A stabilizer for repairing heavy metal chromium pollution and its preparation method and application

A technology of stabilizer and heavy metal, applied in the field of stabilizer for repairing heavy metal chromium pollution and its preparation, can solve the problems of low stabilization efficiency, short stabilization period and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

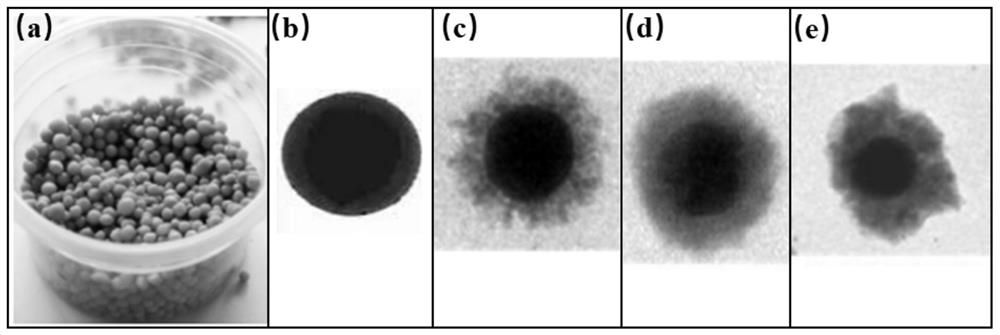

[0044] A preparation method for a stabilizer for repairing heavy metal chromium pollution, comprising the following steps:

[0045] 1) Mix the following agents that have been fully dried according to the following mass ratio, calcium polysulfide: reduced iron powder: wheat bran = 3:1:1, and put them into a ball mill mixer to quickly mix evenly. Stored in a dry environment for later use, the reducing agent prepared at this stage is recorded as reducing agent 1.

[0046] The calcium polysulfide added during the preparation of the reducing agent needs to be dried in a blast drying oven at 45°C for 4 hours. The purity of the calcium polysulfide is industrially pure crystals with a purity greater than 50%. Wheat bran is a by-product of flake wheat flour. The added The moisture content of wheat bran must not exceed 2%; the particle size of the above-mentioned reduced iron powder is more than 400 mesh, and the iron content must be greater than 85%.

[0047] 2) Add 2.65% to 4.4% of b...

Embodiment 2

[0057] Preliminary experiment: Screening and ratio selection experiment of the effective components of the reducing agent in the reducing core:

[0058] 1. Stabilization efficiency experiment of single-component reducing agent on chromium-contaminated soil:

[0059] Table 1: Experimental results of stabilization efficiency of single-component reducing agent on chromium-contaminated soil

[0060]

[0061] The above table 1 shows that the soil stabilization experiments were carried out on the single components of the reducing inner core agent. The hexavalent chromium leaching concentration blank control value of the untreated soil was 28.2mg / L. After adding different dosages of the single agent, The concentration of leached hexavalent chromium in the soil has been reduced to a certain extent, and the use of calcium polysulfide component has the highest degree of stabilization of the soil, and the concentration of leached hexavalent chromium has been reduced to below the detec...

