Magnetic mesoporous composite material as well as preparation method and application thereof

A composite material and mesoporous technology, applied in the direction of microsphere preparation, chemical instruments and methods, microcapsule preparation, etc., can solve the problems of complex preparation process, small particle size, unsatisfactory adsorption and separation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

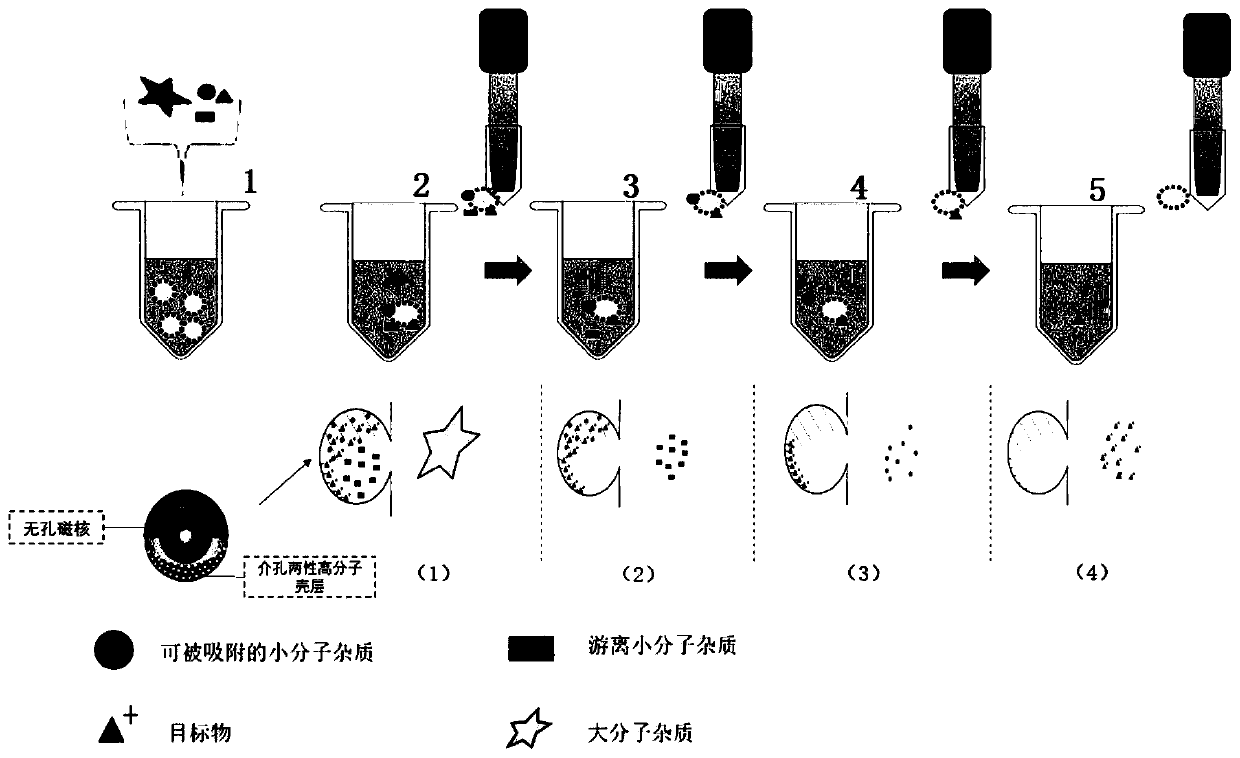

Method used

Image

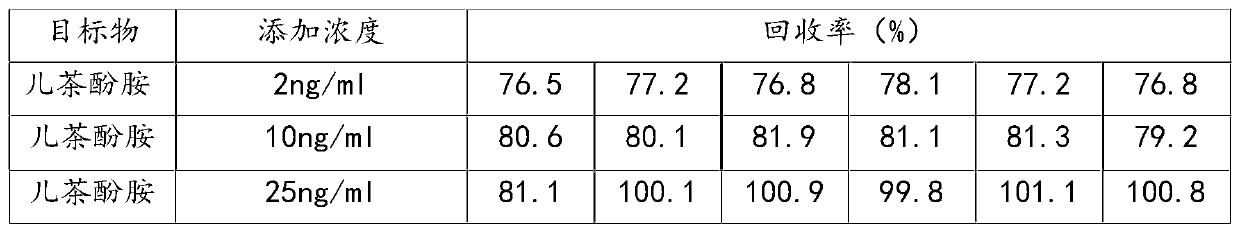

Examples

Embodiment 1

[0133] Example 1: Preparation of Monodisperse Hydrophobic Coated Magnetic Beads

[0134] Add 1 g of silica-coated iron oxide magnetic beads (average particle size 0.3 micron, Suzhou Beaver Biomedical Engineering Co., Ltd.), add 30 ml of 0.1N hydrochloric acid, heat to 50 ° C for 3 hours; take out the magnetic beads with a magnetic rod , washed 3 times with pure water, and dried with hot air; mix the above-mentioned treated magnetic beads with the following reagents: 0.3 g of octyltrimethoxysilane, 0.2 g of tetraethoxy silicon, 0.1 g of pure water, and 10 ml of toluene; Heated to reflux for 15 hours; the treated magnetic beads were taken out with a magnetic rod, and washed with ethanol and methanol for 3 times, 5 ml each time; vacuum-dried to obtain 1.3 g of monodisperse, hydrophobic magnetic beads (LM).

Embodiment 2

[0135] Example 2: Preparation of hydrophobic polymer-coated magnetic beads

[0136]Add 1 g of silica-coated iron oxide magnetic beads (average particle size 3 microns), add 30 ml of 0.1N hydrochloric acid, heat to 50°C for 3 hours; remove the magnetic beads with a magnetic rod, wash with pure water 3 times, and Blow dry; mix the above treated magnetic beads with the following reagents: 0.3 g of vinyltrimethoxysilane, 0.1 g of tetraethoxy silicon, 0.1 g of pure water, 10 ml of toluene; heat and reflux for 15 hours; The treated magnetic beads were taken out, washed with ethanol and methanol for 3 times, 5 ml each time; vacuum-dried to obtain 1.2 g of monodisperse, hydrophobic magnetic beads (LM2). Take 1 g of LM2, 0.1 g of AIBN, and 5 ml of n-hexane. After mixing, remove the n-hexane by rotary evaporation at room temperature; add 0.8 g of styrene, 0.4 g of divinylbenzene, and 20 ml of toluene; hour; the treated magnetic beads were taken out with a magnetic bar, washed with n-he...

Embodiment 3

[0137] Example 3: Preparation of block copolymer of divinylbenzene and pyrrolidone with magnetic mesoporous

[0138] Add 200 milliliters of pure water and 1 gram of hydroxypropyl cellulose to a 1-liter reaction flask, heat to dissolve and cool to below 40°C; take 1.3 grams of LM (prepared in Example 1), 15 grams of divinylbenzene, and 10 grams of ethylene Pyrrolidone, 0.2 g of AIBN, 20 g of toluene, stir well and add to the above aqueous solution, stir the suspension to 500 rpm, gradually raise the temperature to 75°C, keep stirring and temperature for 20 hours; filter, wash with ethanol, extract with n-hexane After vacuum drying, disperse in ethanol, suck out the magnetic material with a magnetic rod, and obtain 16 grams of brown particles after vacuum drying, with a particle size of about 20-60 microns, an average pore diameter of about 5 nanometers, and a pore volume of 0.6 mL / g. The surface is 572 square meters per gram (tested by BET method), and the nitrogen content is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com