A Novel Enhanced Composite Phase Change Fluid and Its Preparation Method and Application

A composite phase change and fluid technology, applied in chemical instruments and methods, thermal storage equipment, chemical industry, etc., can solve the problem of large particle size variation of phase change materials, low thermal conductivity of organic phase change materials, and short life of phase change materials and other problems, to achieve good mechanical properties, reduce flammability and liquid fluidity, and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

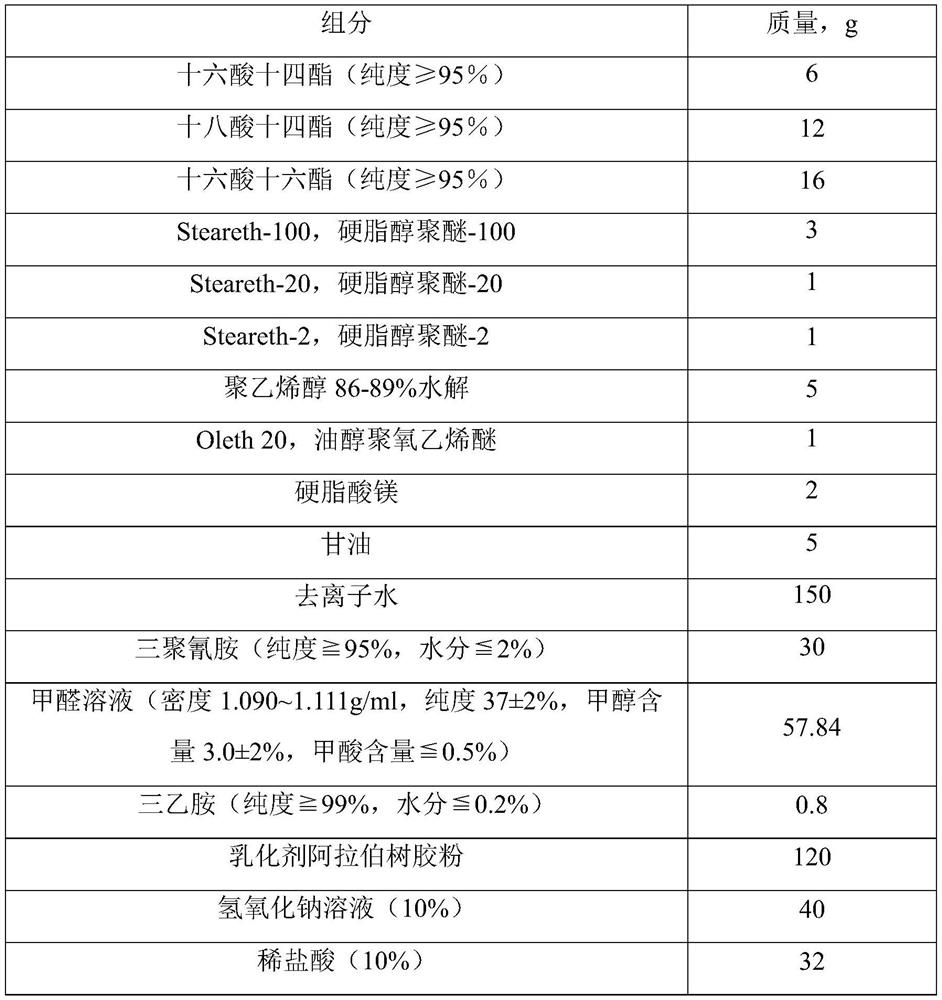

[0049] The preparation of a new type of enhanced composite phase change fluid in this example can be used in direct contact cold storage, and the raw material formula is shown in Table 1.

[0050] Table 1 Embodiment 1 raw material formula

[0051]

[0052] (1) Preheat all the raw materials (deionized water, phase change material, emulsifier and nucleating agent) for preparing the core phase change material to 75°C.

[0053] (2) Mix the preheated phase change materials such as myristyl palmitate and other esters, and stir with a stirrer at a low speed for 15 minutes to prepare the dispersed phase to obtain the first solution; then mix the preheated emulsifier with the synthetic Nucleating agents such as steareth-10, steareth-30, steareth-40, steareth-50, steareth-100, steareth-20 , steareth-2, polyvinyl alcohol, oleyl polyoxyethylene ether, magnesium stearate, glycerin, etc. were added to deionized water, and 0.2 g of nano-sized aluminum nitride and 0.2 g of molybdenum disu...

