Wall breaking agent for sludge, hydrophobic skeleton, preparation method and sludge reduction method

A sludge and hydrophobic technology, which is applied in the field of wall-breaking agents and hydrophobic frameworks for sludge treatment, and sludge reduction in sewage plants, can solve the problems of high cost of additional carbon sources, few practical applications, and high requirements for operation and management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

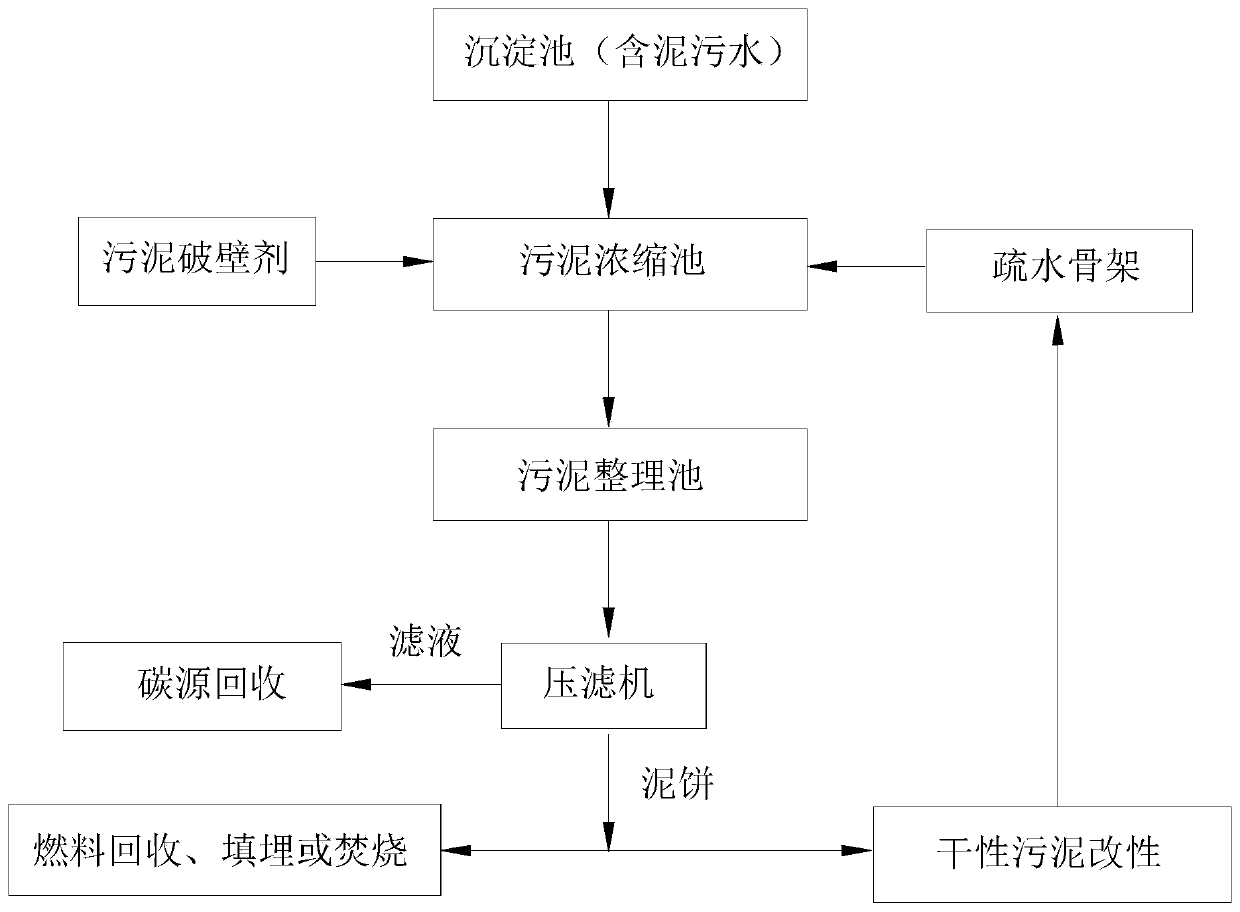

Method used

Image

Examples

preparation example Construction

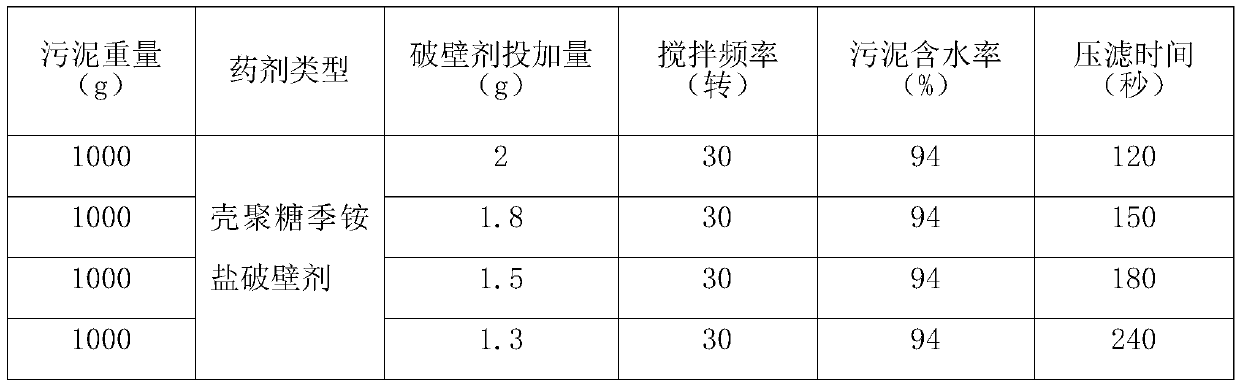

[0066] The preparation method of the above-mentioned wall-breaking agent embodiment is to use hydroxypropyl chitosan as a targeting agent, 2.2-dibromo-3-cyanopropionamide as an organic bromine fungicide, and decynediol or polyoxygen Vinyl fatty alcohol ether is used as a penetrating agent, glutaraldehyde is used as a crosslinking agent, and it is prepared after compounding in a certain order and proportion. The overall process is simple, no special equipment is needed, the process parameters are easy to control, and the cost is low.

[0067] The present invention also provides a hydrophobic framework, which is prepared by mixing biomass powder or sludge dewatered from a sewage treatment plant with the above-mentioned wall-breaking agent according to the following weight percentages as the filler base material, wherein :

[0068] Biomass powder or sludge after pressure filtration and dehydration in sewage treatment plants: 50-80%; wall breaking agent: 20-50%.

[0069] Specifi...

Embodiment 1

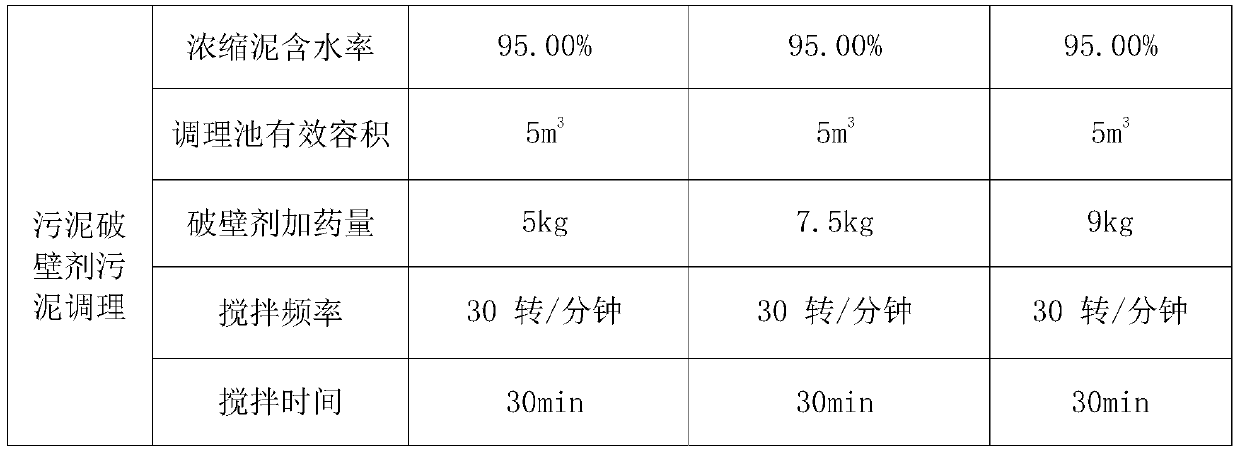

[0089] The sludge used in this example is municipal domestic sludge with an initial moisture content of 95%, an effective volume of the conditioning tank of 100 cubic meters, and a negative pressure of 0.1-0.16 MPa in the circulating pump.

