A kind of preparation method of bacitracin impurity 1 based on photocatalysis

A bacitracin and photocatalytic technology, which is applied in the field of biochemistry, can solve the problems of low bacitracin impurity L content, unsuitable preparation method, and low preparation efficiency, and achieve the effects of simple post-processing, low cost, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

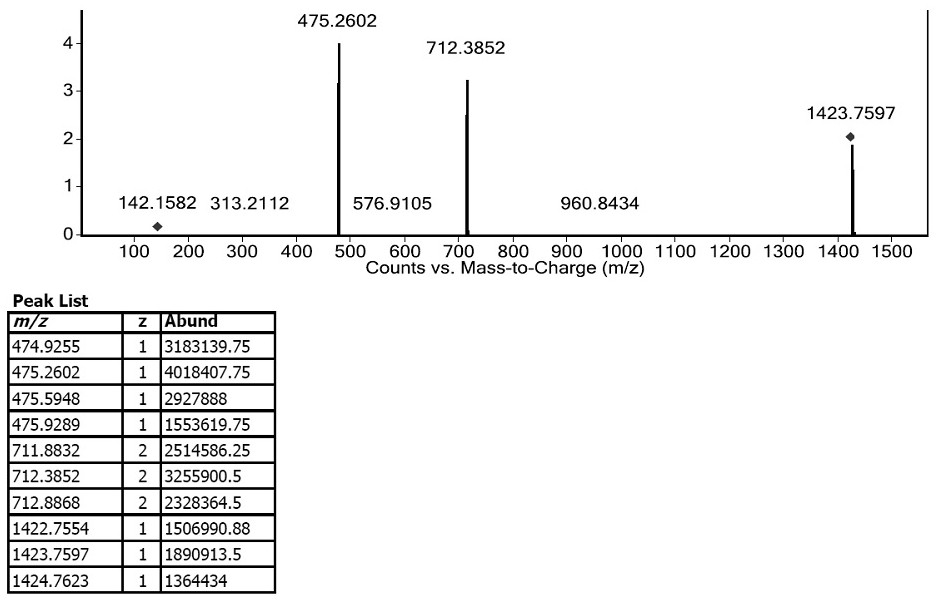

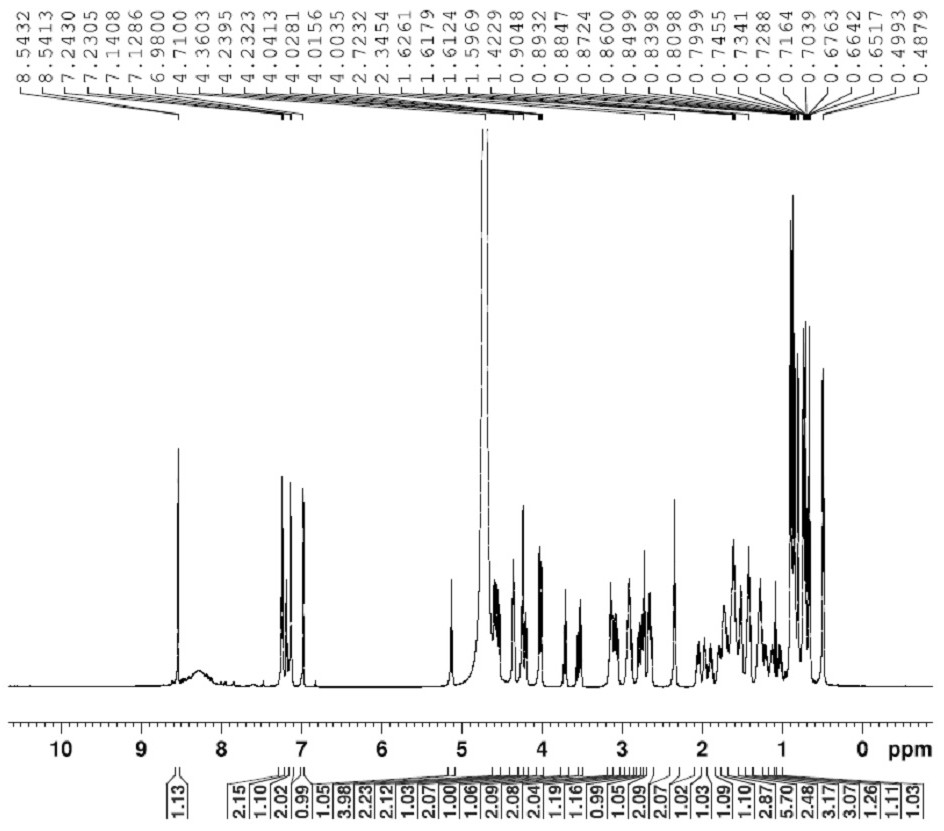

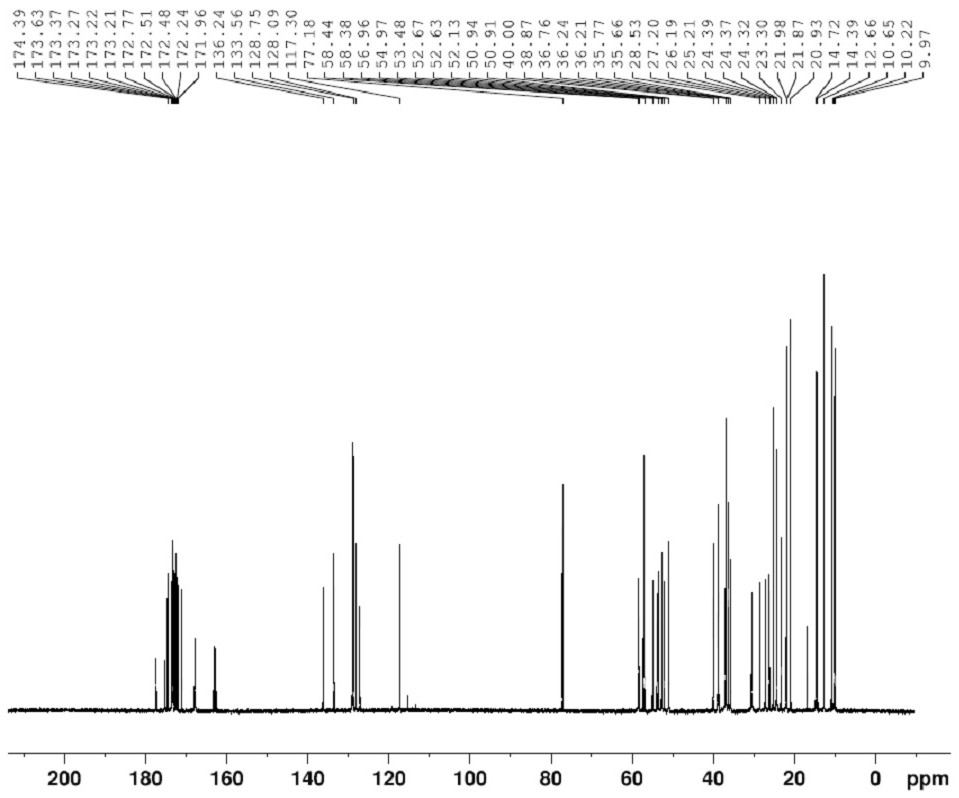

Image

Examples

Embodiment 1

[0027] Instruments: Preparative Liquid Phase (Waters 2525); Rotary Rotary Evaporator (Shanghai Yarong); Photochemical Reactor (Shanghai Julai Experimental Instrument Co., Ltd.).

[0028] Preparation of crude bacitracin impurity L: Dissolve 3 g of bacitracin raw material in 50 ml of ethanol, add 1 ml of trifluoroacetic acid to aid dissolution, and react for 2 hours at 50° C. with a light intensity of 5000 Lux in a photochemical reactor to obtain a content of impurity L of 30%. crude products. The above content is the content characterized by the HPLC area normalization method.

[0029] Preparative column: the filler is Kromasil EternityXT-10-C18, and the column tube is HB-DAC50.