Embodiment 2

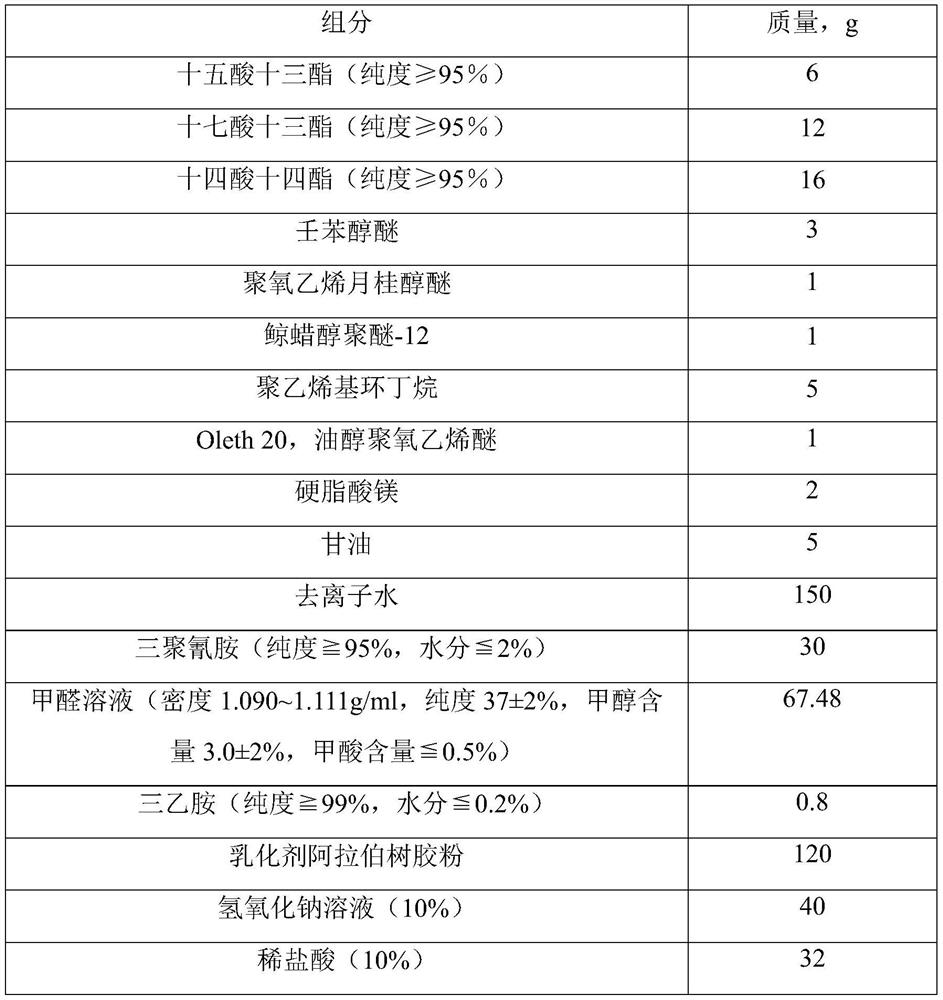

[0060] The preparation of a new type of enhanced composite phase change fluid in this example can be used for solar photovoltaic photothermal panels, and the raw material formula is shown in Table 2.

[0061] Table 2 embodiment 2 raw material formula

[0062]

[0063] (1) Preheat all the raw materials (deionized water, phase change material, emulsifier and nucleating agent, etc.) for preparing the core phase change material to 75°C.

[0064] (2) Mix the preheated phase change materials such as tridecyl pentadecyl esters, and stir with a stirrer at low speed for 15 minutes to prepare the dispersed phase to obtain the first solution; then mix the preheated emulsifier with the synthetic Add nucleating agents such as nonoxynol, polyoxyethylene lauryl ether, ceteth-12, polyvinylcyclobutane, magnesium stearate, and glycerin to deionized water, and add 0.4 g of nano-scale nitrogen aluminum oxide and 0.4 g of molybdenum disulfide. Keep the temperature and keep stirring until the ...

Embodiment 3

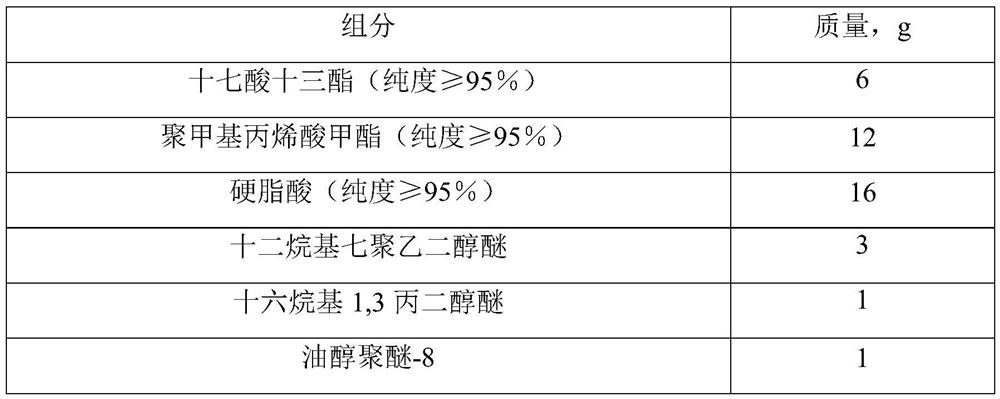

[0071] The preparation of a new type of enhanced composite phase change fluid in this example can be used in the circulating cooling system of the diverter valve, and the raw material formula is shown in Table 3.

[0072] Table 3 embodiment 3 raw material formula

[0073]

[0074]

[0075] (1) Preheat all the raw materials (deionized water, phase change material, emulsifier and nucleating agent, etc.) for preparing the core phase change material to 75°C.

[0076] (2) Mix the preheated phase change materials such as tridecyl heptadecanoate and other ester acids, and stir with a stirrer at a low speed for 15 minutes to prepare the dispersed phase to obtain the first solution; then mix the preheated emulsifier With nucleating agents such as lauryl heptaglycol ether, cetyl 1,3 propylene glycol ether, oleth-8, polyvinyl-2-methylcyclohexane, poly-3-methyl - 1-butene, polycyclopentene and glycerol were added to deionized water, and 1 g of nano-scale aluminum nitride and 1 g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com