Environment-friendly hot melt adhesive for wax cartons and preparation method thereof

A hot-melt adhesive and environment-friendly technology, applied in wax adhesives, adhesive types, adhesive additives, etc., can solve the problems of slow drying speed, complicated production process, and high temperature of hot-melt adhesives, and achieve fast adhesion The effects of joint operation, improved production efficiency, and short bonding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An environment-friendly hot-melt adhesive for waxed cartons, the preparation steps of which are as follows:

[0028] S1. Preparation of paraffin wax emulsion: put 16 parts of sliced paraffin and 4 parts of compound emulsifier B in a reaction vessel, and raise the temperature to 75°C. After the paraffin is completely melted, start stirring. After stirring for 10 minutes, add dropwise at a rate of 2.0 mL / min 80 parts of deionized water heated to 75°C, continue to heat and stir at 75°C for 30min, and then cool the prepared paraffin emulsion to room temperature for later use; wherein, the composite emulsifier B is an alkylphenol polymer with a weight ratio of 11:9 A mixture of oxyethylene ether and Span 80;

[0029] S2. Compound emulsion preparation: Mix 28 parts of vinyl acetate, 3 parts of methyl methacrylate, 7 parts of butyl acrylate and 2 parts of acrylic acid to obtain a monomer mixture; dissolve 0.3 parts of potassium persulfate in 15 parts of deionized Prepare th...

Embodiment 2

[0032] An environment-friendly hot-melt adhesive for waxed cartons, the preparation steps of which are as follows:

[0033] S1. Preparation of paraffin wax emulsion: put 16 parts of sliced paraffin and 10 parts of compound emulsifier B in a reaction vessel, and raise the temperature to 75°C. After the paraffin is completely melted, start stirring. After stirring for 10 minutes, add dropwise at a speed of 2.0 mL / min 74 parts of deionized water warmed up to 75°C, continue to heat and stir at 75°C for 45min, and then cool the prepared paraffin emulsion to room temperature for later use; wherein, the composite emulsifier B is an alkylphenol polymer with a weight ratio of 11:9 A mixture of oxyethylene ether and Span 80;

[0034] S2. Compound emulsion preparation: Mix 28 parts of vinyl acetate, 6 parts of methyl methacrylate, 4 parts of butyl acrylate and 2 parts of acrylic acid to obtain a monomer mixture; dissolve 0.2 parts of potassium persulfate in 15 parts of deionized Prepa...

Embodiment 3

[0037] An environment-friendly hot-melt adhesive for waxed cartons, the preparation steps of which are as follows:

[0038] S1. Preparation of paraffin emulsion: put 12 parts of sliced paraffin and 8 parts of compound emulsifier B in a reaction vessel, and raise the temperature to 75°C. After the paraffin is completely melted, start stirring. After stirring for 10 minutes, add dropwise at a rate of 2.0 mL / min 80 parts of deionized water warmed up to 75°C, continue to heat and stir at 75°C for 60min, and then cool the prepared paraffin emulsion to room temperature for later use; wherein, the composite emulsifier B is an alkylphenol polymer with a weight ratio of 11:9 A mixture of oxyethylene ether and Span 80;

[0039] S2. Prepare composite emulsion: Mix 22 parts of vinyl acetate, 7.2 parts of methyl methacrylate, 5.8 parts of butyl acrylate and 5 parts of acrylic acid to obtain a monomer mixture; dissolve 0.2 parts of potassium persulfate in 15 parts of deionized Prepare th...

PUM

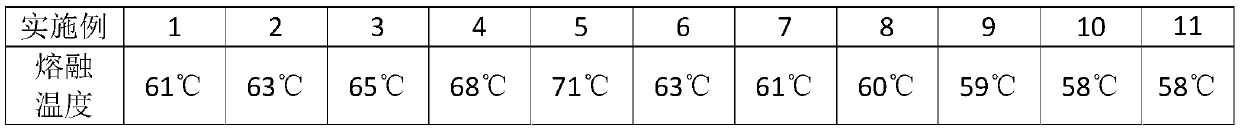

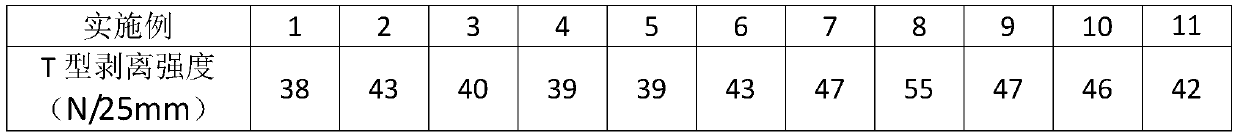

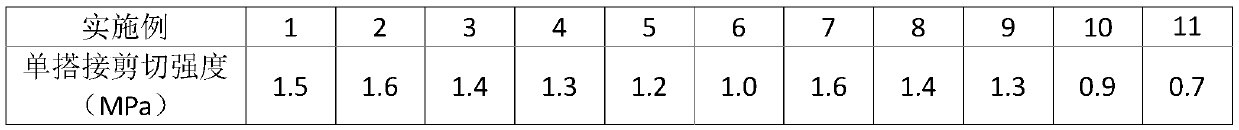

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com