A kind of preparation method of manganese-based Prussian white cathode material and its application in sodium-ion battery electrode

A sodium-ion battery and Prussian white technology, which is applied in the field of new energy storage batteries, can solve the problems affecting the specific capacity of reaction products, slow manganese salt solution drop rate, and low specific capacity of electrode materials, so as to achieve low cost and improve battery life. Chemical properties, effect of increasing sodium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] This embodiment discloses a method for preparing a manganese-based Prussian white cathode material, which includes the following steps:

[0027] Step 1), dissolving the manganese salt containing divalent manganese ions in deionized water to form solution A; wherein the manganese salt is selected from one or more of manganese chloride, manganese sulfate, and manganese nitrate ;

[0028] Step 2), dissolving sodium ferrocyanide in deionized water to form solution B;

[0029] Step 3), drop solution A into solution B for co-precipitation reaction to obtain a suspension solution, the dropping rate of solution A is 5mL / min~40mL / min; preferably, the dropping rate of solution A is 10mL / min~30mL / min, and the Mn in solution A 2+ With [Fe(CN) in solution B 6 ] 2- The molar ratio is 1 to 2.1;

[0030] Step 4), move the suspension solution obtained in step 3) to the reaction kettle, and add soluble sodium salt, after a certain period of hydrothermal reaction, the hydrothermal r...

Embodiment 1

[0033] Step 1) manganese sulfate is dissolved in deionized water to obtain 2+ The concentration is 500mL of the solution of 0.3mol / L, and the solution A is obtained through thorough stirring;

[0034] Step 2) dissolving sodium ferrocyanide in deionized water, stirring evenly to obtain 500 mL of B solution whose concentration in terms of ferrocyanide ion is 0.2mol / L; 2+ with [Fe(CN) 6 ] 2- The molar ratio is 1.5;

[0035] Step 3) Then use a peristaltic pump to pump solution A into solution B at a rate of 10mL / min, during which solution B is kept in a state of rapid stirring;

[0036] Step 4) Move the reacted solution into a reaction kettle, add 0.15 mol NaCl, seal it, carry out hydrothermal reaction, keep warm at 80°C for 3 hours, and after hydrothermal reaction, cool, wash and dry to obtain manganese-based Prussian white.

