Preparation method of high-capacity linear supercapacitor electrode based on MXene/PANI

A supercapacitor and high-capacity technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of limiting rate performance, reducing the specific surface area of electrodes, and poor mechanical properties, so as to achieve good electrochemical performance and improve Active surface area, favorable transport effect

- Summary

- Abstract

- Description

- Claims

- Application Information

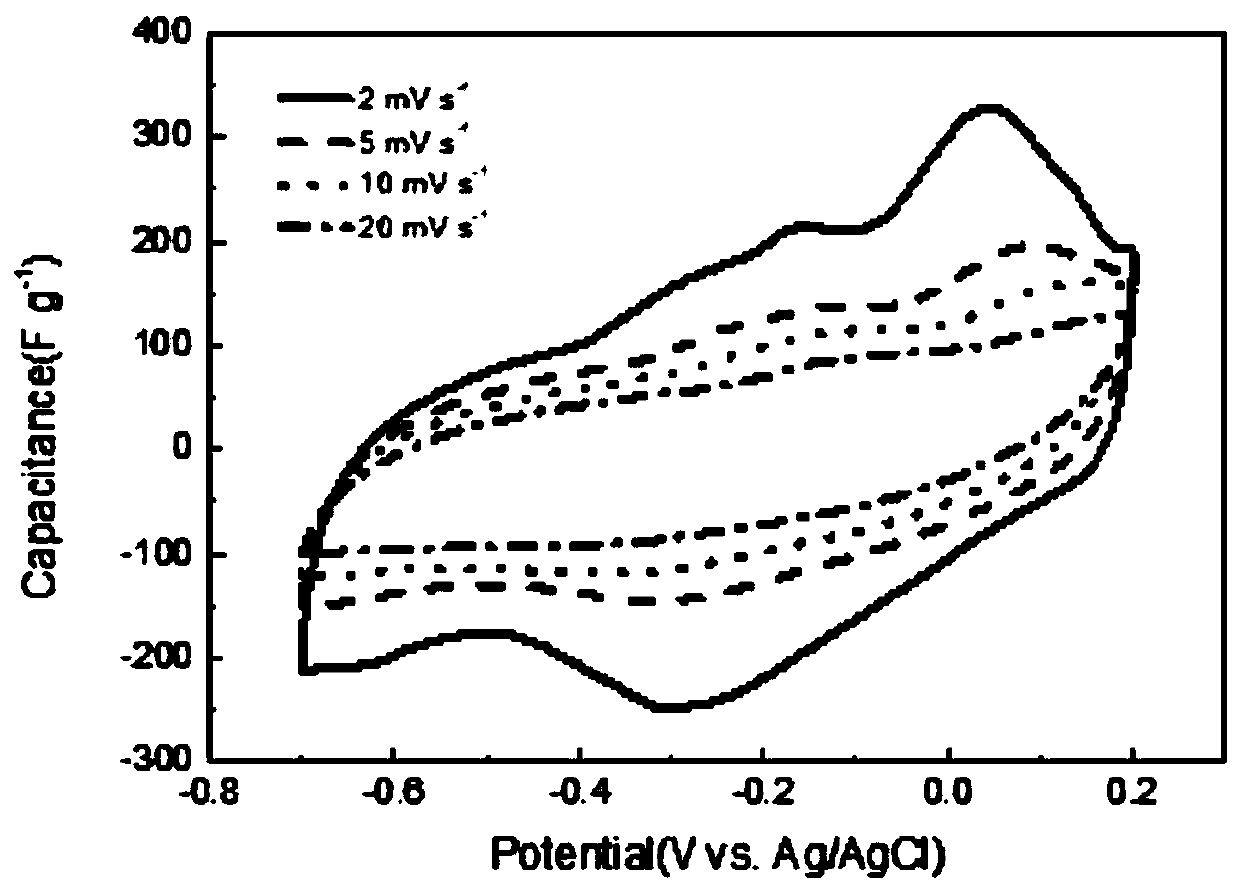

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Take 1g of lithium fluoride, add 20ml of hydrochloric acid with a concentration of 9mol / L and stir evenly, then slowly add 1g of precursor V 2 AlC, stirred at 40°C for 24 hours, washed and dried to obtain V 2 C MXene powder, the resulting powder was added to deionized water to form a 10mg / ml suspension, and the resulting solution was centrifuged after ultrasonic pulverization at 700W under an argon protective atmosphere and an ice bath environment, and the supernatant was taken to obtain V 2 C MXene Monodispersion.

[0027] (2) Add aniline 10% by volume to 1mol / L dilute hydrochloric acid, stir and mix evenly, and then add V with a concentration of 2mg / ml obtained in step (1). 2 C MXene monodisperse, V 2 The volume ratio of C MXene monodispersion to the hydrochloric acid solution of aniline is 1:2 (33% MXene). After stirring at 0°C for 4 hours, the MXene / PANI precipitate was obtained. The precipitate was repeatedly washed with deionized water and dried. Obtain MXe...

Embodiment 2

[0032] (1) Take 2g of lithium fluoride, add 20ml of hydrochloric acid with a concentration of 9mol / L and stir evenly, then slowly add 2g of precursor Ti 3 AlC 2 , stirred at 40°C for 24h, washed and dried to obtain Ti 3 C2 MXene powder, the obtained powder was added to deionized water to form a 10mg / ml suspension, and the obtained solution was ultrasonically pulverized at 900W under an argon atmosphere and an ice bath environment, and the resulting solution was centrifuged, and the supernatant was taken to obtain a MXene monodispersion.

[0033] (2) Add 5% of aniline to 1mol / L dilute hydrochloric acid by volume ratio, stir and mix evenly, and then add in the MXene monodispersion with a concentration of 4mg / ml obtained in step (1), the volume ratio of MXene monodispersion to aniline hydrochloric acid solution 1:1 (50% MXene), stirred at -5°C for 4 hours to obtain MXene / PANI precipitate, washed the precipitate repeatedly with deionized water and dried to obtain MXene / PANI powd...

Embodiment 3

[0038] (1) Take 1g of lithium fluoride, add 20ml of hydrochloric acid with a concentration of 9mol / L and stir evenly, and at the same time add 1g of precursor Ti 3 AlC 2 , stirred at 40°C for 24h, washed and dried to obtain Ti 3 C 2 MXene powder, the obtained powder was added to deionized water to form a 10mg / ml suspension, and the obtained solution was ultrasonically pulverized at 900W under an argon atmosphere and an ice bath environment, and the resulting solution was centrifuged, and the supernatant was taken to obtain a MXene monodispersion.

[0039] (2) Add aniline 5% by volume in 1mol / L dilute hydrochloric acid, stir and mix evenly and add in the MXene monodispersion with a concentration of 4mg / ml obtained in step (1), the volume of the hydrochloric acid solution of MXene monodispersion and aniline The ratio is 1:3 (25% MXene). After stirring at 0°C for 4 hours, the MXene / PANI precipitate was obtained. The precipitate was repeatedly washed with deionized water and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com