Polymer microsphes with phenylboronic acid groups loaded on surface as well as preparation method and application thereof

A technology of polymer and phenylboronic acid, used in the preparation of microspheres, microcapsule preparations, alkali metal compounds, etc., can solve the problems of complicated preparation methods and uneven dispersion of microspheres, and achieve the effect of good monodispersity and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

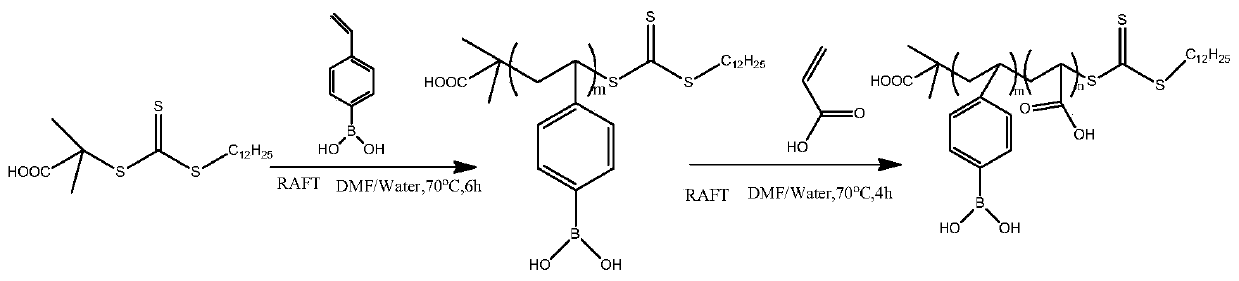

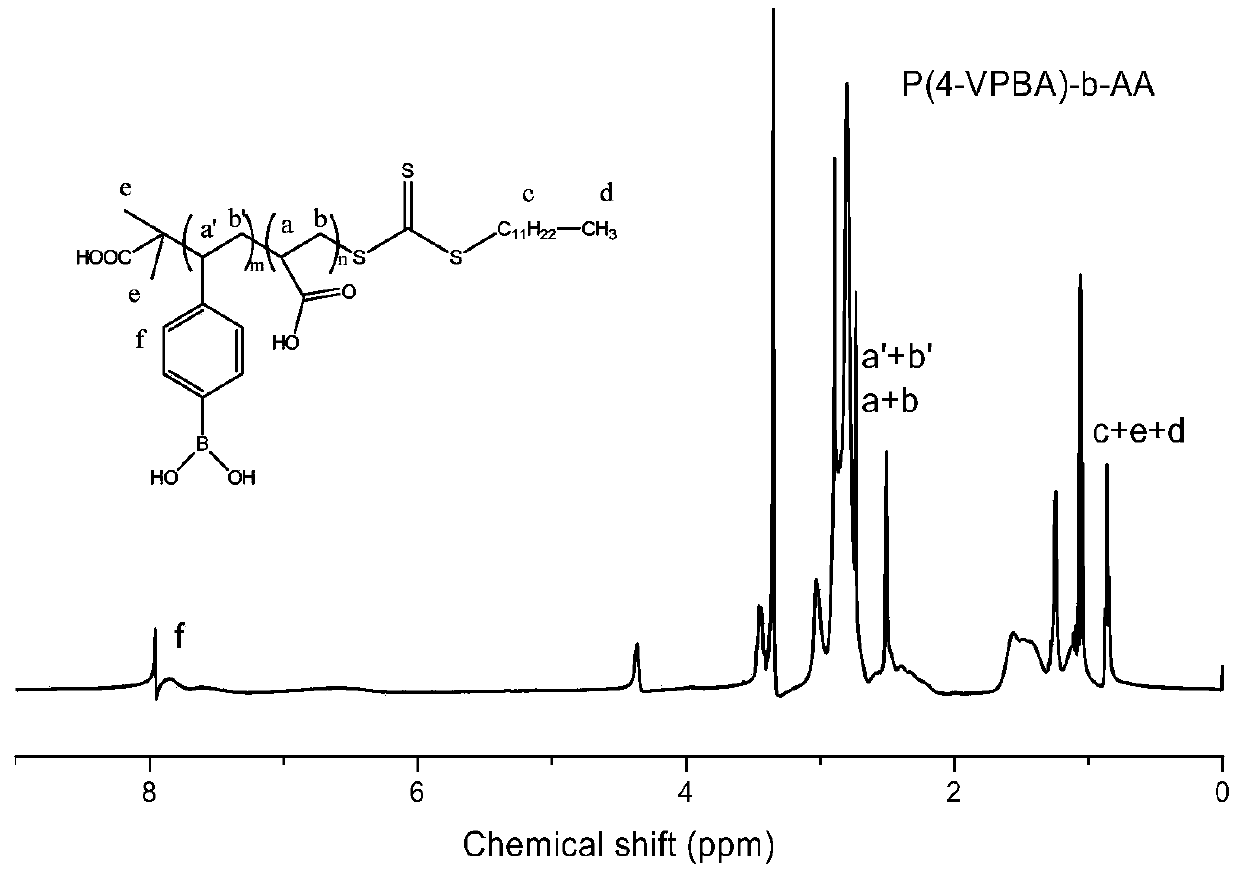

[0036] Embodiment 1 molecule RAFT reagent P (4-VPBA) m -b-AA n Synthesis

[0037] 1. Synthesis of homopolymer P(4-VPBA) 53 -TTC

[0038] 4-vinylphenylboronic acid (4-VPBA) (7.4g, 50mmol), S-1-dodecyl-S'-(α,α'-dimethyl-α"-acetic acid) trithiocarbonic acid Ester (DDMAT) (0.183g, 0.5mmol) and azobisisobutyronitrile (AIBN) (0.083g, 0.05mmol), added to a 25ml flask, dissolved in 20mL N,N-dimethylformamide and A mixed solvent of water (95 / 5v / v), the solution was degassed with nitrogen for 30 minutes, then soaked in a preheated oil bath at 70 degrees Celsius for 6 hours, cooled, exposed to air, precipitated with anhydrous ether, and placed in a vacuum After drying at room temperature, light yellow P(4-VPBA) polymer powder P(4-VPBA) was obtained 53 -TTC.

[0039] 2. Synthesis of block polymers

[0040] P(4-VPBA) 53 - TTC (1.55g, 0.20mmol), acrylic acid (AA) (2.93g, 40.70mmol) and azobisisobutyronitrile (AIBN) (6.56mg, 0.04mmol), added to a 25ml flask, dissolved in 15g In etha...

Embodiment 2

[0041] The preparation of the polymer microsphere that embodiment 2 surface contains phenylboronic acid group

[0042] 1. Take P(4-VPBA) 53 -b-AA 142 -TTC is the synthesis of polymethyl methacrylate (PMMA) microspheres of stable dispersant: in ethanol / water (50 / 50, w / w) system, carry out:

