Milk-flavored soft ice cream slurry and preparation method thereof

A soft ice cream, milk-flavored technology, applied in the direction of frozen desserts, food ingredients containing natural extracts, functions of food ingredients, etc., can solve the problems of digestion and absorption system obstruction, sensory quality impact, poor product stability, etc. The effect of digestion and absorption, enhancing appetite, and accelerating metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

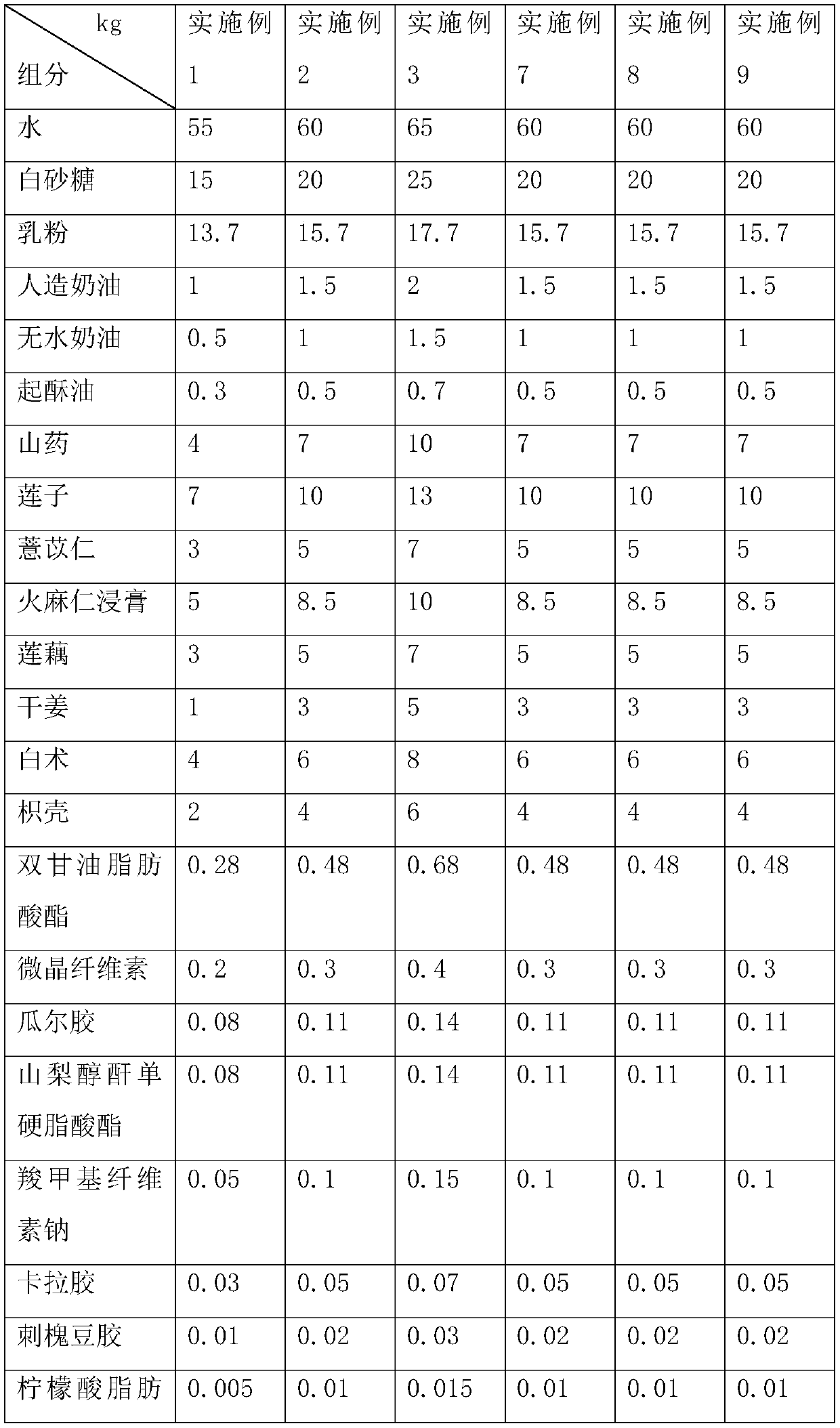

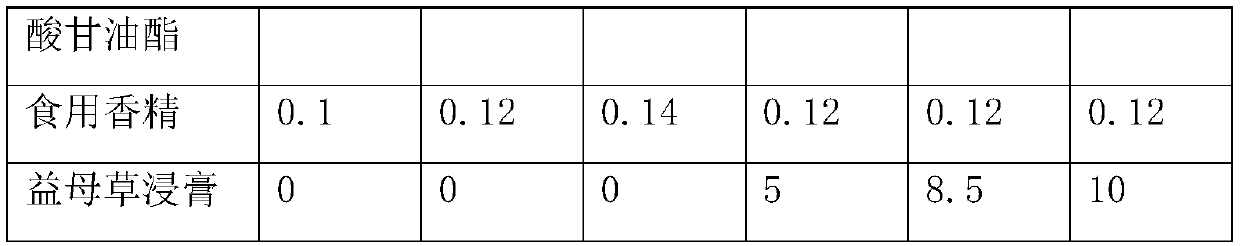

Examples

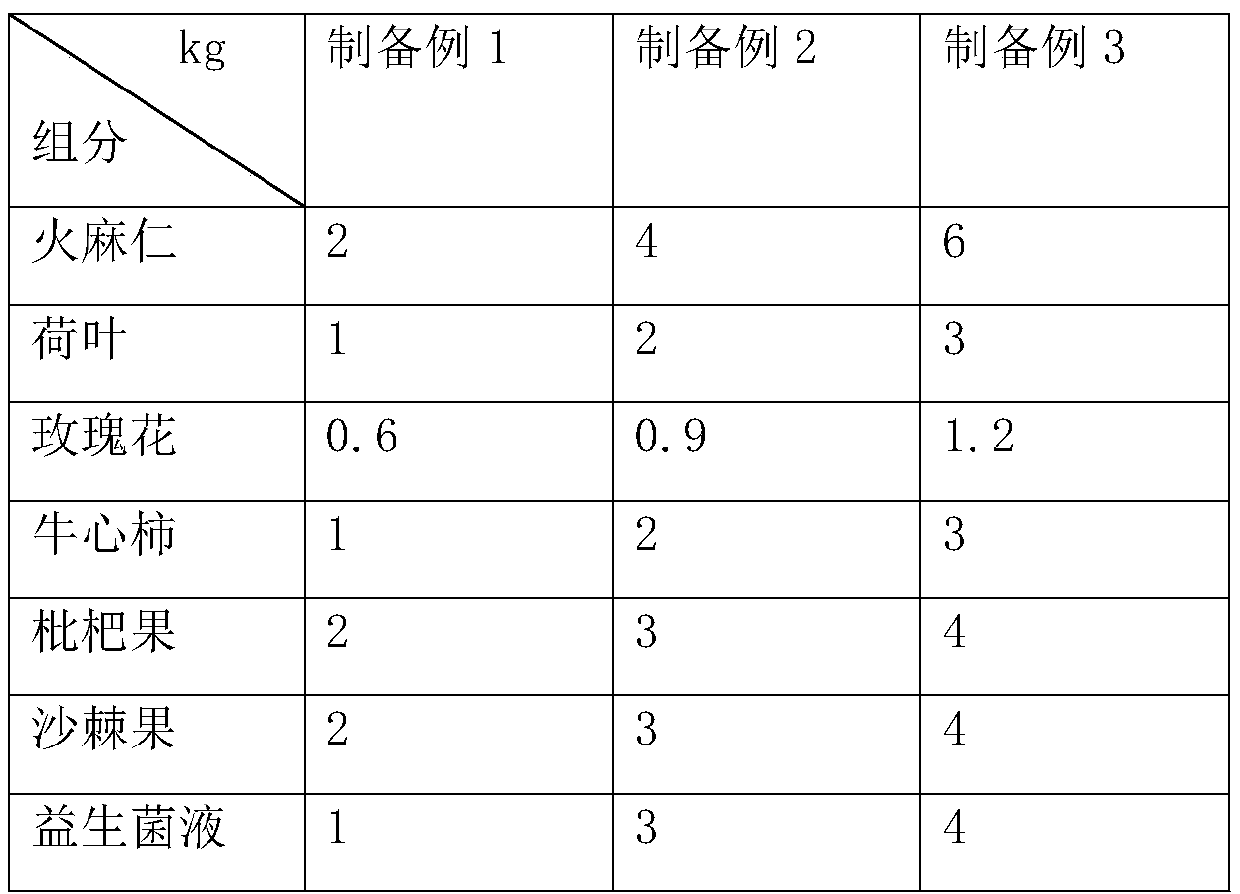

preparation example 1-3

[0047] Preparation example 1: (1) According to the proportioning in Table 1, after shelling 2kg of hemp seeds, mix with dried 1kg of lotus leaves and 0.6kg of roses, add 40% ethanol, soak for 24h, extract and reflux , filter through a 200-mesh sieve to remove slag, collect the primary extract and raw material slag, the mass ratio of ethanol to hemp seed is 10:1, the leaching reflux temperature is 80°C, and the leaching reflux time is 1.5h;

