Preparation method of microbial sewage purification treatment agent

A technology for sewage purification and microorganisms, which is applied in the field of preparation of microbial sewage purification treatment agents, can solve the problems of poor removal of organic wastewater, inability to degrade organic pollutants, and single function, and achieves good biocompatibility and increased specific surface area. , the effect of hydrophilic enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

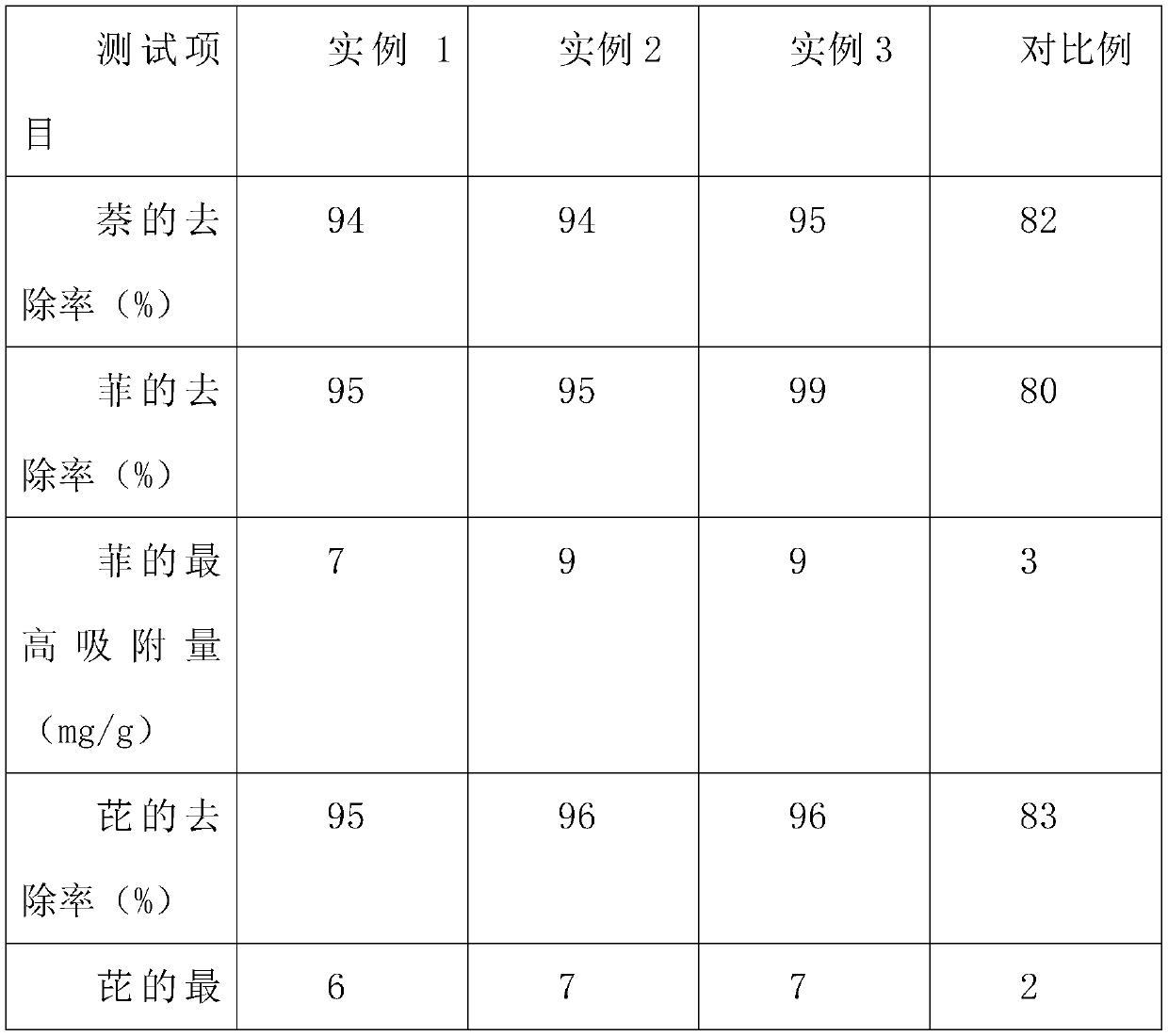

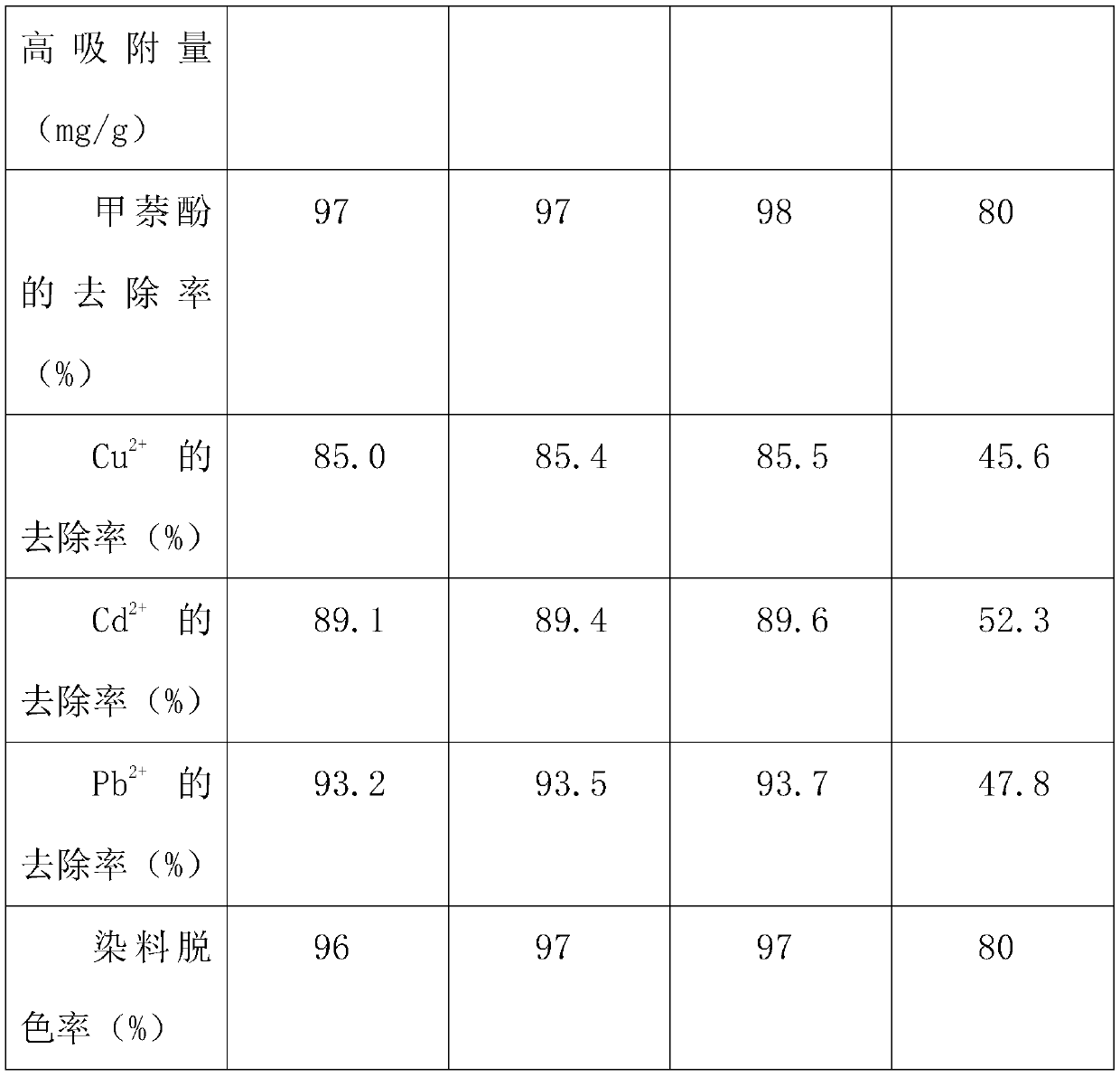

Examples

example 1

[0026] In parts by weight, put 20 parts of precipitating agent and 4 parts of composite carbonizing agent into 95 parts of hot water at 70°C, stir and let it stand for 2 hours, remove the upper liquid, collect the lower sediment, and pass the precipitant through Fly ash, lapis lazuli, and coke are mixed in a mass ratio of 5:2:1, placed in a muffle furnace, heated to 400°C, and roasted for 3 hours. The composite carbonizing agent is ammonium bicarbonate and hydrogen octahydrate It is prepared by mixing strontium oxide at a mass ratio of 5:1; mix the above-mentioned lower sediment, phenol, furfural, and sodium carbonate at a mass ratio of 3:4:5:1, put it into a reaction kettle, and heat up to 50°C , heat preservation reaction for 10 hours to obtain phenolic gel, aging for 10 hours to obtain a gel doped with strontium carbonate, and then put it in a carbonization furnace for carbonization in an argon atmosphere, control the carbonization temperature to 280 ° C, and the carbonizati...

example 2

