Si-containing high-strength low-modulus medical titanium alloy and additive manufacturing method and application thereof

An additive manufacturing, titanium alloy technology, applied in the field of additive manufacturing of high-strength and low-modulus medical titanium alloy implants, can solve problems such as deterioration of mechanical properties and formability, and achieve improved yield strength, low elastic modulus, resistance to The effect of increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for additive manufacturing of Si-containing high-strength low-modulus medical titanium alloy, comprising the following steps:

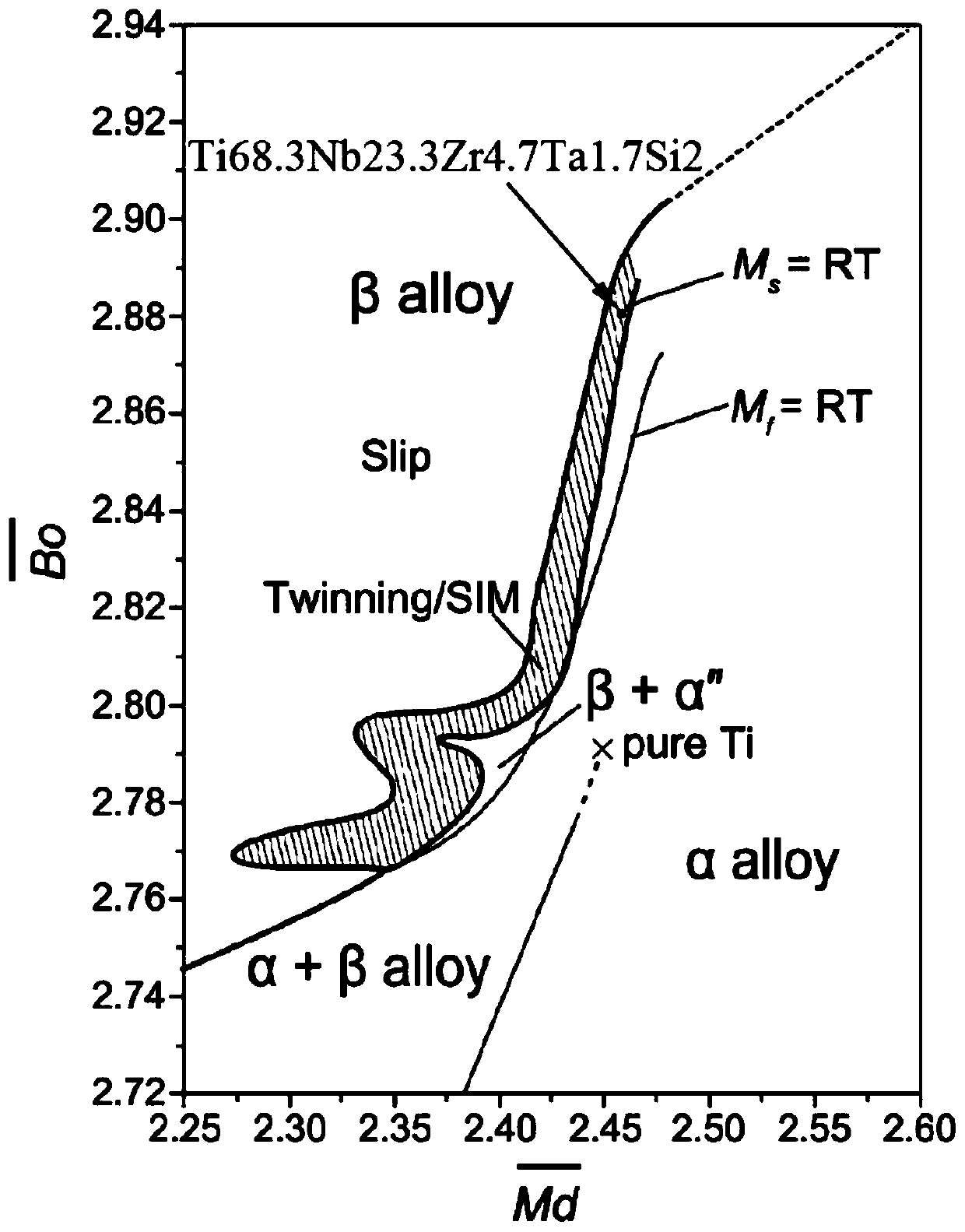

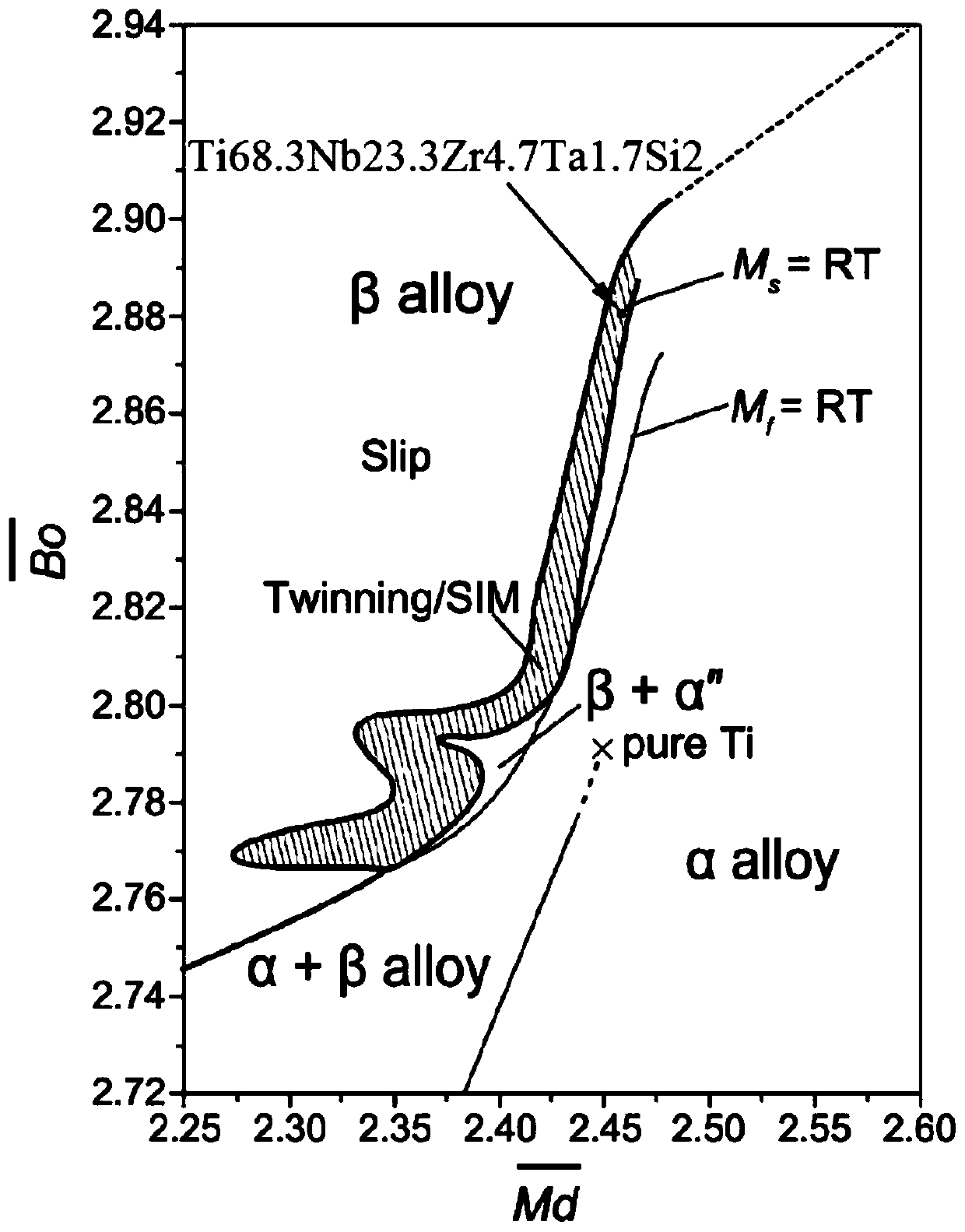

[0040] (1) Alloy composition design: based on the alloy composition ratio of Ti68.3at.%, Nb23.3at.%, Zr4.7at.%, Ta1.7at.%, Si2at.%, among them, Bo=2.88, Md=2.46 ,satisfy The metastable β-Ti region in the relationship diagram (attached figure 1 The position of the middle arrow is determined by Bo=2.88, Md=2.46), and the atomic percentage of each alloy can be determined by and Determined, use sponge titanium, sponge zirconium, tantalum-niobium master alloy (solid solution of niobium and