Mineral-based organic soil conditioner and preparation method thereof

An organic soil and conditioner technology, applied in the field of pesticides, can solve the problems of destroying soil balance, affecting crop growth, lack of minerals, etc., and achieve the effects of improving precipitation utilization efficiency, increasing soil water erosion resistance, and reducing soil erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

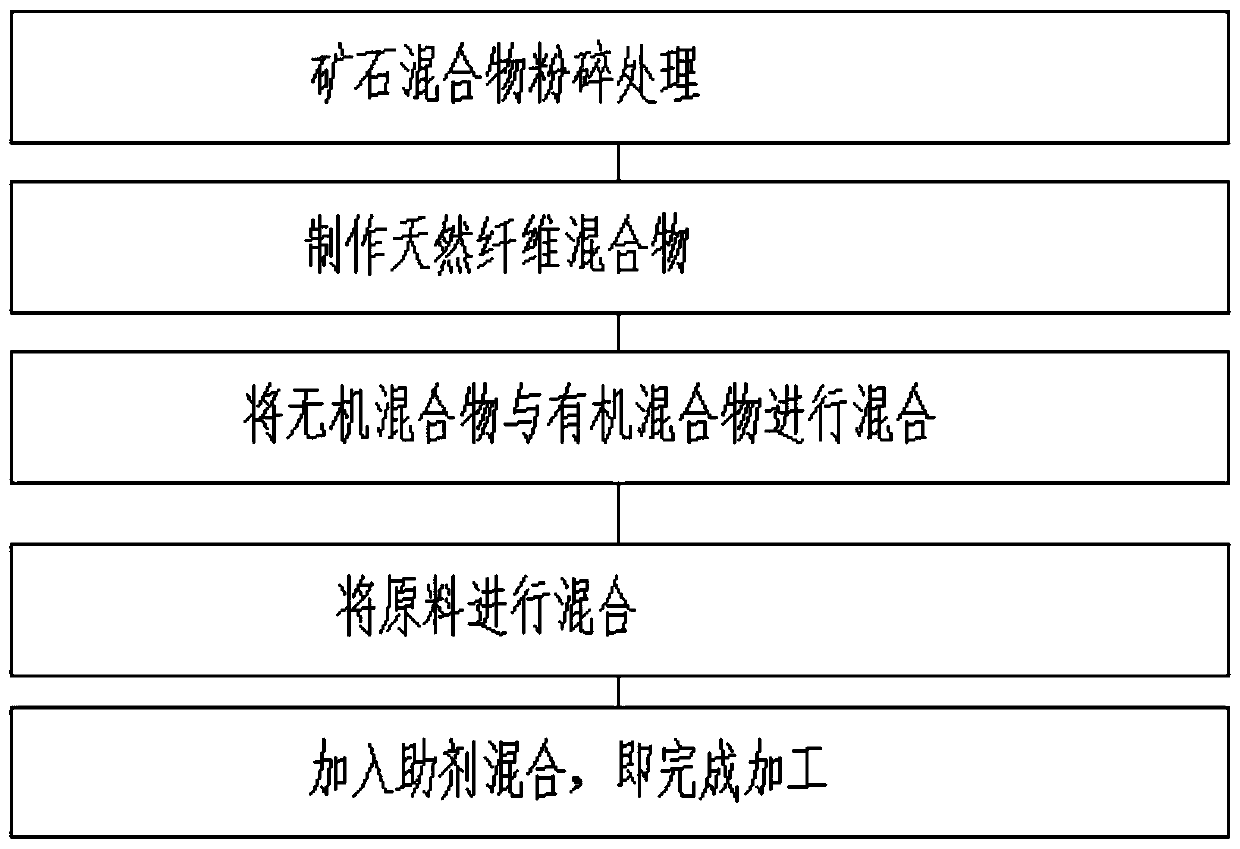

Method used

Image

Examples

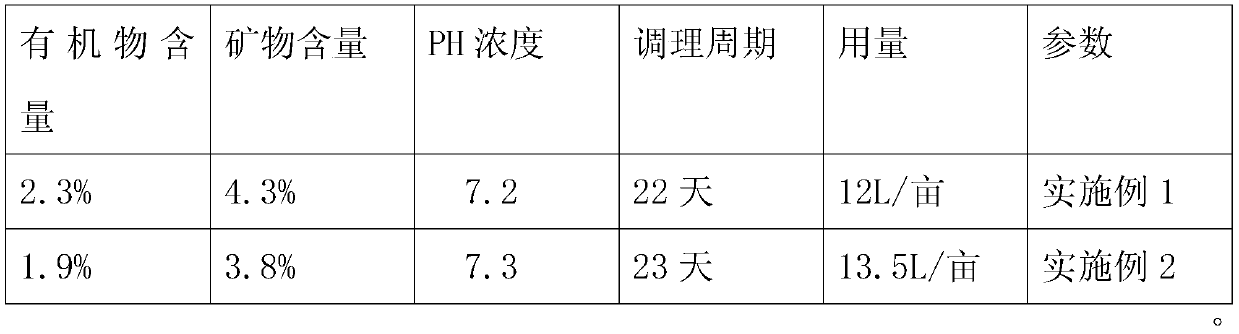

Embodiment 1

[0038] The proportion of the ore mixture is set to 15%, the proportion of the natural fiber mixture is set to 25%, the proportion of the inorganic salt mixture is set to 42%, and the proportion of the organic mixture is set to 10%. The proportion is set to 8%.

[0039] The ore mixture is pulverized first, and perlite, zeolite, sepiolite, vermiculite, clay minerals, feldspar minerals, magnesium aluminum hydrotalcite, medical stone are fully pulverized;

[0040] Then make a natural fiber mixture, crush leguminous straw, corn straw, cotton straw, and sawdust, and then carry out sealed fermentation treatment;

[0041] Then mix the inorganic mixture with the organic mixture, sodium chloride, calcium chloride, ferric chloride, ferric sulfate, manganese sulfate, zinc sulfate, potassium nitrate, magnesium nitrate, copper nitrate, calcium nitrate, magnesium carbonate, sodium carbonate and Polyacrylamide, humic acid, ammonia water, urea, polyacrylic acid, vinyl acetate maleic acid, pol...

Embodiment 2

[0045] The proportion of the ore mixture is set to 5%, the proportion of the natural fiber mixture is set to 10%, the proportion of the inorganic salt mixture is set to 25%, and the proportion of the organic mixture is set to 5%. The proportion is set to 2%.

[0046] The ore mixture is pulverized first, and perlite, zeolite, sepiolite, vermiculite, clay minerals, feldspar minerals, magnesium aluminum hydrotalcite, medical stone are fully pulverized;

[0047]Then make a natural fiber mixture, crush leguminous straw, corn straw, cotton straw, and sawdust, and then carry out sealed fermentation treatment;

[0048] Then mix the inorganic mixture with the organic mixture, sodium chloride, calcium chloride, ferric chloride, ferric sulfate, manganese sulfate, zinc sulfate, potassium nitrate, magnesium nitrate, copper nitrate, calcium nitrate, magnesium carbonate, sodium carbonate and Polyacrylamide, humic acid, ammonia water, urea, polyacrylic acid, vinyl acetate maleic acid, polyvi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com