Series of inorganic antibacterial mildew-proof monatomic catalysts and preparation method thereof

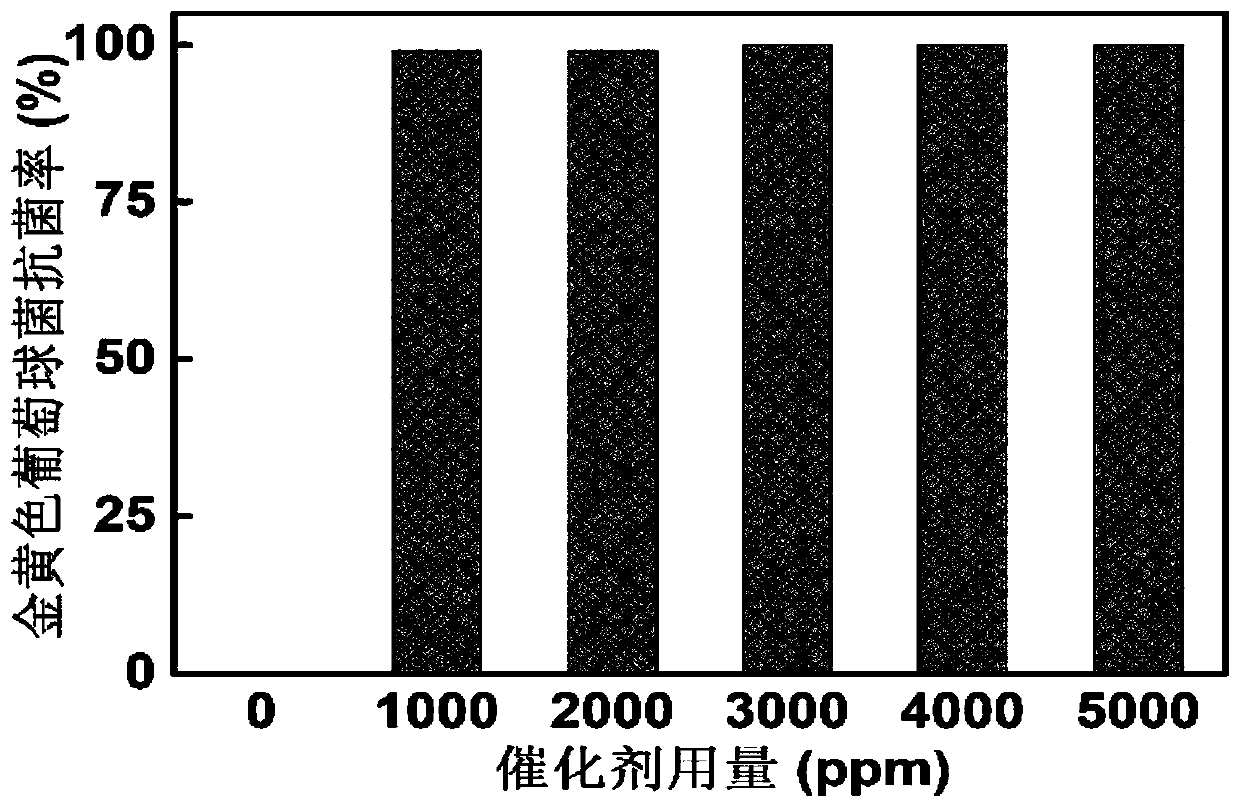

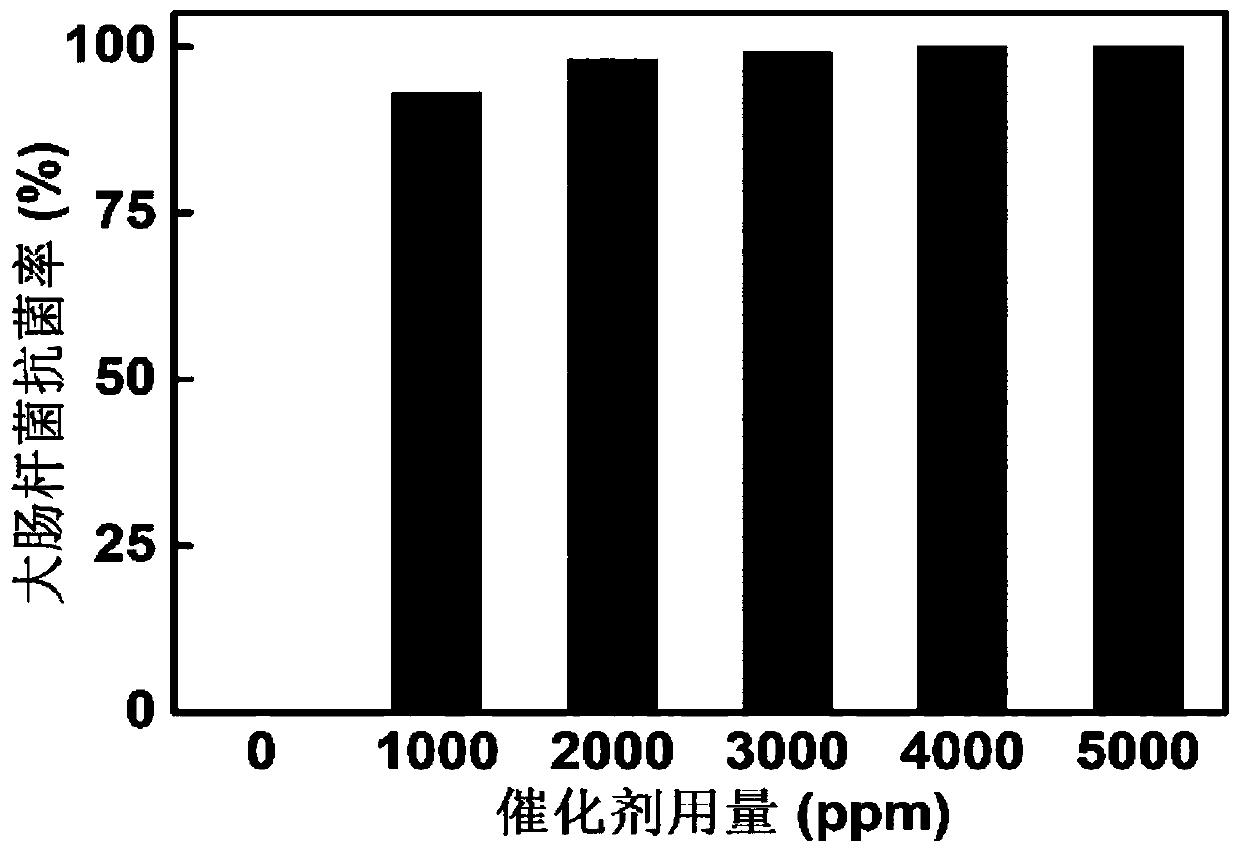

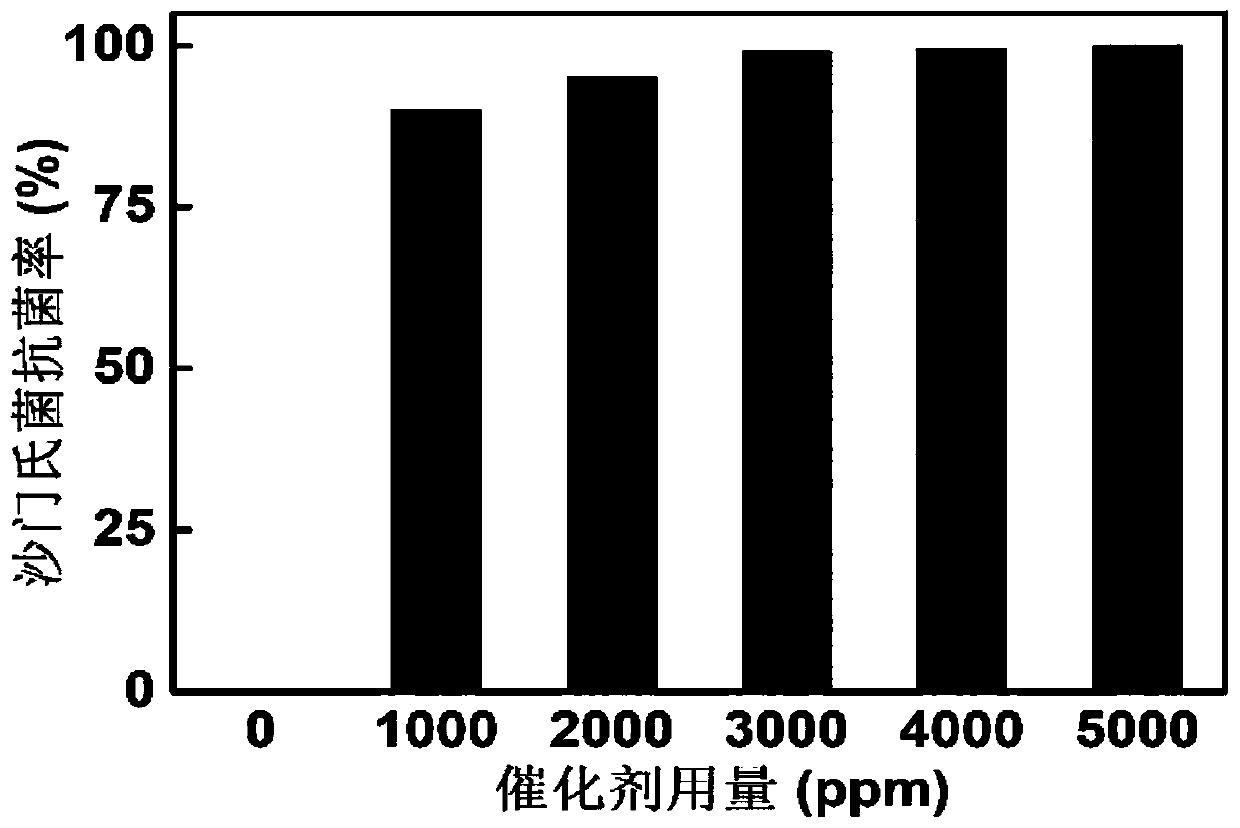

An inorganic antibacterial, antibacterial and antifungal technology, which is applied in the field of inorganic antibacterial and antifungal single-atom catalysts and its preparation, can solve the problems such as difficulty in meeting the requirements of antibacterial and antifungal applications, and achieve the effects of excellent antibacterial performance and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1, adding an aqueous solution of 5g / L ferric chloride into diatomite (inorganic silicon-based carrier), wherein the mass ratio of transition metal to carrier is 1:20, and the resulting solution is dispersed evenly by ultrasonication for 30min under the condition of 100kHz, and then Stir the mixed solution at 100r / min for 12h;

[0028] Step 2, warming up the mixed solution obtained in step 1 to the boiling point of water, volatilizing at high temperature, evaporating the solvent, and fully grinding for 0.5 hours with a ball mill at a speed of 50 r / min to obtain a solid powder;

