Biological photovoltaic cell and preparation method thereof

A photovoltaic cell and biological technology, applied in the field of bio-photovoltaic cells and their preparation, can solve problems such as low photoelectric conversion efficiency, and achieve the effects of improving photoelectric conversion efficiency, energy density and photoelectric response performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

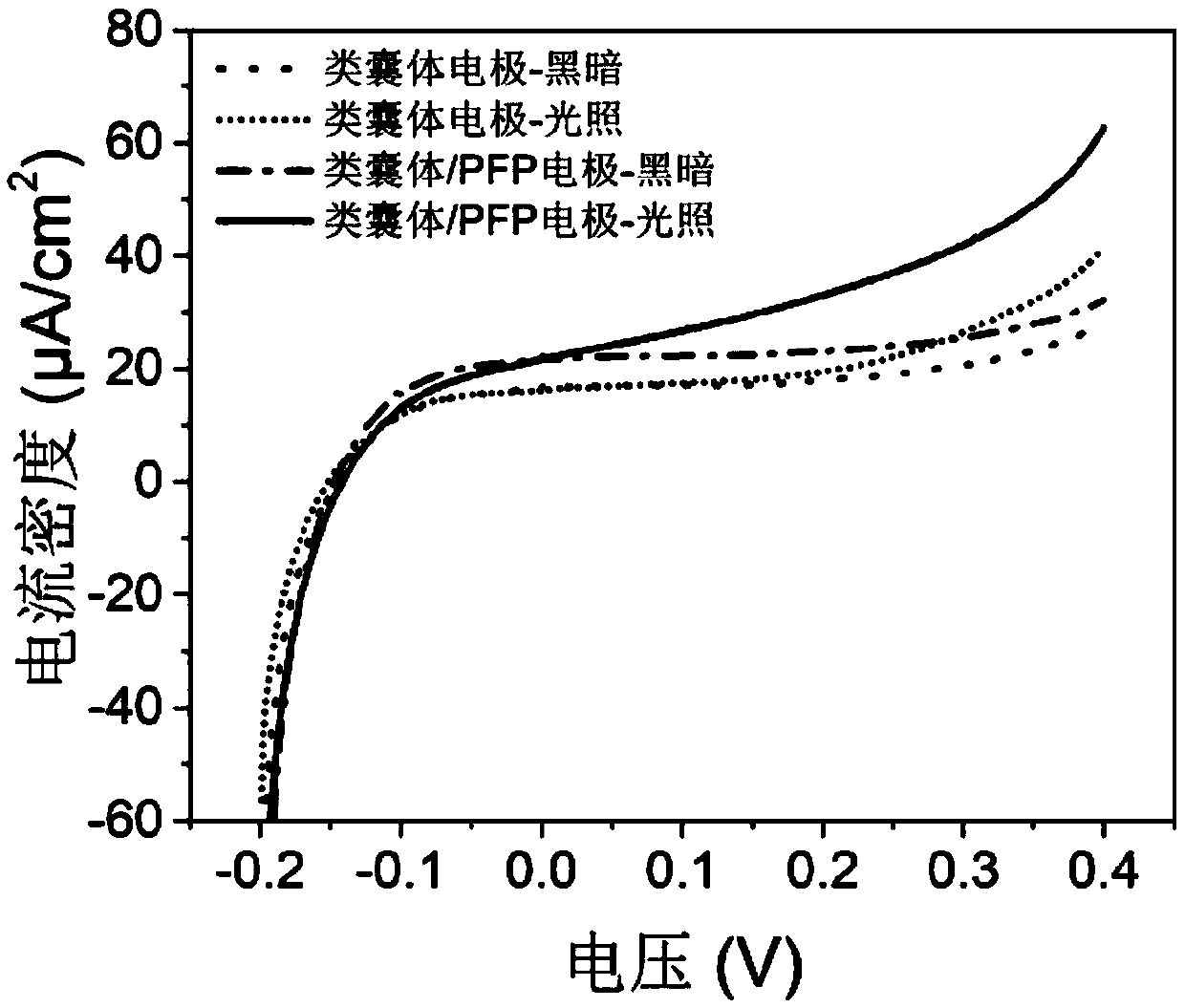

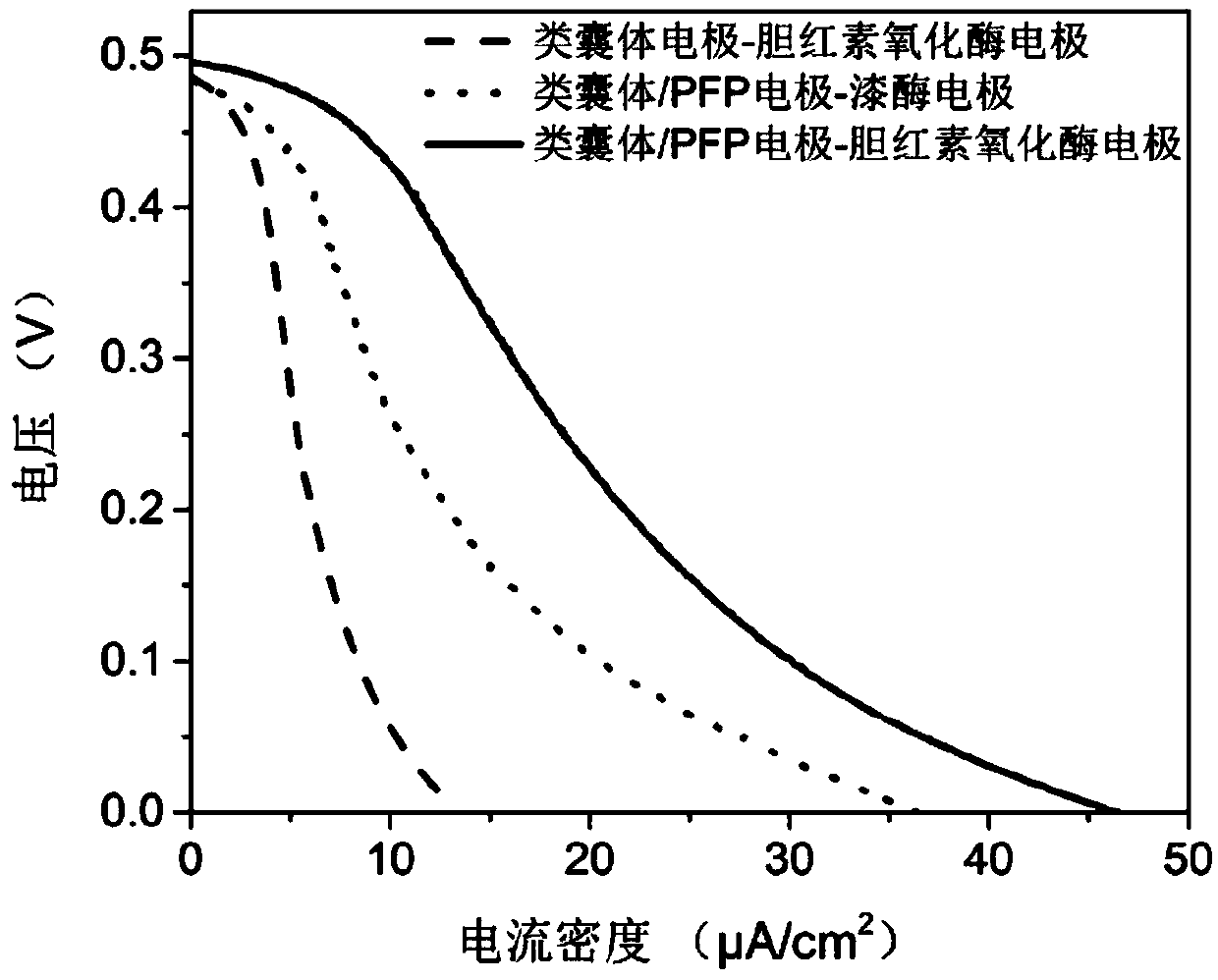

[0026] According to a specific embodiment of the present invention, the anode includes a base material, and a polymer layer and a thylakoid layer sequentially covered on the base material.

[0027] In the anode of the biophotovoltaic cell of the present invention, there is no particular limitation on the amount of PFP and thylakoid, as long as the working electrode can be prepared. In order to further increase the current density of bio-photovoltaic cells, preferably, relative to 0.25cm 2 The substrate material, the molar weight of PFP is 5×10 -4 -2×10 -3 μmol, the mass of thylakoid is 1-2μg.

[0028] The base material may be a base material commonly used in the anode in the art, preferably, the base material is a carbon material, such as carbon paper, carbon cloth, carbon brush, carbon felt, carbon nanotube, and the like. More preferably, the base material is carbon paper.