tantalum), and silicon as raw materials to prepare alloy components; figure 1 for Relationship diagram (Scripta Materialia 158(2019) 62-65), where the shaded part is the metastable β-Ti region.

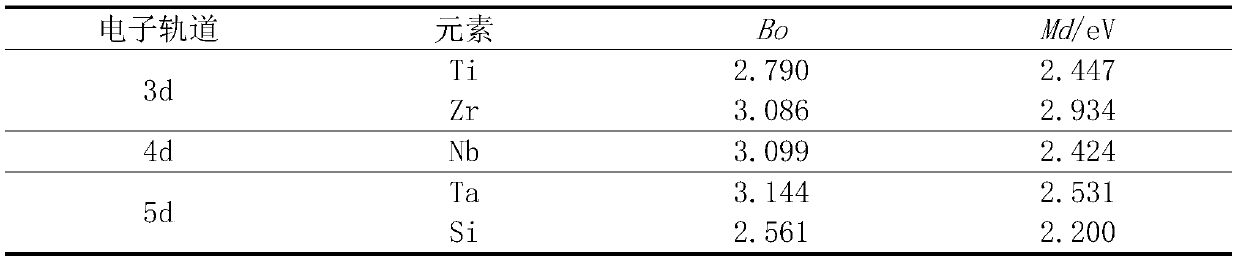

[0041] Table 1 Bo, Md values of different alloying elements in bcc-Ti

[0042]

[0043] Table 1 shows the Bo value and Md value of each alloy elem...

Embodiment 2

[0052] A method for additive manufacturing of Si-containing high-strength low-modulus medical titanium alloy, comprising the following steps:

[0053] (1) Alloy composition design: based on the alloy composition ratio of Ti68.3at.%, Nb23.3at.%, Zr4.7at.%, Ta1.7at.%, Si2at.%, among them, Bo=2.88, Md=2.46 ,satisfy In the metastable β-Ti region in the relationship diagram, the alloy components are prepared with sponge titanium, sponge zirconium, tantalum-niobium master alloy, and silicon monomer as raw materials;

[0054] (2) Flour making: the elements of Ti, Nb, Zr, Ta and Si are batched according to the content of step (1), and smelted in a vacuum consumable arc smelting furnace with a smelting speed of 20kg / min and remelted twice. Obtain an ingot with no obvious segregation in composition, machine the metal ingot into a round bar of φ60mm×650mm, remove the surface oxide skin, and prepare alloy powder by plasma rotating electrode atomization powder making method (PREP), the a...

Embodiment 3

[0059] A method for additive manufacturing of Si-containing high-strength low-modulus medical titanium alloy, comprising the following steps:

[0060] (1) Alloy composition design: with the alloy composition ratio of Ti69.6at.%, Nb23.7at.%, Zr4.8at.%, Ta1.7at.%, Si0.1at.%, among them, Bo=2.88, Md =2.47, satisfy In the metastable β-Ti region in the relationship diagram, the alloy components are prepared with sponge titanium, sponge zirconium, and tantalum-niobium master alloy as raw materials;

[0061] (2) Flour making: the elements of Ti, Nb, Zr, Ta and Si are batched according to the content of step (1), and smelted in a vacuum consumable arc smelting furnace with a smelting speed of 20kg / min and remelted twice. Obtain an ingot with no obvious segregation in the composition, machine the metal ingot into a round bar of φ45mm×550mm, remove the surface scale, and prepare alloy powder by electrode induction melting gas atomization method (EIGA), the atomization pressure is 4.0M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com