Multi-element carbon nitride-based non-metallic material, and preparation method and application thereof

A non-metallic material, carbon nitride-based technology, used in chemical instruments and methods, chemical/physical processes, special compound water treatment, etc., can solve problems such as insufficient visible light absorption, high carrier recombination rate, and low conductivity. , to achieve the effect of excellent activity, rich source of elements, and efficient degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

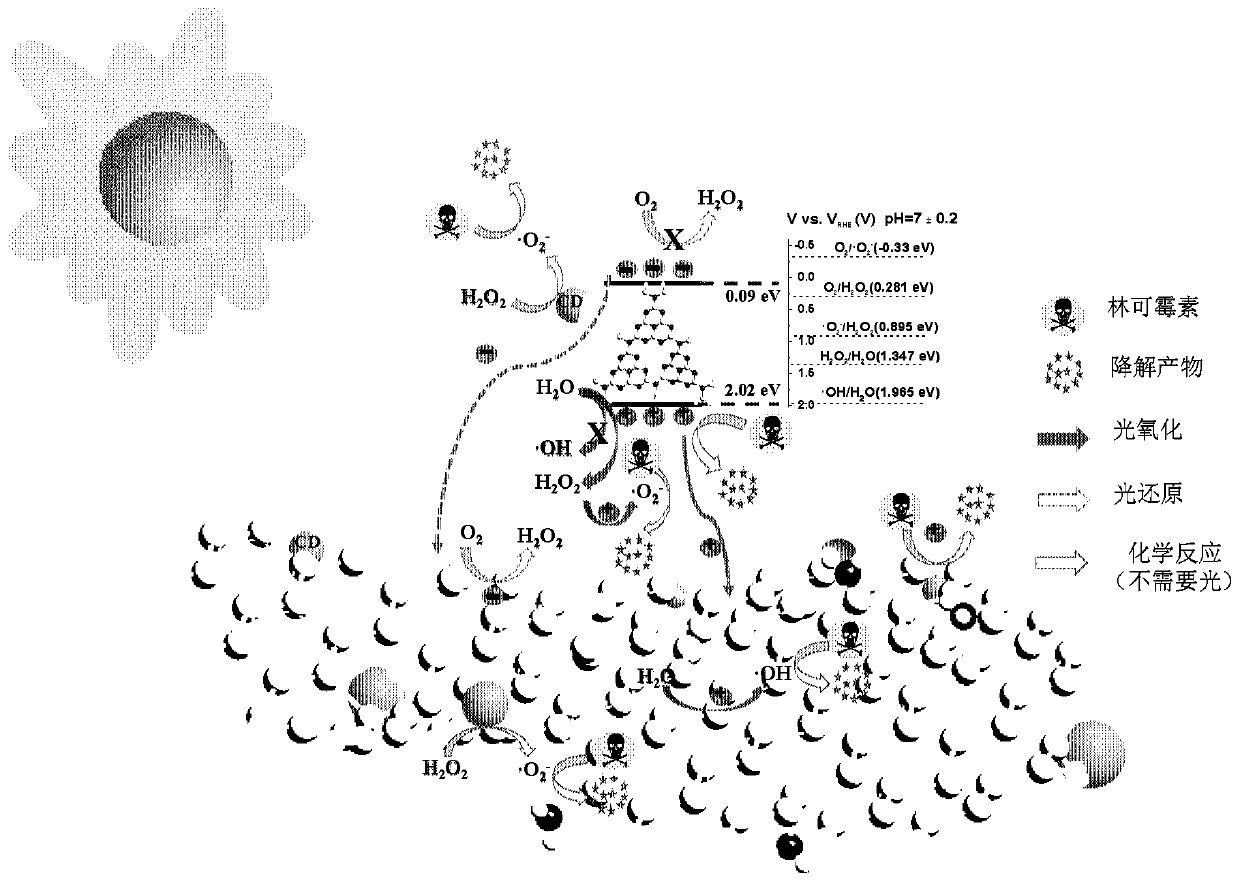

[0026] As one aspect of the present invention, a kind of preparation method of multi-component carbon nitride-based non-metallic material is provided, comprising the steps of:

[0027] Step 1: dissolving graphene oxide in aqueous urea solution, adding a reducing agent for reduction reaction, to obtain a precursor containing urea and reduced graphene oxide;

[0028] In an embodiment of the present invention, in step 1, the mass ratio of urea, graphene oxide and reducing agent added is 10000:(0.2-2):(1-10).

