Preparation method and application of two-dimensional bismuthene nanosheet

A technology of nanosheets and bismuth salts, applied in the field of electrochemistry, to achieve the effect of simple synthesis method, abundant raw materials and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1B

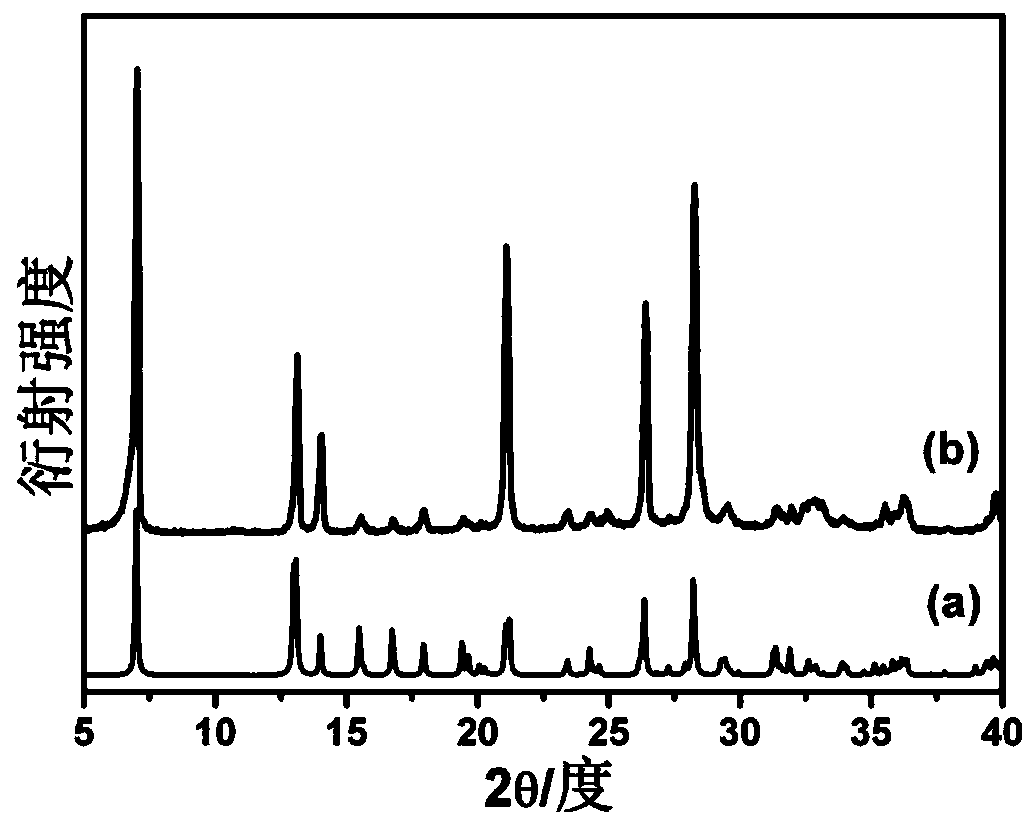

[0044] The preparation of embodiment 1Bi-MOFs-1 precursor

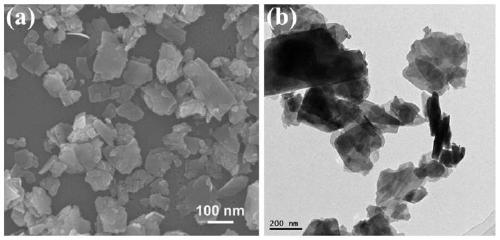

[0045] 1.0 mmol of bismuth nitrate pentahydrate, 2.0 mmol of 4,5-imidazoledicarboxylic acid, and 1.0 mmol of piperazine were added together to 10.0 mL of ultrapure water and stirred for 30 minutes. Then the mixture was transferred to a reaction kettle, and heated to 170° C. for 72 hours. After the reaction, the precipitate at the bottom of the reactor was taken out and washed several times with deionized water, and dried in an oven at 60°C to obtain the Bi-MOFs-1 precursor. Analyze the structure and appearance of the samples. figure 1 (a) is the XRD spectrum of the theoretical Bi-MOFs-1, (b) is the XRD spectrum of the experimentally measured Bi-MOFs-1. The experimentally measured XRD patterns are highly consistent with the theoretical ones, indicating that the prepared Bi-MOFs-1 are phase-pure samples. figure 2 (a) and (b) are the SEM and TEM images of Bi-MOFs-1, respectively, indicating that the prepared Bi-MOFs-...

