invention is not limited to these Examples at all. The physical properties and the like of the aliphatic polycarbonate and the like in this example were measured by the following methods.

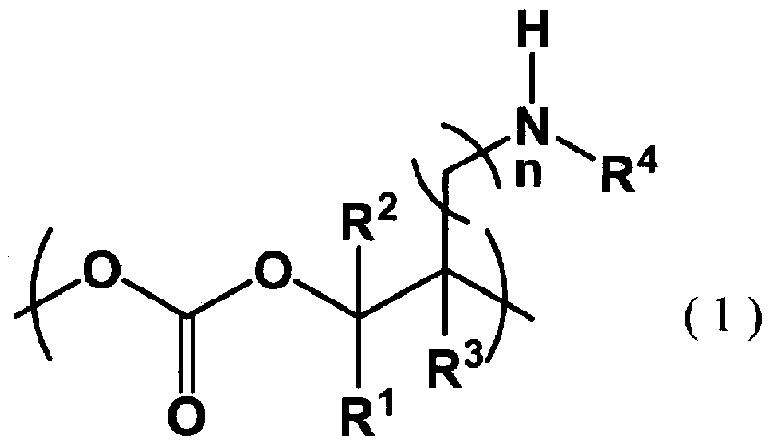

[0161] [Content of Structural Unit Represented by Formula (1) in Aliphatic Polycarbonate]

[0162] pass 1 H-NMR analyzed the composition ratio of the structural unit in resin, and made the content ratio of the secondary amino group in aliphatic polycarbonate into content of the structural unit represented by formula (1).

[0163] Determination of aliphatic polycarbonates in deuterated chloroform at 25°C 1 H-NMR, the integral value (A) of the peak derived from the methine group adjacent to the carbonate group appearing around 5.0 ppm and the integral of the peak derived from the methylene group adjacent to the secondary amino group appearing around 2.4 ppm were obtained Value (B), the amino group content ...

manufacture example 1

[0178] Production Example 1 [Manufacture of Cobalt Complex Catalyst]

[0179] Add N,N'-bis(3,5-di-tert-butylsalicylidene)-1,2-cyclohexanediaminocobalt (Aldrich 0.30 g (8.3 mmol), 0.10 g (8.5 mmol) of pentafluorobenzoic acid, and 13.3 g of dichloromethane were stirred for 19 hours while introducing air. After distilling off the volatile components under reduced pressure, the cobalt complex represented by the above formula (4-3) was obtained as a brown solid (yield: 0.35 g, yield: 88%).

manufacture example 2a

[0180] Production example 2a [production of epoxide containing secondary amino group protected by benzyl group]

[0181]

[0182] Add 865mg (6.3mmol) of potassium carbonate to a 50mL Schlenk tube equipped with a magnetic stirrer, replace the system with an argon atmosphere, and then add 9.4g of N,N-dimethylformamide (DMF) , 0.72 g (5.3 mmol) of N-benzyl-N-ethylamine and 8.5 g (62 mmol) of epibromohydrin. After stirring at normal temperature for 48 hours, extraction was performed three times with 13.3 g of dichloromethane, and the combined organic layer was washed twice with 30 g of saturated brine and once with 30 g of ion-exchanged water. The organic layer was concentrated under reduced pressure, and the obtained residue was purified by silica gel column chromatography (n-hexane / ethyl acetate=4 / 1 (v / v), Rf=0.53) to obtain N- Benzyl-N-oxiranylmethyl-N-ethylamine (yield: 0.93 g, yield: 91%).

[0183] The structure of the resulting compound is obtained by 1 H-NMR for ident...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com