[0028] In parts by weight, put 23 parts of precipitating agent and 5 parts of composite carbonizing agent into 98 parts of hot water at 75°C, stir and let it stand for 3 hours, remove the upper liquid, collect the lower sediment, and pass the precipitant through Fly ash, lapis lazuli, and coke are mixed in a mass ratio of 5:2:1, placed in a muffle furnace, heated to 450°C, and roasted for 4 hours. The composite carbonizing agent is ammonium bicarbonate and hydrogen octahydrate It is prepared by mixing strontium oxide at a mass ratio of 5:1; mix the above-mentioned lower sediment, phenol, furfural, and sodium carbonate at a mass ratio of 3:4:5:1, put it into a reaction kettle, and heat up to 53°C , heat preservation reaction for 11 hours to obtain phenolic gel, aging for 11 hours to obtain a gel doped with strontium carbonate, and then as for the carbonization furnace, carbonization was carried out in an argon atmosphere, the carbonization temperature was controlled at 300 ° C, ...

example 3

[0030] In parts by weight, put 25 parts of precipitating agent and 6 parts of composite carbonizing agent into 100 parts of hot water at 80°C, stir and let stand for 3 hours, remove the upper liquid, collect the lower sediment, and pass the precipitant through Fly ash, lapis lazuli, and coke are mixed in a mass ratio of 5:2:1, placed in a muffle furnace, heated to 500°C, and roasted for 4 hours. The composite carbonizing agent is ammonium bicarbonate and octahydrous hydrogen It is prepared by mixing strontium oxide at a mass ratio of 5:1; mix the above-mentioned lower sediment, phenol, furfural, and sodium carbonate at a mass ratio of 3:4:5:1, put it into a reaction kettle, and heat up to 55°C , heat preservation reaction for 12 hours, to obtain phenolic gel, aging for 12 hours, to obtain a gel doped with strontium carbonate, and then to carbonize in a carbonization furnace in an argon atmosphere, control the carbonization temperature to 330 ° C, and the carbonization time to 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com