[0029] Wherein, it is worth mentioning that when the mass of urea is 10g, the volume of the aqueous solution is 100ml. However, the concentration is not specifically limited, as long as the mass ratio of urea, graphene oxide and reducing agent added meets the above range.

[0030] In an embodiment of the present invention, in step 1, the reducing agent is sodium borohydride. In the embodiment of the present invention, the reducing agent is not specifically limited, and ma...

Embodiment 1

[0044] Precursor preparation:

[0045] Dissolve 10 g of urea in 100 mL of deionized water, and then add 0.5 mg of graphene oxide. The above mixture was continuously stirred in a water bath until the temperature reached 80 °C, then 0.5 mL of 10 mg / mL sodium borohydride solution was added rapidly, and the mixture was kept stirring at a constant temperature of 80 °C for 3 h. The above mixture was dried in an oven at 80°C for 24 hours, taken out and cooled naturally for later use.

[0046] Catalyst CD-rGO-O-g / C 3 N 4 Preparation of:

[0047] Mix 10g of the above precursor, 1g of oxalic acid, and 3mg of carbon quantum dots evenly, place them in a covered crucible, heat them in a muffle furnace at 5°C / min to 550°C, and keep calcination at 550°C for 3h, and complete the sample after natural cooling Prepare, obtain the CD-rGO-O-g / C that embodiment 1 prepares 3 N 4 .

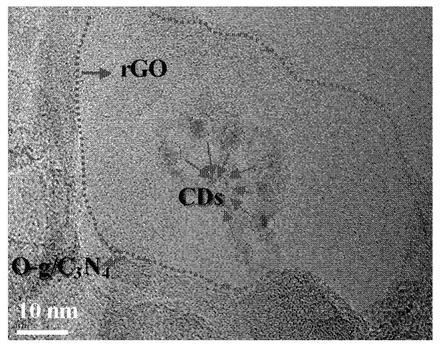

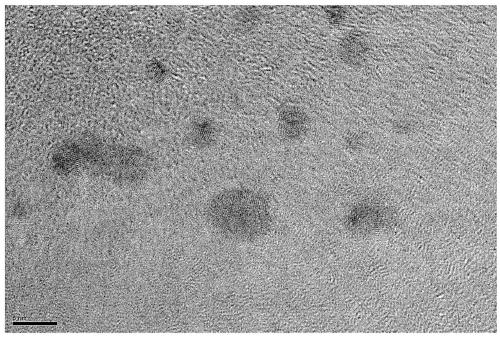

[0048] Characterization:

[0049] The CD-rGO-O-g / C prepared in embodiment 1 was prepared by field emission sca...

Embodiment 2-4

[0055] This example 2-4 uses the preparation method in Example 1 to prepare CD-rGO-O-g / C 3 N 4 , the difference is only in the addition ratio of GO in the precursor.

[0056] Precursor preparation:

[0057] Dissolve 10 g of urea in 100 mL of deionized water, and then add 0.35 mg, 1 mg, and 2 mg of graphene oxide, respectively, to complete the control of the GO ratio. The above three mixtures were continuously stirred in a water bath until the temperature reached 80 °C, and then 0.5 mL of sodium borohydride solution with a concentration of 10 mg / mL was added rapidly respectively, and kept stirring at a constant temperature of 80 °C for 3 h. The above three mixtures were dried in an oven at 80°C for 24 hours, taken out and cooled naturally for later use.

[0058] Mix 10 g of the above three precursors with 1 g of oxalic acid and 3 mg of carbon quantum dots, place them in a covered crucible, heat them in a muffle furnace at 5 °C / min to 550 °C, and keep calcination at 550 °C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com