Hydrophobic starch-fiber composite foam material and preparation method thereof

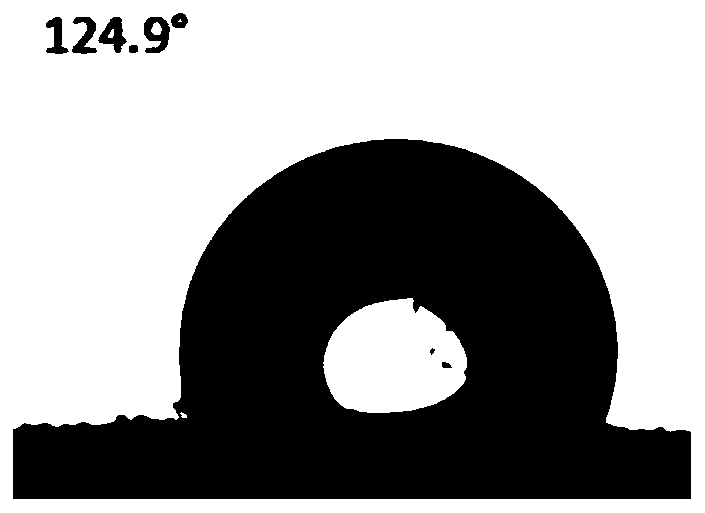

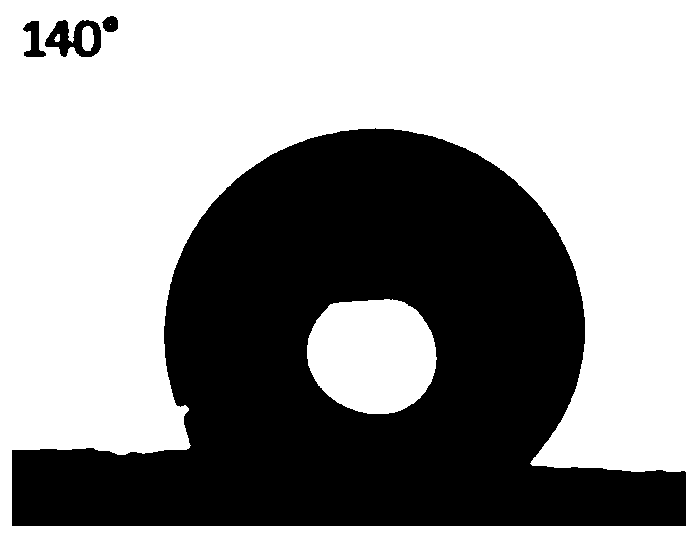

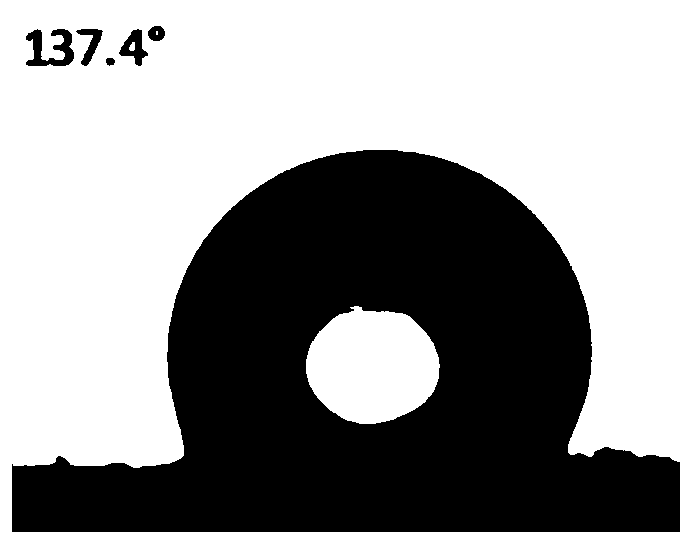

A fiber composite, hydrophobic starch technology is applied in the field of foam material preparation, which can solve the problems of non-renewable raw materials and poor degradation treatment, and achieve the effects of improving binding adsorption performance, uniform distribution, and increasing hydrophobic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A kind of preparation method of hydrophobic starch fiber composite foam material is characterized in that, comprises the following steps:

[0043] 1) In terms of parts by mass, weigh 100 parts of starch, 10-50 parts of plant fiber, 10-30 parts of plasticizer, 1-10 parts of filler, 1-5 parts of silane coupling agent and 0.5-2.5 parts of hydrophobic agent. share;

[0044] 2) Use a fiber disintegrator to disintegrate the plant fibers into single, wet fibers, then beat to 45°SR to 90°SR, and sieve through a 200-mesh screen to obtain fine fibers for subsequent use;

[0045] 3) mixing starch and a plasticizer, and performing gelatinization treatment to obtain gelatinized starch;

[0046] 4) adding the aqueous solution of the filler into the gelatinized starch, stirring evenly to obtain sample A;

[0047] 5) Adjust the temperature to 75°C, add silane coupling agent and hydrophobic agent to sample A, stir evenly, and obtain sample B;

[0048] 6) adding fine fibers into sampl...

Embodiment 1

[0057] 1) 10 parts of cotton plant fibers are decomposed and refined to 45 ° SR, and then sieved through a 200-mesh screen to obtain fine fibers for subsequent use;

[0058] 2) Mix 100 parts of tapioca starch and 10 parts of glycerin, add an appropriate amount of distilled water and stir evenly, and perform gelatinization treatment with a stirrer at a low stirring speed at 85° C. to obtain gelatinized tapioca starch;

[0059] 3) Take another 5 parts of calcium carbonate and ultrasonically disperse in water to obtain a dispersion liquid, add the dispersion liquid to the above-mentioned gelatinized tapioca starch and stir evenly to obtain sample A;

[0060] 4) Adjust the stirring temperature to 75°C, add 1 part of silane coupling agent and 0.5 part of stearic acid to sample A and stir evenly to obtain sample B;

[0061] 5) adding fine fibers into sample B, and uniformly mixing at a higher stirring speed to obtain sample C;

[0062] 6) Pour sample C into the mold, cool to room t...

Embodiment 2

[0090] 1) 30 parts of hardwood plant fibers are decomposed and refined to 67 ° SR, and then sieved by 200 mesh screens to obtain fine fibers for subsequent use;

[0091] 2) Mix 100 parts of wheat starch and 20 parts of ethylene glycol, add an appropriate amount of distilled water and stir evenly, and perform gelatinization treatment with a stirrer at a low stirring speed at 85°C to obtain gelatinized wheat starch;

[0092] 3) Another part of talcum powder was ultrasonically dispersed in water to obtain a dispersion liquid, which was added to the above-mentioned gelatinized wheat starch and stirred evenly to obtain sample A;

[0093] 4) Adjust the stirring temperature to 75°C, add 2.5 parts of silane coupling agent and 1.5 parts of stearic acid to sample A and stir evenly to obtain sample B;

[0094] 5) adding fine fibers into sample B, and uniformly mixing at a higher stirring speed to obtain sample C;

[0095] 6) Pour sample C into the mold, cool to room temperature, refrige...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com