[0030] Preparative liquid phase separation chromatographic conditions: carry out isocratic elution with 0.1% volume concentration trifluoroacetic acid aqueous solution-acetonitrile (70:30, V / V) as mobile phase; Flow rate is 100mL / min; Detection wavelength 254nm; Column temperature is Room temperatur...

Embodiment 2

[0046] Instruments: Preparative Liquid Phase (Waters 2525); Rotary Rotary Evaporator (Shanghai Yarong); Photochemical Reactor (Shanghai Julai Experimental Instrument Co., Ltd.).

[0047] Preparation of crude bacitracin impurity L: Dissolve 3 g of bacitracin raw material in 30 ml of methanol, add 1 ml of trifluoroacetic acid, and react at 50° C. for 3 hours in a photochemical reactor with light intensity of 4500 Lux to obtain a crude product with an impurity L content of 35%. . The above content is the content characterized by the HPLC area normalization method.

[0048] Preparative column: the filler is Kromasil EternityXT-10-C18, and the column tube is HB-DAC50.

[0049] Preparative liquid phase separation chromatographic conditions: carry out isocratic elution with 0.1% volume concentration trifluoroacetic acid aqueous solution-acetonitrile (70:30, V / V) as mobile phase; Flow rate is 100mL / min; Detection wavelength 254nm; Column temperature is Room temperature; manual injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com