A complex iron desulfurizer

A technology of desulfurization agent and complex iron, which is applied in the field of desulfurization, can solve the problems of slow regeneration of desulfurization rich liquid, reduction of ferric iron content, high amount of auxiliary salts, etc. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

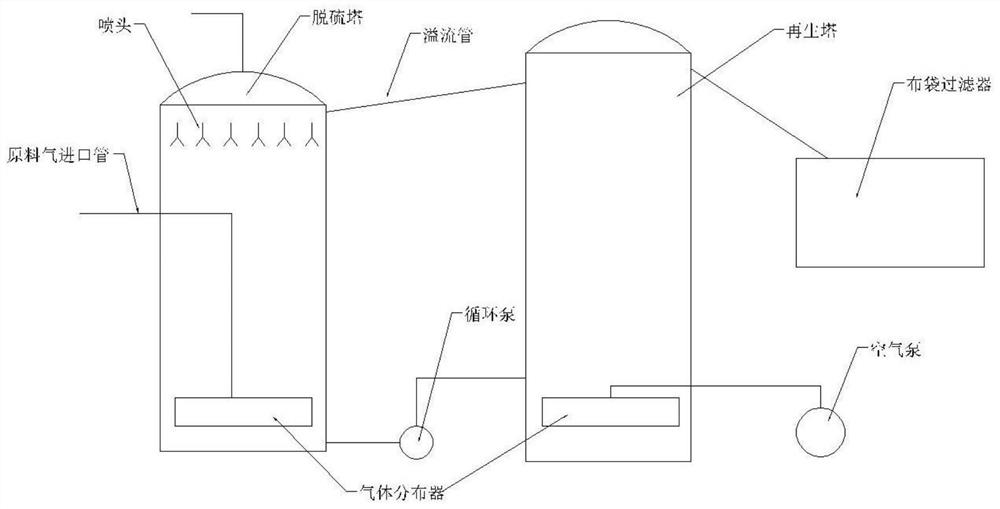

Method used

Image

Examples

Embodiment 1

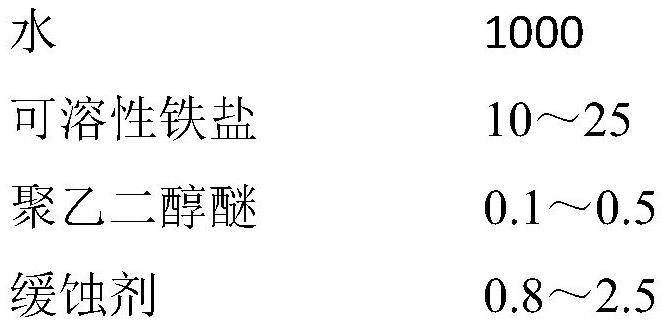

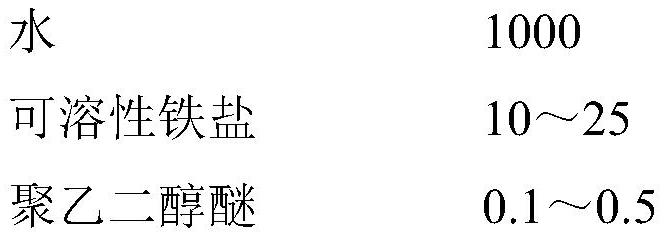

[0024] Take 1L of water, add 16.2g tetrasodium iminodisuccinate and 25.1g sodium citrate, stir well to dissolve, then add 20.0g iron sulfate, stir, when it dissolves, add 0.88g copper sulfate pentahydrate, 1.1g Sodium antimonate and 0.4 g of polyethylene glycol ether were stirred to dissolve completely, and sodium hydroxide was added to adjust the pH of the solution to 8.5 to obtain desulfurizer A.

Embodiment 2

[0026] Take 1L of water, add 24.3g tetrasodium iminodisuccinate and 37.6g sodium citrate, stir well to dissolve, then add 40.5g ferric chloride hexahydrate, stir, when it dissolves, add 0.85g copper chloride, 1.5g of sodium molybdate and 0.4g of polyethylene glycol ether were stirred to dissolve completely, and sodium carbonate was added to adjust the pH of the solution to 9 to obtain desulfurizer B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com