Embodiment 3

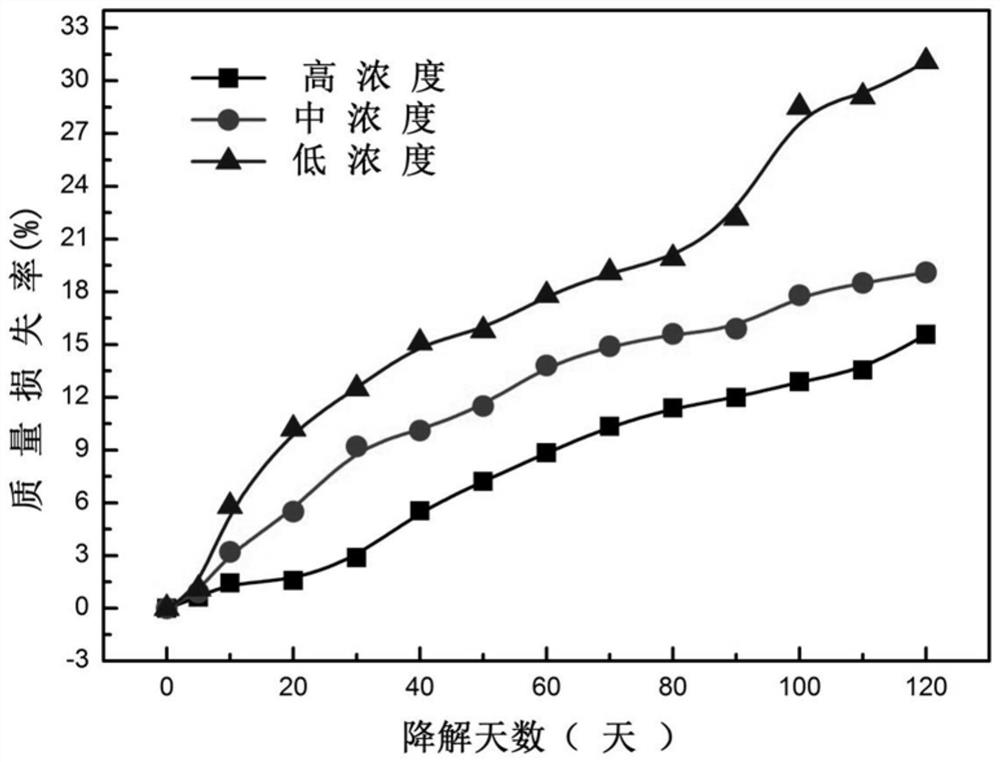

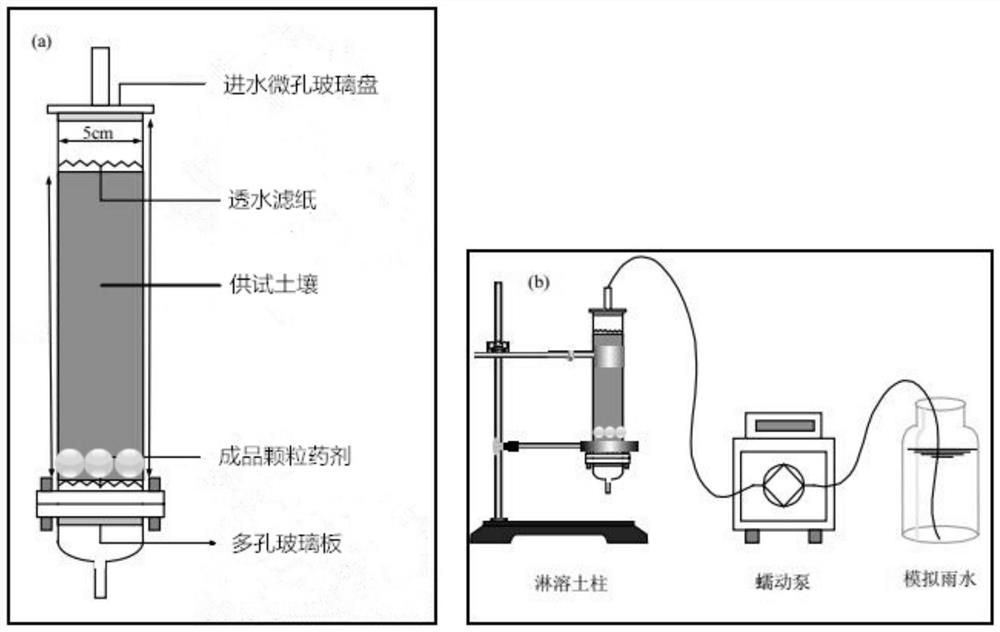

[0067] Verification experiment of biodegradable outer film:

[0068]The verification experiment of the degradable biological outer membrane is mainly demonstrated through the membrane biodegradation experiment, and the implementation process is as follows: in the membrane biodegradation experiment, the membrane liquid is cast on a horizontal glass plate, and the thickness of the membrane is kept within the range of 0.1-0.2mm. The film was cut into small square pieces of 2cm*2cm, and the weight of the film was weighed with a ten-thousand-digit balance and the serial number was recorded. Parallel experiments were performed on different concentrations of the film solution, and each sample was processed 3 times. In the experiment, the numbered square membranes were buried in the experimental soil at the same time and in order (Note: The membrane material needs to be soaked in water before being embedded in the soil, and the membrane material should be placed in deionized water at r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com