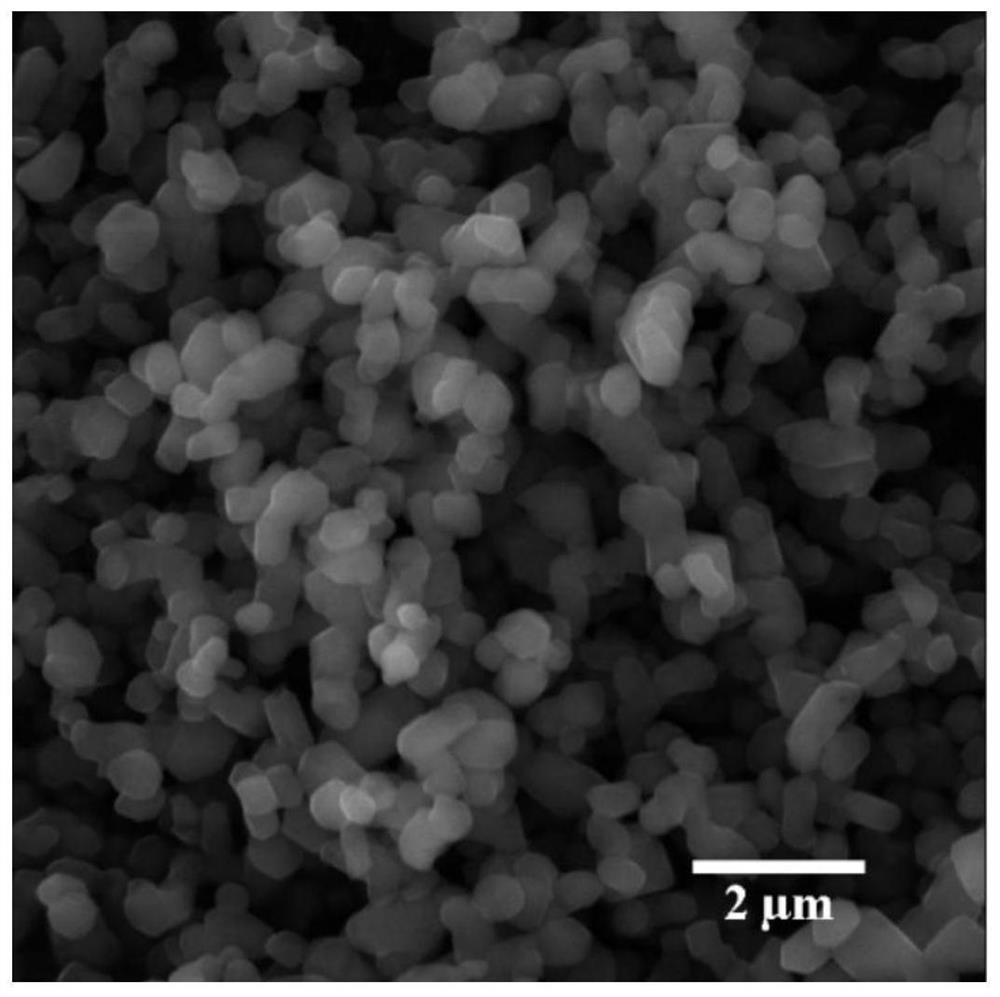

[0037] figure 1 The scanning electron micrograph of the manganese-based Prussian white prepared in Example 1 shows that the particles obtained after t...

Embodiment 2

[0039] Step 1) manganese chloride is dissolved in deionized water to obtain 2+ The concentration is 500mL of the solution of 0.3mol / L, and the solution A is obtained through thorough stirring;

[0040] Step 2) dissolving sodium ferrocyanide in deionized water, stirring evenly to obtain 500 mL of B solution whose concentration in terms of ferrocyanide ion is 0.3mol / L; 2+ with [Fe(CN) 6 ] 2- The molar ratio of is 1;

[0041] Step 3) Then use a peristaltic pump to pump solution A into solution B at a rate of 20mL / min, during which solution B is kept in a state of rapid stirring;

[0042] Step 4) the solution after the reaction moves in the reactor, and adds 0.3molNa 2 SO 4 , after sealing, carry out hydrothermal reaction, heat preservation at 90°C for 5 hours, after hydrothermal reaction, after cooling, washing and drying, manganese-based Prussian white is obtained.

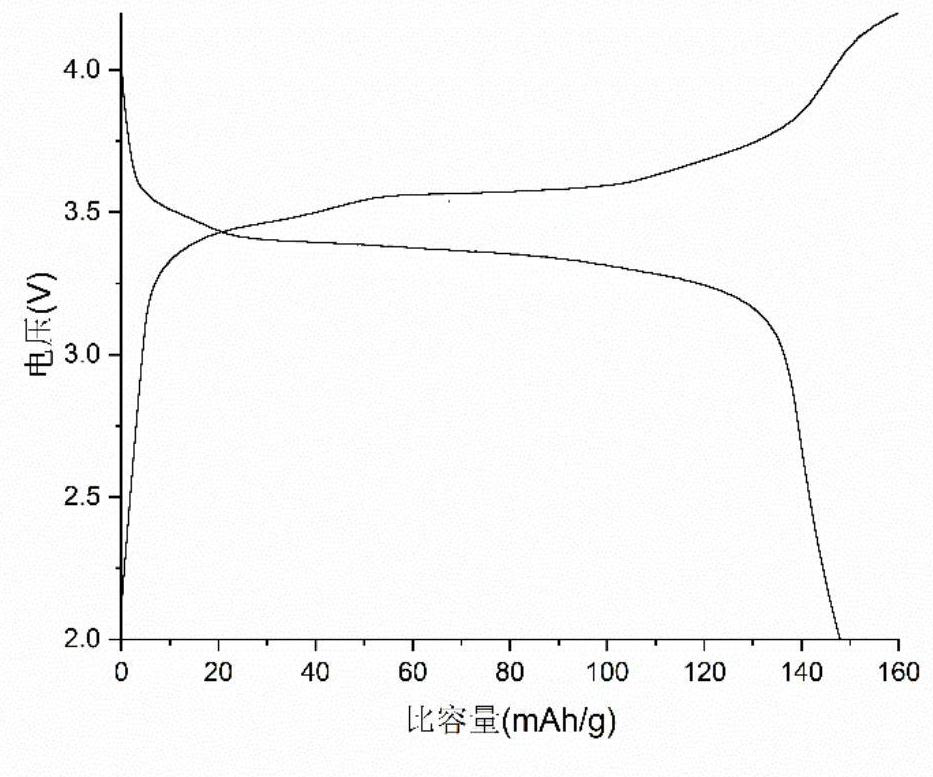

[0043]The Prussian white prepared in this example was used as the positive electrode material to make a pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com