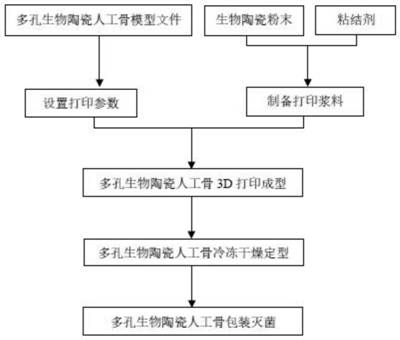

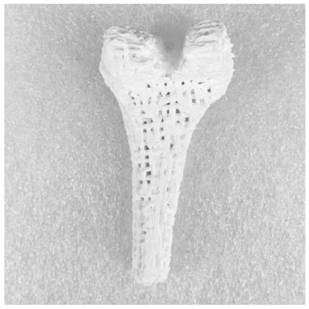

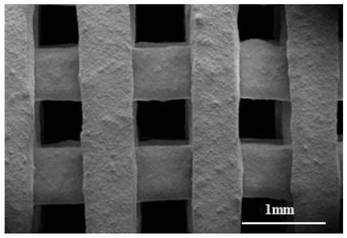

A 3D printing bionic porous bioceramic artificial bone and its preparation method

A bioceramic and artificial bone technology, applied in the field of bone repair materials, can solve the problems of difficulty in realizing microporous bionic requirements, lack, difficult quantitative and precise regulation, etc., achieve good biocompatibility and biodegradability, and improve cell growth. and, the effect of good molding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] S1, preparation of PVA (polyvinyl alcohol) aqueous solution: take 4 g of polyvinyl alcohol powder, dissolve it in 46 g of water for injection, stir with a magnetic stirrer at a constant temperature of 95° C. for 1.5 h, and prepare an aqueous solution of polyvinyl alcohol with a mass fraction of 8%; The centrifuge centrifuges the solution twice at a speed of 3000rad / min, 5min / time, to remove impurities and obtain a uniform and transparent solution;

[0067] S2, preparation of bioceramic powder: Weigh 33.57g of hydroxyapatite powder and 22.38g of β-tricalcium phosphate powder, and mix the two evenly to obtain a uniform bioceramic powder; that is, hydroxyapatite and β-phosphoric acid The mass ratio of tricalcium is 3:2;

[0068] S3, according to the mass fraction, put 52.8% of the bioceramic powder obtained from S2 and the polyvinyl alcohol solution obtained from 47.2% of S1 into a homogenizer, first mix at 800 rad / min for 1 min, and then stir at 2000 rad / min for 4 Mix we...

Embodiment 2

[0080] S1, take 4g of polyvinyl alcohol powder, dissolve it in 46g of water for injection, stir it with a magnetic stirrer at a constant temperature of 95°C for 1.5h, prepare an aqueous solution of polyvinyl alcohol with a mass fraction of 8%, and centrifuge the solution twice with a centrifuge at 3000rad / min, 5min / time, to remove impurities and obtain a uniform and transparent solution;

[0081] S2, weighing 30 g of calcium silicate powder and 30 g of β-tricalcium phosphate powder, and mixing the two evenly to obtain a uniform bioceramic powder, that is, the mass ratio of calcium silicate to β-tricalcium phosphate is 1:1;

[0082] S3, according to the mass fraction, put 52.8% of the bioceramic powder obtained in S2 and 47.2% of the polyvinyl alcohol solution obtained in S1 into a homogenizer, first 800rad / min, premix for 1min, and then turn at 2000rad / min, Stir at high speed for 4 times to mix, each time for 1 minute, put the mixed slurry into the dispensing syringe, and use ...

Embodiment 3

[0093] S1, preparation of polyvinyl alcohol aqueous solution: dissolve polyvinyl alcohol powder in water for injection, prepare a polyvinyl alcohol aqueous solution with a mass fraction of 8%, stir at a constant temperature of 95°C for 1.5h on a magnetic stirrer, and then use a centrifuge at 3000rad / Centrifuge twice at 1 min speed, 5 min each time, to remove impurities and form a uniform transparent solution;

[0094] S2, in terms of mass fraction, put 52.8% of the bioceramic powder and 47.2% of the polyvinyl alcohol solution obtained in S1 into a homogenizer, pre-mix for 1 min at a speed of 800 rad / min, and then mix it with a speed of 2000 rad / min Rotate speed, stir 4 times to mix, each time stir for 1min, put the mixed slurry into the dispensing syringe, use the degassing machine to degas 6 times, get a uniform printable slurry, the silicic acid in the bioceramic powder Calcium: β-tricalcium phosphate mass ratio is 1:1;

[0095] S3, using the method of TPMS combined with C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com