Application of magnetic molecular imprinting technique in chiral recognition of microfluidic system

A magnetic molecular imprinting and microfluidic analysis technology, applied in the application field of magnetic molecular imprinting technology, can solve the problems of no efficacy, toxic and side effects, and low enantiomeric efficacy, and achieve low cost, simple operation, and economical operation. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

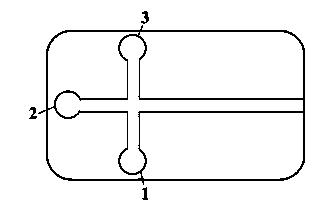

[0051] Fabrication of PDMS chip: use gallium arsenide (GaAs) positive mold (produced by Nanjing 55th Institute of Electronics) as a template to make a cross-shaped PDMS microfluidic chip channel, such as figure 1 shown. The specific production process is as follows: Take a certain amount of PDMS monomer and curing agent according to 10:1 (mass ratio), mix evenly, degas, pour on the GaAs template, and cure at 70 °C for 2 hours. After cooling, peel off the PDMS chip containing the cross-shaped channel from the template, cut it into the desired shape with a blade, and punch holes in the buffer pool, sample pool and sample waste pool with a puncher to form a diameter of 3 mm holes. At the same time, using the smooth glass plate as a template, follow the same steps to prepare a PDMS chip without microchannels as a cover slip. The PDMS chip containing the cross channel and the PDMS cover sheet without the channel were ultrasonically cleaned with secondary water, methanol, and sec...

Embodiment 2

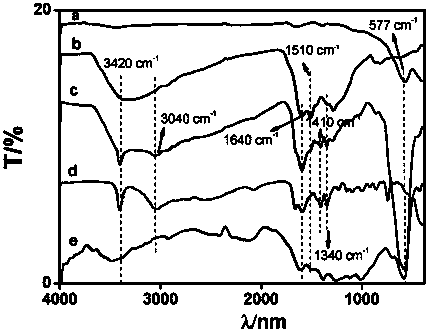

[0053] (1) Synthesis of magnetic Fe by hydrothermal method 3 o 4 Nanoparticles (NPs): 1.35 g FeCl 3 6H 2 O was dissolved in 40 mL of ethylene glycol, and ultrasonically mixed evenly; 3.6 g of anhydrous NaAc and 1.0 g of polyethylene glycol were added to the above solution, ultrasonicated for 20 min, and the mixed solution was transferred to an autoclave at 180 ° C reaction for 6 h, after the autoclave was cooled to room temperature, the product was washed several times with double distilled water, and dissolved in 4 mL of double distilled water to obtain Fe with a concentration of 50.2 mg / mL and an average particle size of 126 nm. 3 o 4 NPs.

[0054] (2) MIP-Fe 3 o 4 Preparation of PDA NPs magnetic molecularly imprinted polymer: 25 mg Fe 3 o 4 NPs and 50 mg of the template molecule D / L-tryptophan were dissolved in 10 mL of 20 mM PBS buffer solution with pH 8.5. After mechanical stirring and mixing, 15 mg of functional monomer dopamine was added to the above solution...

Embodiment 3

[0061] MIP-Fe 3 o 4 Immobilization of PDA NPs Magnetic Molecularly Imprinted Polymers in PDMS Microchannels

[0062] (1) The fabrication process of the PDMS microfluidic chip refers to the steps in Example 1.

[0063] (2) MIP-Fe 3 o 4 Immobilization of PDA NPs magnetic molecularly imprinted polymers in PDMS microchannels: first place a permanent magnet on the upper and lower sides of the PDMS chip microchannel (so that the mutually attracting poles correspond to each other), and the PDMS microchip channel is rinsed with double distilled water for 10 min Finally, the prepared MIP-Fe imprinted cavity with specific recognition of chiral tryptophan was prepared by vacuum pump 3 o 4 The magnetic molecularly imprinted polymer of PDA NPs was continuously pumped into the separation channel for 5 min. Under the action of an external magnetic field, the MIP-Fe 3 o 4 PDA NPs magnetic molecularly imprinted polymers were rapidly and controllably immobilized at designated positions i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com