[0043] A 40 / 60 (7.2g+10.8g) ethanol / water mixture by weight ratio was introduced into a 25mL round bottom flask as a solvent, and then 2.0g of methyl methacrylate (MMA) monomer (10wt% relative to the system) was added , 0.30g of stable dispersant P(4-VPBA) 53 -b-AA 142 - TTC (15% relative to monomer), 0.005 g of DDMAT (0.25% relative to monomer) and 0.06 g of photoinitiator Darocur 1173 (3% relative to monomer), magnetically stirred to dissolve. The reaction mixture was deoxygenated with nitrogen for 30 minutes, sealed with a glass stopper with a quartz glass sheet, and then illuminated with a 365nm wavelength LED lamp (light intensity 2.5mW / cm2) under constant stirring. 2 ) was irradi...

Embodiment 3

[0047] The preparation of the polymer microsphere that embodiment 3 surface contains phenylboronic acid group

[0048] 1. Take P(4-VPBA) 53 -b-AA 142 -TTC is the synthesis of polymethylacrylate (PMA) microspheres of stable dispersant: in ethanol / water (50 / 50, w / w) system, carry out:

[0049] The ethanol / water mixture of weight ratio 40 / 60 (7.6g+11.4g) is introduced in the round bottom flask of 25mL as solvent, then add 1.0g methyl acrylate (MA) monomer (5wt% with respect to system), 0.10 g of stabilized dispersant P(4-VPBA) 53 -b-AA 142 - TTC (10% relative to monomer), 0.0025 g of DDMAT (0.25% relative to monomer) and 0.01 g of photoinitiator Darocur 1173 (1% relative to monomer), magnetically stirred to dissolve. The reaction mixture was deoxygenated with nitrogen for 30 minutes, sealed with a glass stopper with a quartz glass sheet, and then illuminated with a 365nm wavelength LED lamp (light intensity 2.5mW / cm2) under constant stirring. 2 ) was irradiated from the top ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com