Preparation method of biomass adsorption material for treating heavy metals in domestic sewage

A technology for biomass adsorption and domestic sewage, which is applied in the field of preparation of biomass adsorption materials, can solve the problems of low selectivity, restriction, and poor removal effect of heavy metals, and achieve the effect of good adsorption effect and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

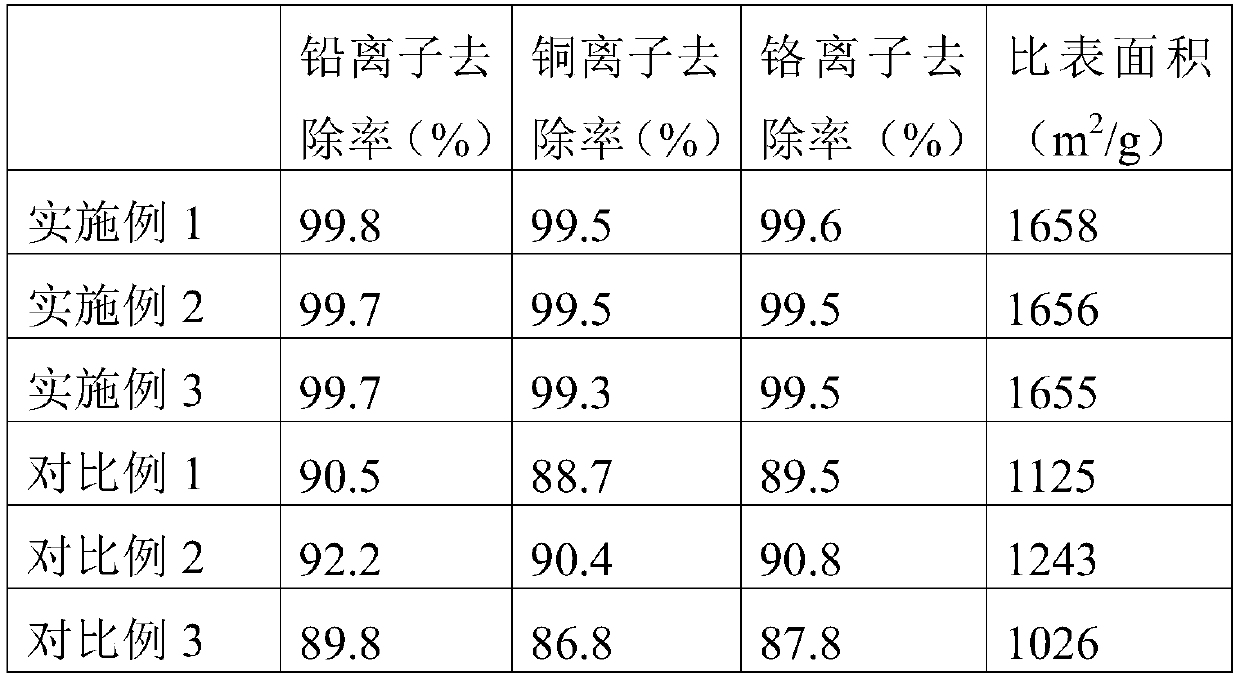

Examples

Embodiment 1

[0024] A preparation method for a biomass adsorption material for heavy metal treatment in domestic sewage, comprising the following steps:

[0025] Step 1. Treat 100g of rice husk in low-temperature corona irradiation equipment for 15min, then add 10g of ammonium carbonate and 10g of melamine in a mixed solution for ultrasonic soaking for 30min, and then filter to obtain pretreated rice husk; The atmosphere treated in the irradiation equipment is air, the temperature is 35°C, the voltage is 10KV, and the distance is 3cm; the power of ultrasonic soaking is 350W, and the ultrasonic frequency is 30kHz; the concentration of the mixed solution is 20g / L; Treating the rice husk to increase the content of active polar functional groups on the surface of the rice husk, deepen the grooves on the surface of the rice husk, increase the specific surface area, and further improve its heavy metal adsorption performance;

[0026] Step 2, using a twin-screw extrusion extruder to extrude and e...

Embodiment 2

[0031] A preparation method for a biomass adsorption material for heavy metal treatment in domestic sewage, comprising the following steps:

[0032] Step 1: Treat 100g of rice husk in a low-temperature corona irradiation device for 10min, then add 10g of ammonium carbonate and 10g of melamine and ultrasonically soak in a mixed solution for 25min, then filter to obtain pretreated rice husk; The atmosphere treated in the equipment is air, the temperature is 30°C, the voltage is 15KV, and the distance is 2cm; the power of ultrasonic soaking is 350W, and the ultrasonic frequency is 30kHz; the concentration of the mixed solution is 20g / L;

[0033] Step 2, using a twin-screw extrusion extruder to extrude and expand the pretreated rice husk to obtain puffed rice husk; the sleeve temperature of the twin-screw extrusion extruder is 75°C, the screw speed is 120r / min, and the die aperture is 25mm;

[0034]Step 3. Add 12g of rice husk puffed product, 1g of methyl acrylate and 3g of allyl...

Embodiment 3

[0038] A preparation method for a biomass adsorption material for heavy metal treatment in domestic sewage, comprising the following steps:

[0039] Step 1. Treat 200g rice husks in low-temperature corona irradiation equipment for 10min, then add 20g ammonium carbonate and 20g melamine in a mixed solution for ultrasonic soaking for 25min, and then filter to obtain pretreated rice husks; The atmosphere treated in the lighting equipment is air, the temperature is 25°C, the voltage is 18KV, and the distance is 5cm; the power of ultrasonic soaking is 350W, and the ultrasonic frequency is 30kHz; the concentration of the mixed solution is 20g / L;

[0040] Step 2, using a twin-screw extruder to extrude and expand the pretreated rice husk to obtain puffed rice husk; the sleeve temperature of the twin-screw extruder is 60°C, the screw speed is 100r / min, and the die aperture is 15mm;

[0041] Step 3. Add 20g of rice husk puffed product, 2g of methyl acrylate and 6g of allyl thiourea int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com