[0029] Step 3: heat the solid powder obtained in step 2 for 2 hours in an air atmosphere and at a temperature of 400° C., cool to room temperature, and grind in a ball mill for 20 minutes at a speed of 50 r / min to obtain the desired catalyst. The prepared catalyst The contained transition metals are anchored to the defect sites on the surface of the support in the form of single atoms.

Embodiment 2

[0031] Step 1, the aqueous solution of 10g / L cupric chloride is added in the calcium carbonate (inorganic calcium-based carrier), wherein the mass ratio of transition metal and carrier is 1:50, ultrasonic 30min is dispersed evenly under the condition of the gained solution 100kHz, and then The mixed solution was stirred at 150r / min for 20h;

[0032] Step 2, heating the mixed solution obtained in step 1 to the boiling point of water, volatilizing at high temperature, evaporating the solvent to dryness, and fully grinding for 1 hour with a ball mill at a speed of 100 r / min to obtain a solid powder;

[0033] Step 3, heat the solid powder obtained in step 2 for 3 hours in an air atmosphere and at a temperature of 200°C, cool to room temperature, and grind the ball mill for 30 minutes at a speed of 100r / min to obtain the desired catalyst. The prepared catalyst The contained transition metals are anchored to the defect sites on the surface of the support in the form of single atoms....

Embodiment 3

[0035] Step 1, add 200g / L cobalt chloride in water and ethanol (volume ratio is 1:1) solution to alumina (inorganic aluminum-based carrier), wherein the mass ratio of transition metal to carrier is 1:200, and the resulting solution is 100kHz Ultrasonic 30min under the condition of uniform dispersion, and then the mixed solution was stirred at 200r / min for 48h;

[0036] In step 2, the mixed solution obtained in step 1 is heated to the boiling point of the mixed solution, evaporated at high temperature, evaporated to dryness, and fully ground for 3 hours with a ball mill at a speed of 500 r / min to obtain a solid powder;

[0037] Step 3: Heat the solid powder obtained in Step 2 for 4 hours under an argon atmosphere and a temperature of 800° C., cool to room temperature, and grind for 40 minutes in a ball mill at a speed of 500 r / min to obtain the desired catalyst. The prepared The transition metals contained in the catalyst are anchored on the defect sites on the surface of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com