Embodiment 2

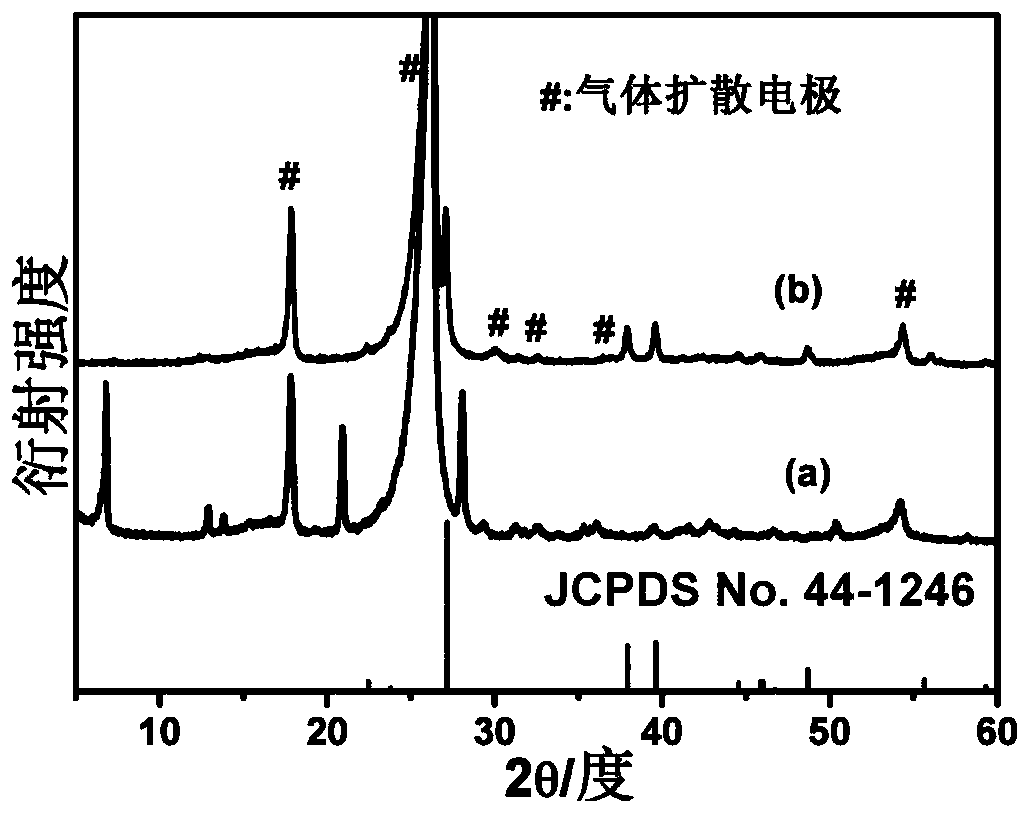

[0046] Example 2 Using Bi-MOFs-1 as a precursor to convert two-dimensional ultrathin bismuthene nanosheets (Bi-ene-1)

[0047] Take 10.0 mg of Bi-MOFs-1 precursor and add 1.0 mL of deionized water / ethanol / Nafion (Nafion is its isopropanol solution, the concentration is 5wt%) to the mixed solution (volume ratio is 7:2:1), Ultrasound for 1 hour to disperse the Bi-MOFs-1 precursor uniformly to obtain a slurry, and then take 0.2mL of the slurry and evenly coat it on a 1.0cm 2 on the carbon paper, so that the loading of Bi-MOFs-1 is 2.0mg cm –2 . After natural drying, the carbon paper coated with Bi-MOFs-1 was used as the working electrode, the saturated Ag / AgCl electrode was used as the reference electrode, the platinum mesh was used as the counter electrode, and 0.5 mol / L potassium bicarbonate saturated with argon The solution is an electrolyte. Then the working electrode was scanned by cyclic voltammetry for 100 cycles in the specified potential window (–1.0–(–1.8V)vs.Ag / AgCl...

Embodiment 3 2

[0048] Example 3 Two-dimensional ultrathin bismuth ene nanosheets (Bi-ene-1) and commercial Bi powder for electrochemical catalysis of CO 2 Restore performance test

[0049] The gas diffusion electrode loaded with Bi-ene-1 obtained in Example 2 was directly used as the working electrode, the saturated Ag / AgCl electrode was used as the reference electrode, and the platinum mesh was used as the counter electrode to test its electrochemical catalytic CO 2 Reduction of the performance of the preparation of formic acid.

[0050] The instruments used are CHI 760E electrochemical workstation and ECZ400S nuclear magnetic resonance instrument. The test device is a proton membrane (perfluorosulfonic acid resin 117) Separated H-type electrochemical reactor, CO 2 The volume of the electrolyte in the reaction chamber is 11.0mL, and the electrolyte is 0.5M KHCO 3 (pH=7.2), normal temperature and pressure, gas flow rate 30.0cc·min –1 , the working electrode area is 1.0cm 2 .

[0051]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com