Alkaline water electrolysis total battery

A technology of water electrolysis cell and full battery, which is applied in the direction of electrolysis process, electrolysis components, electrodes, etc., can solve the problems such as difficult to achieve high-efficiency catalysis, and achieve the effect of stable structure and catalytic performance, high stability and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

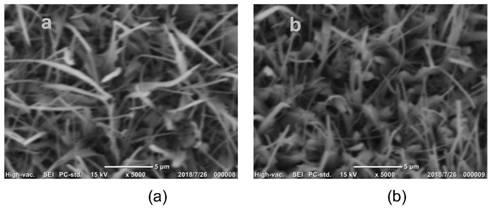

[0047] 1. Electrode material pretreatment: nickel content ≥ 99.5%, thickness 100 microns, area 10 cm 2 The nickel sheet is used as the base material, firstly through 800# and 1200# # Polish the surface with water abrasive paper until the surface is smooth, then soak it in acetone at room temperature for 15 minutes to remove the surface grease; finally soak it in 0.5M hydrochloric acid aqueous solution for 20 minutes to remove the surface scale, and then rinse with a large amount of deionized water To neutral, dry with high-purity Ar gas;

[0048] 2. Electroplating solution preparation: to analyze pure grade CoSO 4 ·7H 2 O and CoCl 6H 2 O as Co salt, H 3 BO 3 As a pH stabilizer, prepare 230ml electroplating solution with ultrapure water with a resistivity of 18.2MΩ, and control the CoSO in the plating solution 4 ·7H 2 O, CoCl 6H 2 O and H 3 BO 3 The concentrations are 0.5M, 0.2M and 0.1M, respectively.

[0049] 3. Electrodeposition of Co particles: First, under the s...

Embodiment 2

[0055] 1. Electrode material pretreatment: nickel content ≥ 99.5%, thickness 50 microns, area 10 cm 2 The nickel sheet is used as the base material, firstly through 800# and 1200# # Polish the surface with water abrasive paper until the surface is smooth, then soak it in acetone at room temperature for 15 minutes to remove the surface grease; finally soak it in 0.5M hydrochloric acid aqueous solution for 30 minutes to remove the surface scale, and then rinse with a large amount of deionized water To neutral, dry with high-purity Ar gas;

[0056] 2. Electroplating solution preparation: to analyze pure grade CoSO 4 ·7H 2 O and CoCl 6H 2 O as Co salt, H 3 BO 3 As a pH stabilizer, prepare 230ml electroplating solution with ultrapure water with a resistivity of 18.2MΩ, and control the CoSO in the plating solution 4 ·7H 2 O, CoCl 6H 2 O and H 3 BO 3 The concentrations are 0.3M, 0.1M and 0.5M, respectively.

[0057] 3. Electrodeposition of Co particles: First, under the st...

Embodiment 3

[0061] 1. Electrode material pretreatment: nickel content ≥ 99.5%, thickness 1mm, area 10cm 2 The nickel sheet is used as the base material, firstly through 800# and 1200# #Polish the surface with water abrasive paper until the surface is smooth, then soak it in acetone at room temperature for 30 minutes to remove surface grease; finally soak it in 0.5M hydrochloric acid aqueous solution for 30 minutes to remove surface oxide skin, and then rinse with a large amount of deionized water To neutral, dry with high-purity Ar gas;

[0062] 2. Electroplating solution preparation: to analyze pure grade CoSO 4 ·7H 2 O and CoCl 6H 2 O as Co salt, H 3 BO 3 As a pH stabilizer, prepare 230ml electroplating solution with ultrapure water with a resistivity of 18.2MΩ, and control the CoSO in the plating solution 4 ·7H 2 O, CoCl 6H 2 O and H 3 BO 3 The concentrations are 1.0M, 0.5M and 0.3M, respectively.

[0063] 3. Electrodeposition of Co particles: First, under the stirring condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com