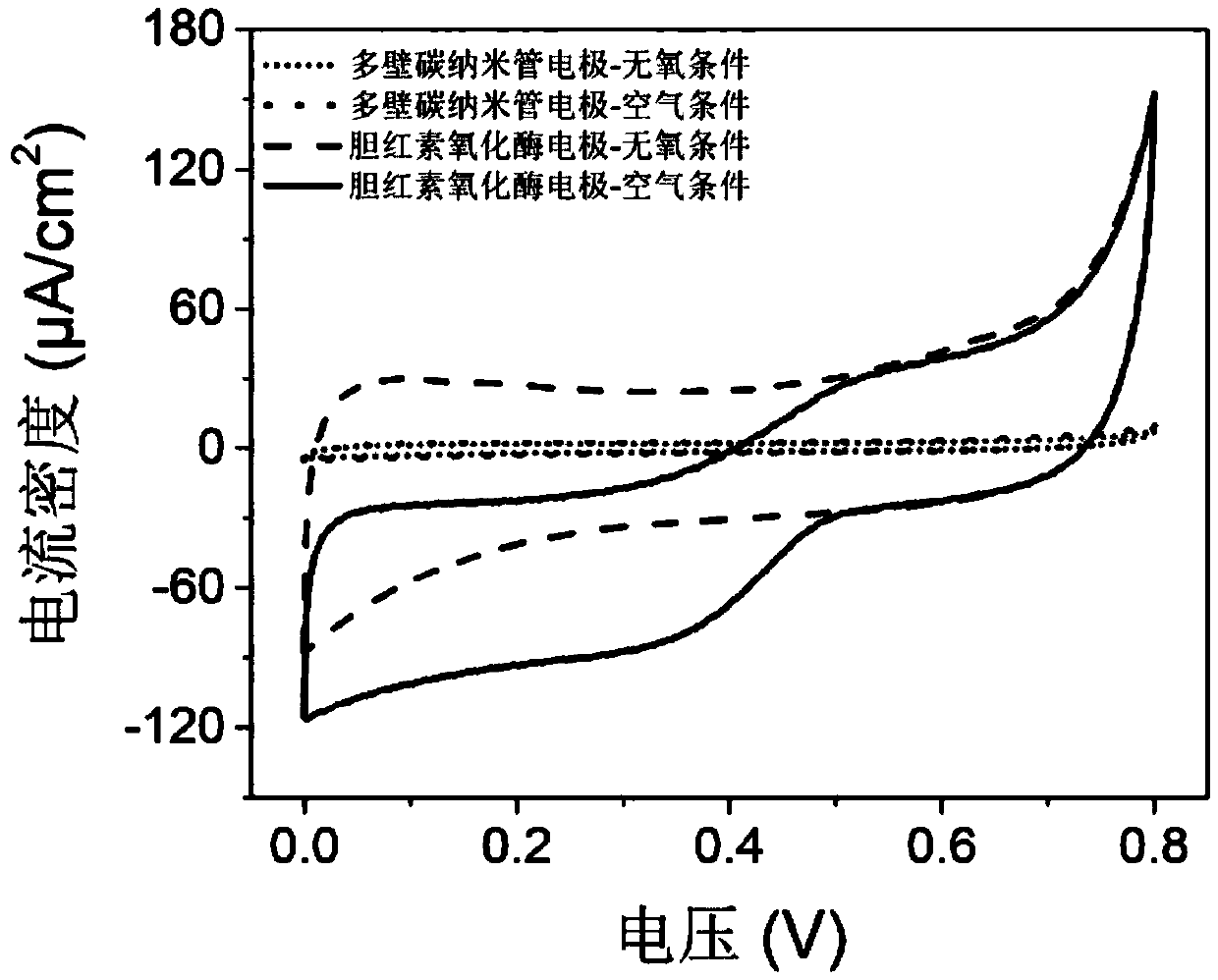

[0029] According to the bio-photovoltaic cell of the present invention, its cathode includes a bas...

preparation example 1

[0076] (1) Preparation of 9,9-bis(6'-bromohexyl)-2,7-dibromofluorene

[0077] 1,6-dibromohexane (97.6g, 400mmol) was added in 100ml of 50% potassium hydroxide solution, 1.28g of phase transfer catalyst tetrabutylammonium bromide (TBAB) was added, and the temperature of the reaction solution was raised to 75°C , then added 2,7-dibromofluorene (12.96 g, 40 mmol) and stirred for 15 min. After the reaction was stopped and cooled to room temperature, extracted with dichloromethane (100ml×3 times), the organic phases were combined, washed with 1M hydrochloric acid solution and distilled water, dried over anhydrous magnesium sulfate, filtered, and concentrated. The crude product was separated and purified by silica gel column chromatography, and the developing solvent was dichloromethane / petroleum ether (v / v=1 / 9) to obtain product V as a white solid (mass 21.4 g, yield 82%).

[0078] The hydrogen spectrum data of V is: 1 H-NMR: (300MHz, CDCl 3 ,ppm)δ:0.58(m,4H),1.08(m,4H),1.21(m,4...

preparation example 2

[0092] Preparation of Thylakoid Suspensions

[0093] Weigh 30g spinach and wash it, quickly remove the veins and cut the leaves into 1-3cm 2 sized fragments were triturated in 60 mL of chloroplast isolation buffer until no fragments remained. Filter the grinding solution with three layers of gauze, collect the filtrate and centrifuge for 3 minutes under the condition of 4° C. and 200 g in a horizontal rotor centrifuge. The supernatant was again centrifuged at 1000g for 7 minutes, and the supernatant was carefully discarded to obtain the first precipitate, which was chlorophyll. Disperse the first precipitate into the hypotonic buffer solution, centrifuge for 10 minutes at 4°C and 4000g in a horizontal rotor centrifuge, discard the supernatant carefully to obtain the second precipitate, and carry out the second precipitate in the homogenization buffer solution twice. After washing for the first time, the third precipitate was obtained, which was resuspended in storage buffer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com