Sewage treatment flocculant and preparation method thereof

A sewage treatment and flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, sustainable biological treatment, etc., can solve problems such as secondary pollution, non-conforming to green sustainable development, human health threats, etc., and achieve high use value , The removal effect is obvious and the performance is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

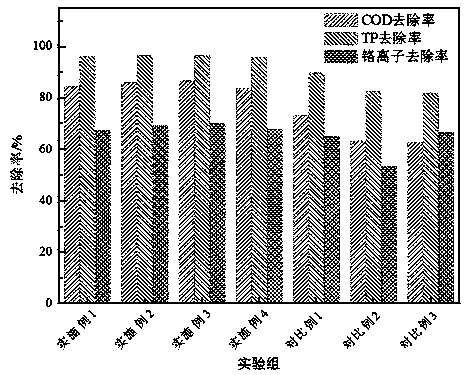

Examples

Embodiment 1

[0022] A preparation method of a sewage treatment flocculant, comprising the steps of:

[0023] (1) Configure the aqueous solution of chitosan acetic acid and iridium chloride, the concentration of each component in the aqueous solution of chitosan acetic acid and iridium chloride is respectively: chitosan acetic acid 10g / L, iridium chloride 2g / L , and the rest is water; stir the solution for 5 minutes, then add Span 80 and polyethylene glycol ethanol solution to the solution to form a mixed solution, wherein the concentration of each component in the Span 80 and polyethylene glycol ethanol solution is respectively It is: Span 80 is 20mL / 100mL, polyethylene glycol 2000 is 6mL / 100mL, and the rest is ethanol; the mixing volume ratio of aqueous solution of chitosan acetic acid and iridium chloride / Span 80 and polyethylene glycol ethanol solution =1:0.6. Keep the temperature of the mixed solution in a water bath at 55±5°C, stir continuously during the constant temperature process...

Embodiment 2

[0031] A preparation method of a sewage treatment flocculant, comprising the steps of:

[0032](1) Configure the aqueous solution of chitosan acetic acid and iridium chloride, the concentration of each component in the aqueous solution of chitosan acetic acid and iridium chloride is respectively: chitosan acetic acid 13g / L, iridium chloride 3g / L , and the rest is water; stir the solution for 5 minutes, then add Span 80 and polyethylene glycol ethanol solution to the solution to form a mixed solution, wherein the concentration of each component in the Span 80 and polyethylene glycol ethanol solution is respectively It is: Span 80 is 24mL / 100mL, polyethylene glycol 2000 is 8 mL / 100mL, and the rest is ethanol; the mixed volume of chitosan acetic acid and iridium chloride aqueous solution / Span 80 and polyethylene glycol ethanol solution Ratio=1:0.7. Keep the temperature of the mixed solution in a water bath at 55±5°C, stir continuously during the constant temperature process, and...

Embodiment 3

[0040] A preparation method of a sewage treatment flocculant, comprising the steps of:

[0041] (1) Configure the aqueous solution of chitosan acetic acid and iridium chloride, the concentration of each component in the aqueous solution of chitosan acetic acid and iridium chloride is respectively: chitosan acetic acid 17g / L, iridium chloride 5g / L , and the rest is water; stir the solution for 5 minutes, then add Span 80 and polyethylene glycol ethanol solution to the solution to form a mixed solution, wherein the concentration of each component in the Span 80 and polyethylene glycol ethanol solution is respectively For: Span 80 is 30mL / 100mL, polyethylene glycol 2000 is 12 mL / 100mL, and the rest is ethanol; the mixed volume of chitosan acetic acid and iridium chloride aqueous solution / Span 80 and polyethylene glycol ethanol solution Ratio=1:0.8. Keep the temperature of the mixed solution in a water bath at 55±5°C, stir continuously during the constant temperature process, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com