Compound curdlan paste preparation and preparation method thereof

A polysaccharide and Deran technology, which is applied in the field of compounding Kederan polysaccharide paste preparation and its preparation, can solve the problems of poor water-holding performance of gel, large storage and use safety risks, loss of natural gum yield and the like, and achieves Good prospects for commercial production and application promotion, avoiding the phenomenon of micro-particles sinking to the bottom, and improving the effect of water-holding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

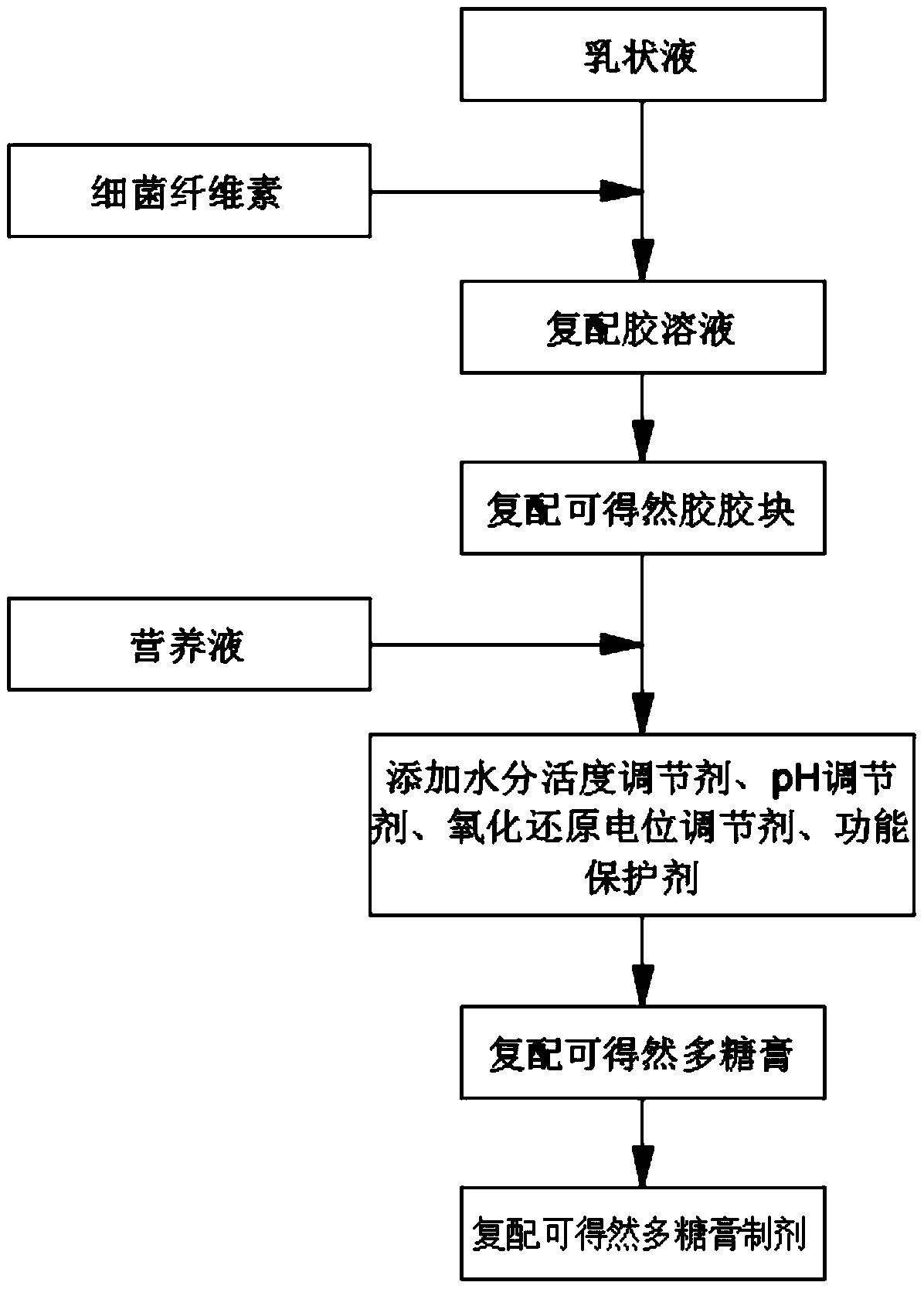

[0091] Such as figure 1 As shown, vitamin B and vitamin C are dissolved in water, and vitamin A and vitamin D are dissolved in peanut oil to obtain a nutrient solution.

