Method for preparing antibacterial agent by immobilizing Chinese herbal medicines with attapulgite

A technology of attapulgite and Chinese herbal medicine, which is applied in the directions of pharmaceutical formulations, medical preparations without active ingredients, and medical preparations containing active ingredients, etc., can solve the problems of easy oxidation of Chinese herbal medicine extracts, and achieve good water solubility and thermal stability. properties, realize industrialized production, and have the effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

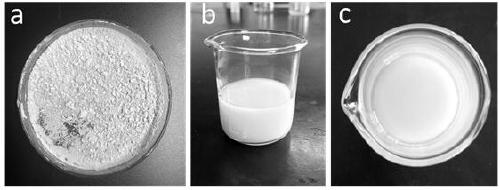

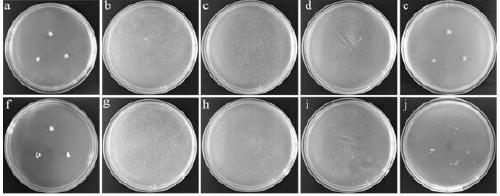

Embodiment 1

[0030] Spray 5% Scutellaria baicalensis extract relative to the mass fraction of attapulgite on the surface of attapulgite under stirring, then place it in a ball mill, and grind for 30 minutes at a ball-to-material ratio of 1:10. Put the mixed material in a stirring tank, spray 20% hot-melt monoglyceride laurate relative to the mass fraction of attapulgite, and then spray 1% N-trimethyl chitosan oligosaccharide relative to the mass fraction of attapulgite into the mixture The aqueous solution of sugar quaternary ammonium salt is continuously stirred for 30 minutes after spraying, and then it is placed in a roller machine for roller treatment, and the material is dried, crushed, and packaged to obtain the product.

Embodiment 2

[0032] Spray 7.5% Astragalus extract relative to the mass fraction of attapulgite on the surface of attapulgite under stirring, then place it in a ball mill, and grind for 30 minutes at a ball-to-material ratio of 1:10. Put the mixed material in a stirring tank, spray 15% hot-melt monocapric laurate relative to the mass fraction of attapulgite, and then spray 1.5% N-alkylated shell relative to the mass fraction of attapulgite into the mixture The aqueous oligosaccharide quaternary ammonium salt solution was continuously stirred for 30 minutes after spraying, and then it was placed in a counter-roll machine for counter-roll processing, and the material was dried, crushed, and packaged to obtain the product.

Embodiment 3

[0034] Spray 10% astragalus extract relative to the mass fraction of attapulgite on the surface of attapulgite under stirring, then place it in a ball mill, and grind for 30 minutes at a ball-to-material ratio of 1:10. Put the mixed material in a mixing tank, spray 10% glyceryl monomyristate and 10% monoglyceride laurate relative to the mass fraction of attapulgite, and then spray 2% relative to the mass fraction of attapulgite into the mixture The carboxymethylhydroxypropyltrimethylammonium chloride chitosan oligosaccharide aqueous solution is continuously stirred for 30 minutes after spraying, and then it is placed in a roller machine for roller treatment, and the material is dried, crushed, and packaged to obtain the product .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com