[0090] 1. Experimental object:

[0091] A water purification plant in Shenzhen, covering a total area of 20,000m 2 , the sewage treatment scale is 50,000 m 3 / d, using the fast PIPR biochemical sewage treatment process, the effluent water quality meets the first-class A standard of the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002).

[0092] The plant's existing sludge dewatering process uses a thickening tank + plate-and-frame filter press.

[0093] 2. Preparation of sludge wall breaking agent:

[0094] S1 Mix and stir 1 kg of hydroxypropyl chitosan and 40 kg of deionized water to make a mixed solution A with a concentration of 2.5%;

[0095] S2 20 kg of bactericide (1-40% 2.2-dibromo-3-cyanopropion...

Embodiment 2

[0149] The sludge used in this embodiment is the sludge of rivers, rivers and lakes, the initial water content is 90%, and the suction pressure of the circulation pump is negative pressure 0.1-0.16Mpa.

[0150] The steps of reducing the amount of water-containing sludge in this embodiment:

[0151] S1 Mix 1 kg of hydroxypropyl chitosan and 10 kg of deionized water to make a mixed solution A with a concentration of 10%;

[0152] S2 30kg of bactericide (2.2-dibromo-3-cyanopropionamide of 1-40%), decynediol 1kg deionized water 139kg are evenly stirred to make (2.2-dibromo-3-cyanide of 21.42% concentration propionamide) mixed solution B;

[0153] S3 A mixed solution 11kg (10% concentration of hydroxypropyl chitosan aqueous solution) and B mixed solution (2.2-dibromo-3-cyanopropionamide of 21.42% concentration) 170kg are evenly stirred to make mixed solution C;

[0154] S4 Add 0.5kg of 1,2-pentanediol with a concentration of 1-10% to the mixed solution C in parts by weight, stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com