Catalytic material, preparation method thereof and photocatalyst

A technology of catalytic materials and powders, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as narrow pH range, low cycle efficiency, low photocatalytic quantum efficiency, etc., to achieve Effects of widening pH range, high cycle efficiency, and increasing degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A kind of catalytic material, concrete preparation method is as follows:

[0044] 1) Weigh 0.6g of urea and 3g of citric acid monohydrate at room temperature (the molar ratio of urea to citric acid monohydrate is 71%), add them to 30mL of deionized water and stir to obtain a uniform mixed solution, put it in a microwave oven Carry out microwave heating and baking to obtain a yellow-black viscous liquid, then put it in an oven to dry at 85°C, and grind to obtain a powder; then add the powder to deionized water for stirring and dissolving, and the obtained solution is dialyzed with a 200D dialysis membrane , put into an oven after dialysis, dry at 80°C, and grind to obtain N-CQDs powder;

[0045] 2) Weigh 2.3665 g of ferric chloride and 4.3775 g of copper sulfate pentahydrate, put them into 300 mL of deionized water together, stir with a magnetic stirrer until completely dissolved, obtain a uniform first solution, and record it as liquid A;

[0046] 3) Weigh 3g of NaOH a...

Embodiment 2

[0050] Weigh 2.3665g of ferric chloride and 4.3775g of copper sulfate pentahydrate at room temperature, put them into 300mL of deionized water, stir with a magnetic stirrer until completely dissolved, and record it as liquid A; then weigh 3g of sodium hydroxide and dissolve it in 200mL The alkaline solution obtained in deionized water is recorded as liquid B; a small amount of liquid B is added dropwise to 600mL of deionized water to make the pH about 9, which is recorded as liquid C; Stirring, at the same time, slowly drop the A liquid into the C liquid, and drop the B liquid at the same time to keep the pH at about 9, obtain the second solution after the end of the drop A liquid, and heat and concentrate the second solution to 80mL, stop heating, continue to stir for 12h to make it age, then put it into a polytetrafluoroethylene reactor, and conduct a hydrothermal reaction at a temperature of 105°C for 8 hours. Wash with water to make the pH of the supernatant after centrifu...