[0092] 15% by weight of whey protein and curdlan gum block solution are compounded according to the proportion, and the emulsion is obtained after ultrasonic homogenization.

[0093] Add bacterial cellulose with a weight percentage of 3.5% into the emulsion, fully mix with high-speed stirring at 30°C, and obtain a compound glue solution after constant volume.

[0094] The obtained compounded gum solution is induced by adding acetic acid, pH is adjusted, washed with water and pressure-filtered to obtain a compounded curdlan gum block with a network structure.

[0095] According to weight percentage, quantitatively weigh 20% vegetable oil, 2.5% nutrient solution, 1.4% pH regulator, 17% water activity regulator, 3.1% redox potential regulator, 1.3% functional protection agent and 0.05% food preservative Add t...

Embodiment 2

[0098] Example 2 is the same as Example 1 except that the content of bacterial cellulose in the compound glue solution is different, and the rest of the content is the same, aiming to study the influence of different bacterial cellulose content on the gel strength of the compound curdran polysaccharide paste preparation, the results As shown in Table 8.

[0099] The impact of different bacterial cellulose (BC-f) contents on the gel strength in the preflush of table 8

[0100] BC-f content (wt%) Gel strength (g / cm 2 )

1 596 2 604 3 621 4 635 5 625

[0101] The data in Table 8 shows that with the increase of the bacterial cellulose content in the compound gel solution, the strength of curdlan gum increases, and when the bacterial cellulose weight percentage is 4%, the gel strength reaches the maximum, but the bacterial cellulose Continuing to increase the content will reduce the gel strength. This is because when the bacterial cellu...

Embodiment 3

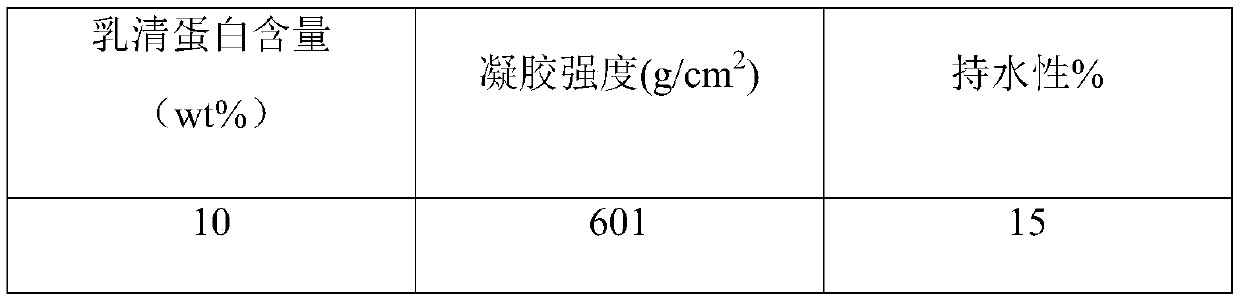

[0104] Example 3 is the same as Example 1 except that the content of whey protein in the compound gel solution is different, and the rest of the content is the same, aiming to study the effect of different whey protein content on the gel strength and water holding capacity of the compound Curdran polysaccharide paste preparation The results are shown in Table 9.

[0105] Table 9 Effects of different whey protein contents on gel strength and water holding capacity

[0106]

[0107]

[0108] The data in Table 9 shows that when the whey protein content in the compound gum solution gradually increases in the range of 10-20wt%, the strength and water holding capacity of curdlan gum will increase accordingly, but when the whey protein content increases When it reaches 25%, the gel strength of curdlan gum decreases instead. This is because when the whey protein content reaches 25wt%, excessive whey protein will destroy the network structure formed between the molecules of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com