Preparation method of high-strength flame-retardant galactomannan-based composite membrane

A galactomannan and composite membrane technology, which is applied in the field of biomass synthesis composite materials, can solve the problems of small improvement in mechanical properties and low mechanical strength of the galactomannan membrane, and achieves high mechanical strength and flame retardancy. Good, good usability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Preparation of galactomannan / bentonite composite film

[0033] (1) Soak the air-dried Cinnamon seeds in hot water for 6 hours, separate the endosperm of the Cinnabar seeds from the rest, dry the obtained endosperm at 30° C., grind it mechanically, and pass through a 100-mesh sieve to obtain the Cinnabis endosperm powder. Mix the endosperm powder and distilled water at a solid-to-liquid ratio of 1:50, put it in an extraction tank, stir and extract at 50°C for 24 hours, centrifuge the extract at 5000r / min for 10 minutes to obtain a supernatant, and add the supernatant under stirring 3 times the volume of ethanol with a concentration of 95% was centrifuged at 10,000 r / min for 10 minutes to obtain a precipitate. The precipitate was washed 5 times with 95% ethanol, and the washed precipitate was freeze-dried to obtain galactomannan. The purity and molecular weight of galactomannans were determined.

[0034] (2) Add 2 g of galactomannan (GM) into 100 mL of dis...

Embodiment 2

[0039] Embodiment 2: Preparation of galactomannan / bentonite / graphene oxide composite film

[0040] (1) Prepare a galactomannan (GM) solution according to step (2) of Example 1.

[0041] (2) Bentonite (BNT) suspension was prepared according to step (3) of Example 1.

[0042] (3) Add 1 g of graphene oxide into 100 mL of distilled water, stir and sonicate, repeat 5 times, and centrifuge at 10,000 r / min for 10 min to obtain a uniform graphene oxide (GO) dispersion.