Embodiment 3

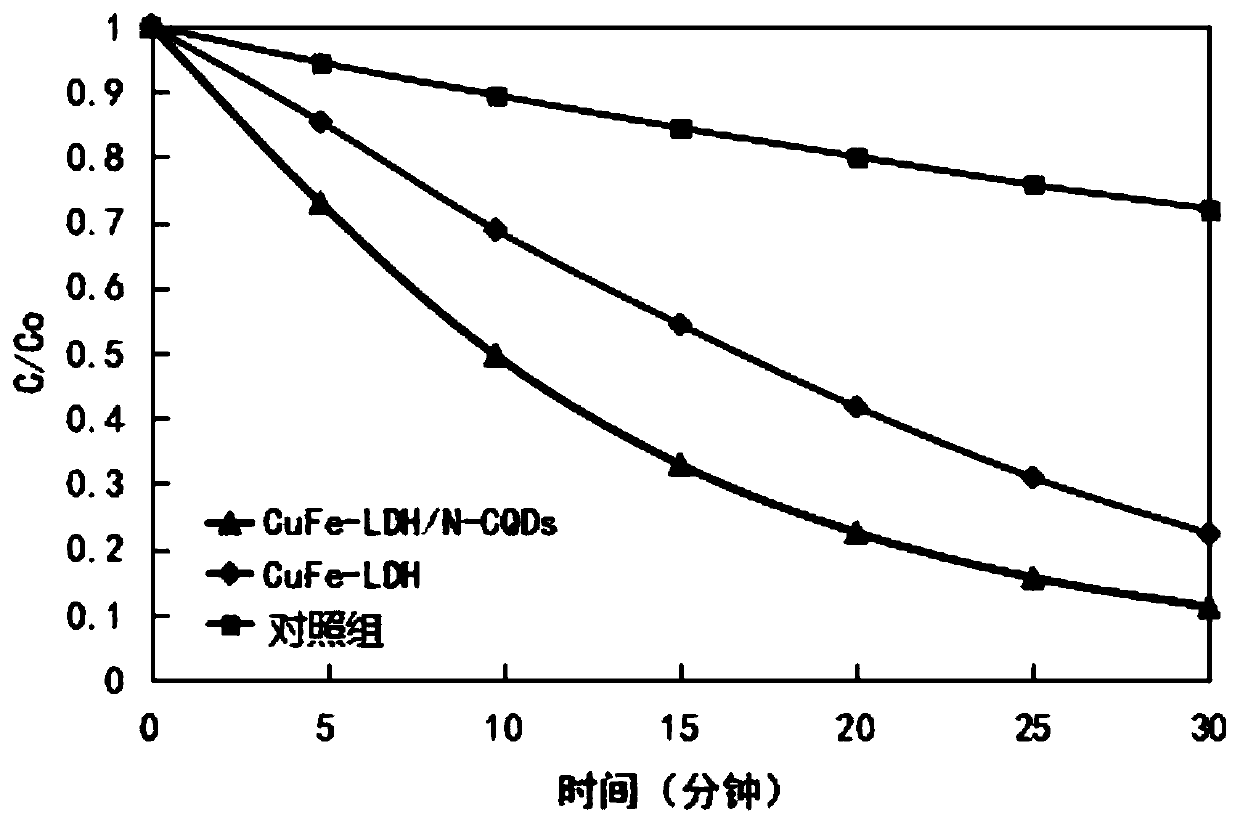

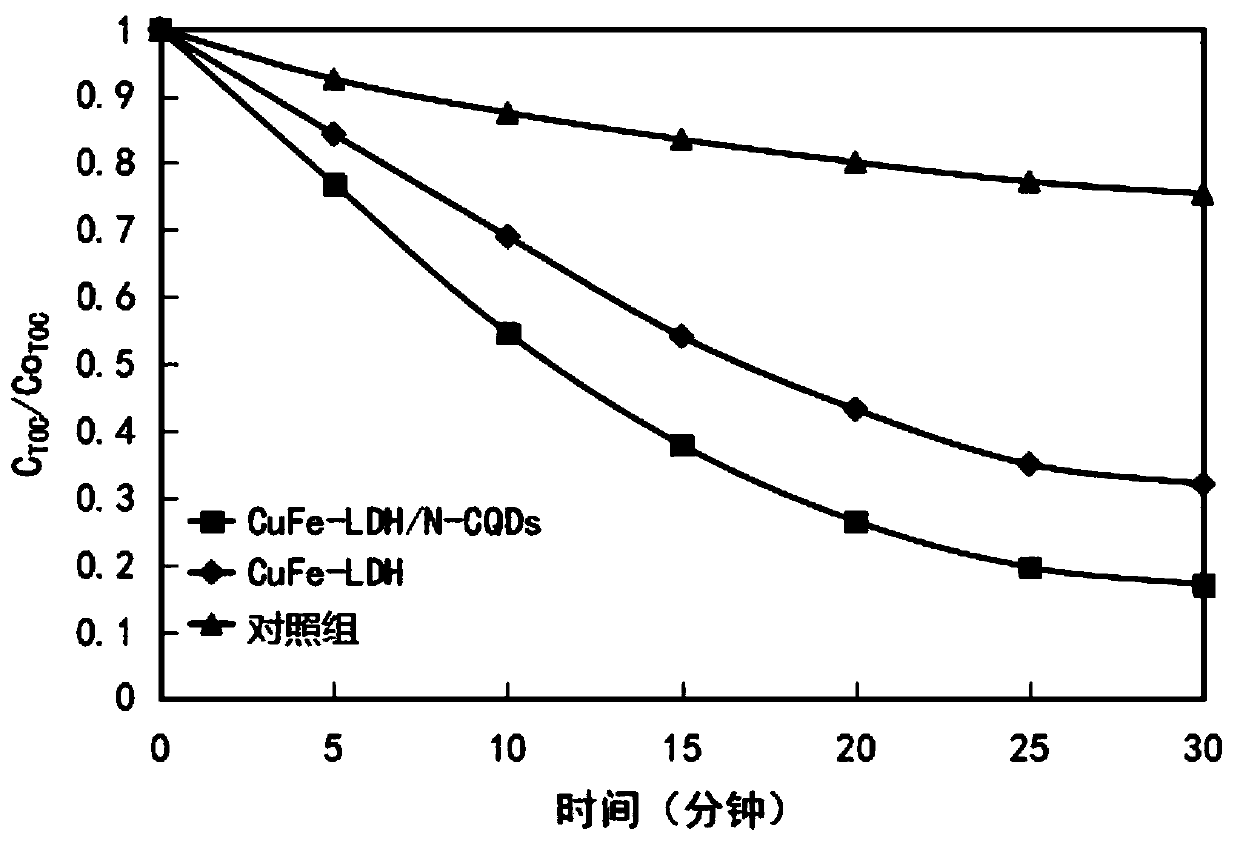

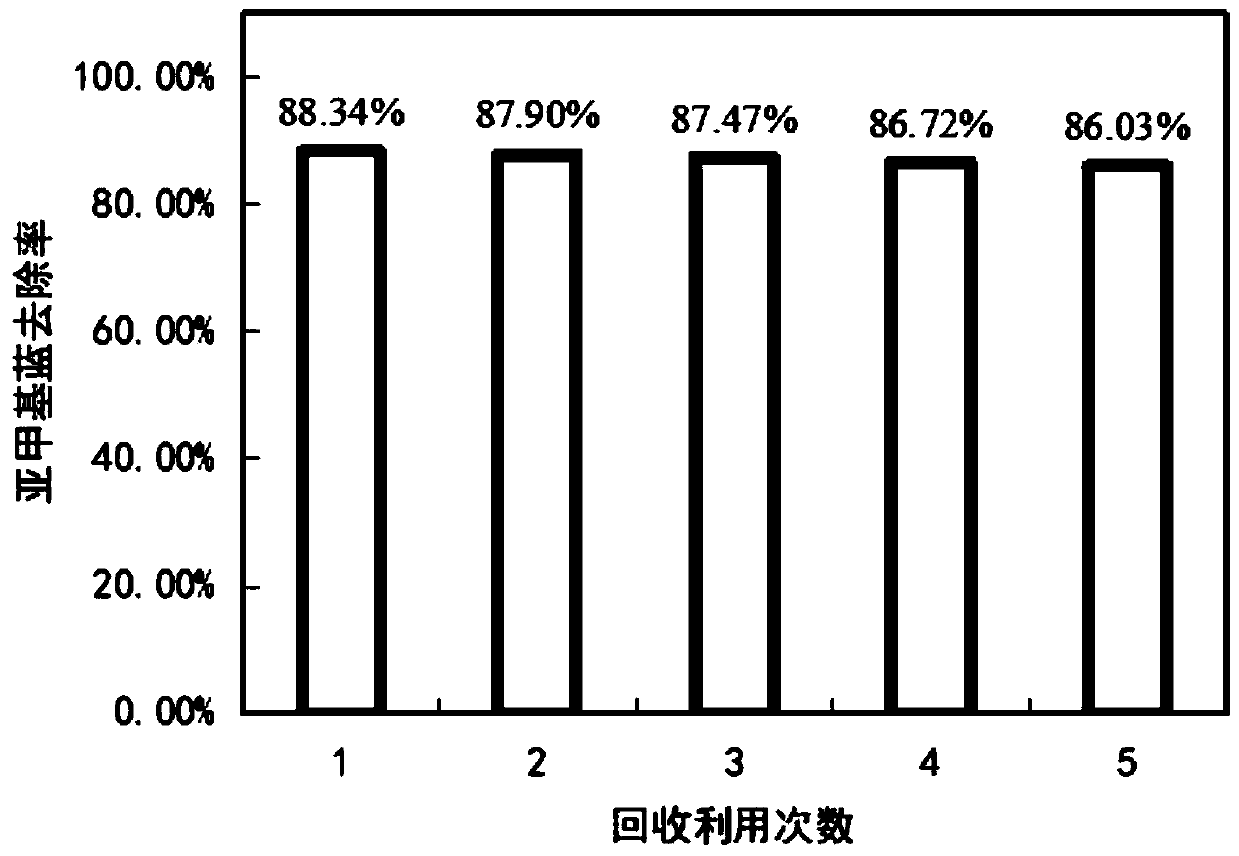

[0052] The CuFe-LDH / N-CQDs prepared in Example 1 and the CuFe-LDH prepared in Example 2 are carried out the photo-Fenton reaction degradation MB (MethyleneBlue, methylene blue) test, specifically, the methylene blue that takes concentration is 10mg / L Put 80mg of the solution into a 100mL small beaker, add 100μL of H 2 o 2 and 0.003g of the test sample (the CuFe-LDH / N-CQDs prepared in Example 1 or the CuFe-LDH prepared in Example 2), then stir with a magnetic stirrer and irradiate the simulated sunlight with a 500W xenon lamp to provide a light source, each Take a sample every 5 minutes, react for 0.5 hours altogether, test the absorbance (λ=664) of each sample with a UV spectrophotometer, and also test the total organic carbon (TOC, Total organic carbon) concentration of the MB solution during the photodegradation process Dynamic monitoring was carried out; at the same time, a control group that kept other conditions and operating steps unchanged except for the addition of te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com