[0048] (2) adding concentration is 40% ethanol in raw material slag, leaching refluxes, collects secondary extract, merges primary extract and secondary extract, distills and recovers ethanol, makes concentrated solution, raw material slag and The mass ratio of ethanol is 1:8, the leaching reflux temperature is 80°C, and the leaching reflux time is 1h;

[0049] (3) Peel and remove 1kg of persimmon, 2kg of loquat fruit and 2kg of seabuckthorn fruit, crush them into pulp, add concentrated solution and 1kg of probiotic solution with a concent...

preparation example 2

[0052] Preparation Example 2: (1) According to the proportioning in Table 1, after shelling 4kg of hemp seeds, mix with dried 2kg of lotus leaves and 0.9kg of roses, add 50% ethanol, soak for 22h, extract and reflux , filter through 200 mesh sieve to remove slag, collect primary extract and raw material slag, the mass ratio of ethanol and hemp seed is 13:1, the leaching reflux temperature is 90°C, and the leaching reflux time is 1h;

[0053] (2) adding concentration to raw material slag is the ethanol of 50%, leaching reflux, collects secondary extraction liquid, merges primary extraction liquid and secondary extraction liquid, distillation reclaims ethanol, makes concentrated solution, raw material residue and The mass ratio of ethanol is 1:9, the leaching reflux temperature is 90°C, and the leaching reflux time is 0.5h;

[0054] (3) Peel and remove the core of 2kg of persimmon, 3kg of loquat fruit and 3kg of seabuckthorn fruit, crush them into pulp, add the concentrated solu...

preparation example 3

[0055] Preparation Example 3: (1) According to the proportioning in Table 1, after shelling 6 kg of hemp seeds, mix with dried 3 kg of lotus leaves and 1.2 kg of roses, add 60% ethanol, soak for 20 hours, extract and reflux , filter through a 200-mesh sieve to remove slag, collect the primary extract and raw material slag, the mass ratio of ethanol to hemp seed is 15:1, the leaching reflux temperature is 100°C, and the leaching reflux time is 0.5h;

[0056] (2) Adding concentration to the raw material slag is 60% ethanol, leaching reflux, collecting the secondary leaching solution, merging the initial leaching solution and the secondary leaching solution, distillation and recovery of ethanol, making concentrated solution, raw material slag and The mass ratio of ethanol is 1:10, the leaching reflux temperature is 100°C, and the leaching reflux time is 0.1h;

[0057] (3) Peel and remove 3kg of persimmon, 4kg of loquat fruit and 4kg of sea-buckthorn fruit, crush them into pulp, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com