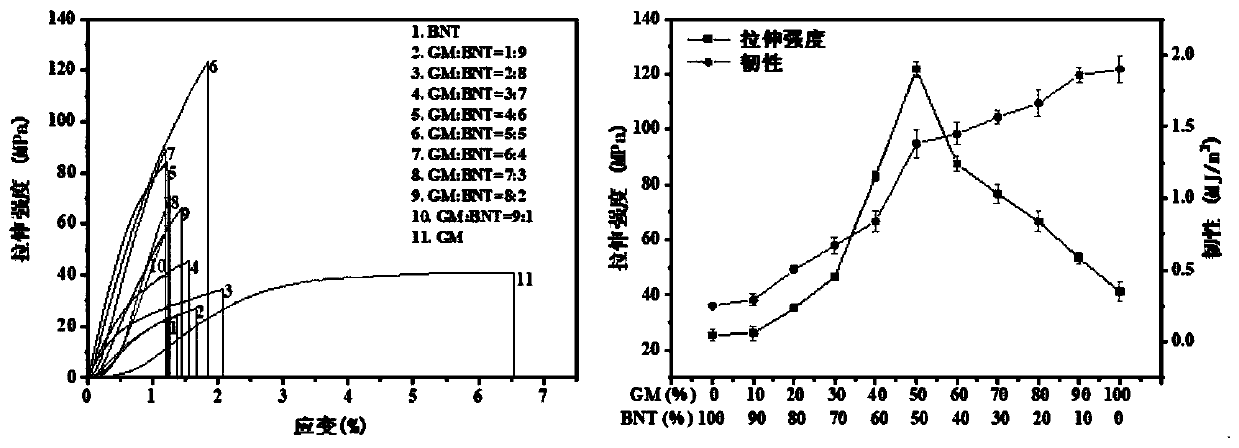

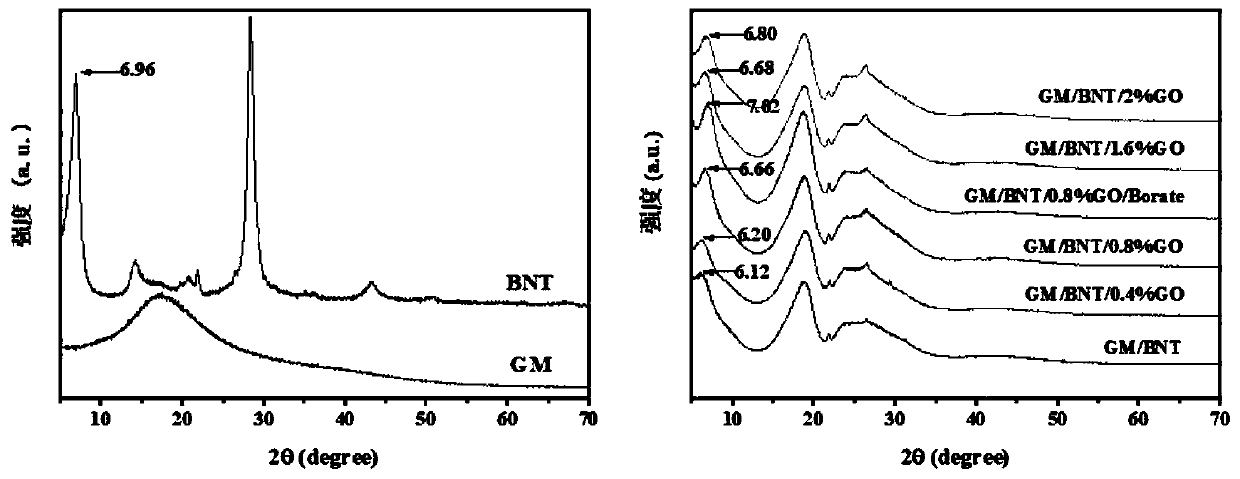

[0043] (4) Mix the galactomannan solution of step (1) and the bentonite suspension of step (2) at a mass ratio of GM and BNT of 5:5, and add 0.4wt%, 0.8wt%, 1.6wt% , 2% wt% graphene oxide dispersion, stirred for 24h, the composite solution obtained was added to a plastic plate, evaporated to dryness, and obtained galactomannan / bentonite / graphene oxide composite film (GM / BNT / GO composite film ).

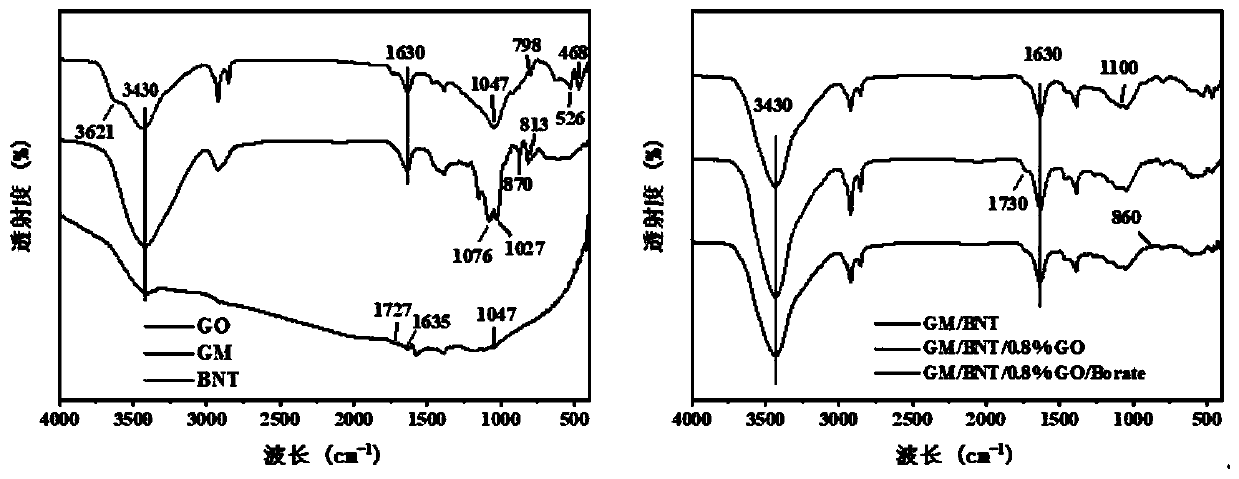

[0044] The results showed that in the infrared spectrum of GM / BNT / GO composite film ( figure 1 ), at 3430cm -1 The int...

Embodiment 3

[0046] Embodiment 3: Preparation of Galactomannan / Bentonite / Graphene Oxide / Borate Composite Film

[0047] (1) Prepare a galactomannan (GM) solution according to step (2) of Example 1.

[0048] (2) Bentonite (BNT) suspension was prepared according to step (3) of Example 1.

[0049] (3) Prepare a graphene oxide (GO) dispersion according to step (3) of Example 2.

[0050] (4) Dissolve 1 g of sodium tetraborate in 100 mL of distilled water to prepare a sodium tetraborate solution.

[0051] (5) Mix the galactomannan solution, bentonite suspension and graphene oxide solution prepared in steps (1), (2) and (3), and add 0.1wt% sodium tetraborate solution, and stir for 24h , adding the obtained composite solution to a plastic plate, and curing at 90° C. for 8 hours after evaporation and drying to obtain a galactomannan / bentonite / graphene oxide / borate composite film.

[0052] The results showed that in the infrared spectrum of GM / BNT / 0.8%GO / borate composite film ( figure 1 ), when t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com