Grape juice yeast strain with low higher alcohol yield and strong malic acid degradation and application of grape juice yeast strain

A grape juice yeast and yeast strain technology, applied in the fields of bioengineering and genetic engineering, can solve problems such as fermentation obstruction, wine disease, delay, etc., achieve broad market prospects, shorten the fermentation cycle, and eliminate the effects of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

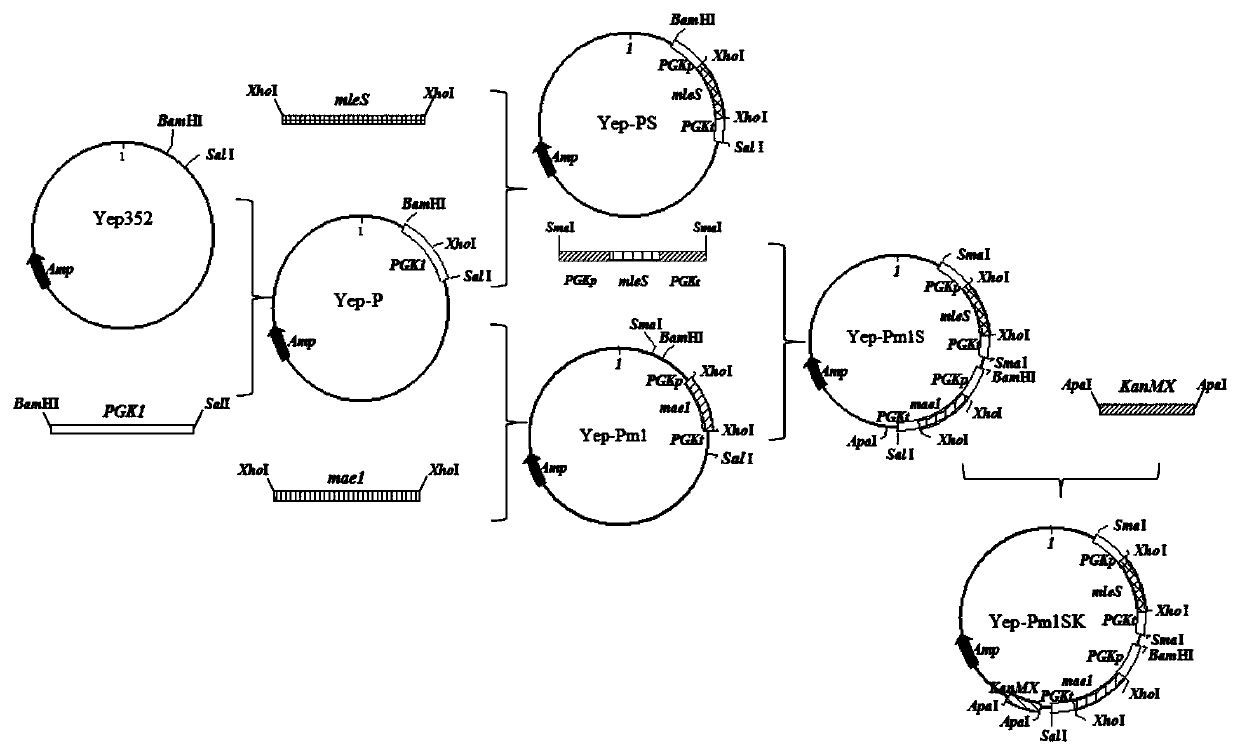

[0045] Construction of grape juice yeast overexpressing malate permease and malolactase

[0046] (1) Construction of recombinant plasmid Yep-KPm1S

[0047] The construction process of the recombinant plasmid Yep-Pm1 is as follows: figure 1 shown;

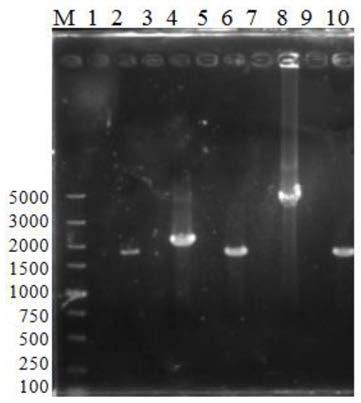

[0048] Using the plasmid pPGK1 as a template, PGK-F (SEQ ID NO:5) and PGK-R (SEQ ID NO:6) as primers, PCR amplifies the PGK1 gene fragment (SEQ ID NO:4), PCR reaction conditions: 95°C 5min; 94°C for 40s, 56°C for 1min, 72°C for 108s, 30 cycles; 72°C for 10min. Plasmid Yep532 and PGK1 gene fragments were digested with restriction endonucleases BamHI and SalI, and the two were ligated to construct plasmid Yep-P; using the genome of Schizosaccharomyces pombe CICC1757 strain as a template, mae1-F (SEQ ID NO: 7) and mae1-R (SEQ ID NO: 8) as primers, PCR amplified fragment mae1 (SEQ ID NO: 1), PCR reaction conditions: 95°C for 5min; 94°C for 40s, 56°C for 1min, 72°C for 108s, 30 cycles; 10 min at 72°C. The fragment was ligated with t...

Embodiment 2

[0054] Fermentation Experiment of Grape Juice Yeast Strain with Low Production of Higher Alcohol

[0055] (1) Wine fermentation experiments of recombinant strains and starting strains

[0056] ①Fermentation process roadmap:

[0057] Grape raw materials; screening, cleaning, drying, destemming; crushing; sugar adjustment, acid adjustment; adding sulfurous acid, sterilization; inoculation; pre-fermentation; skin residue separation; determination indicators.

[0058] ②Process conditions: sugar content: 20.45Brix; acidity: pH 3.5; SO 2 Dosage: 80mg / L, let stand at 4°C for 12h; liquid volume: 190mL grape juice in a 250mL triangular bottle; inoculation volume: 1×10 8 CFU / mL; fermentation temperature and time: 25°C, 5 days; wine steaming conditions: 100mL fermentation broth, add 100mL water, steam 100mL wine sample.

[0059] Carry out wine fermentation experiment to grape juice yeast starting strain CICC1465 and the bacterial strain WY-m1S of selection embodiment according to abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com