Anti-freezing asphalt mixture and preparation method thereof

An asphalt mixture and anti-icing technology, which is applied in the field of pavement materials, can solve the problems of reduced durability of anti-icing on the road surface, affecting the smooth driving safety of the road, and reducing the anti-skid performance of the road surface, so as to reduce the freezing point and improve the anti-icing performance. Water damage performance, good anti-icing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

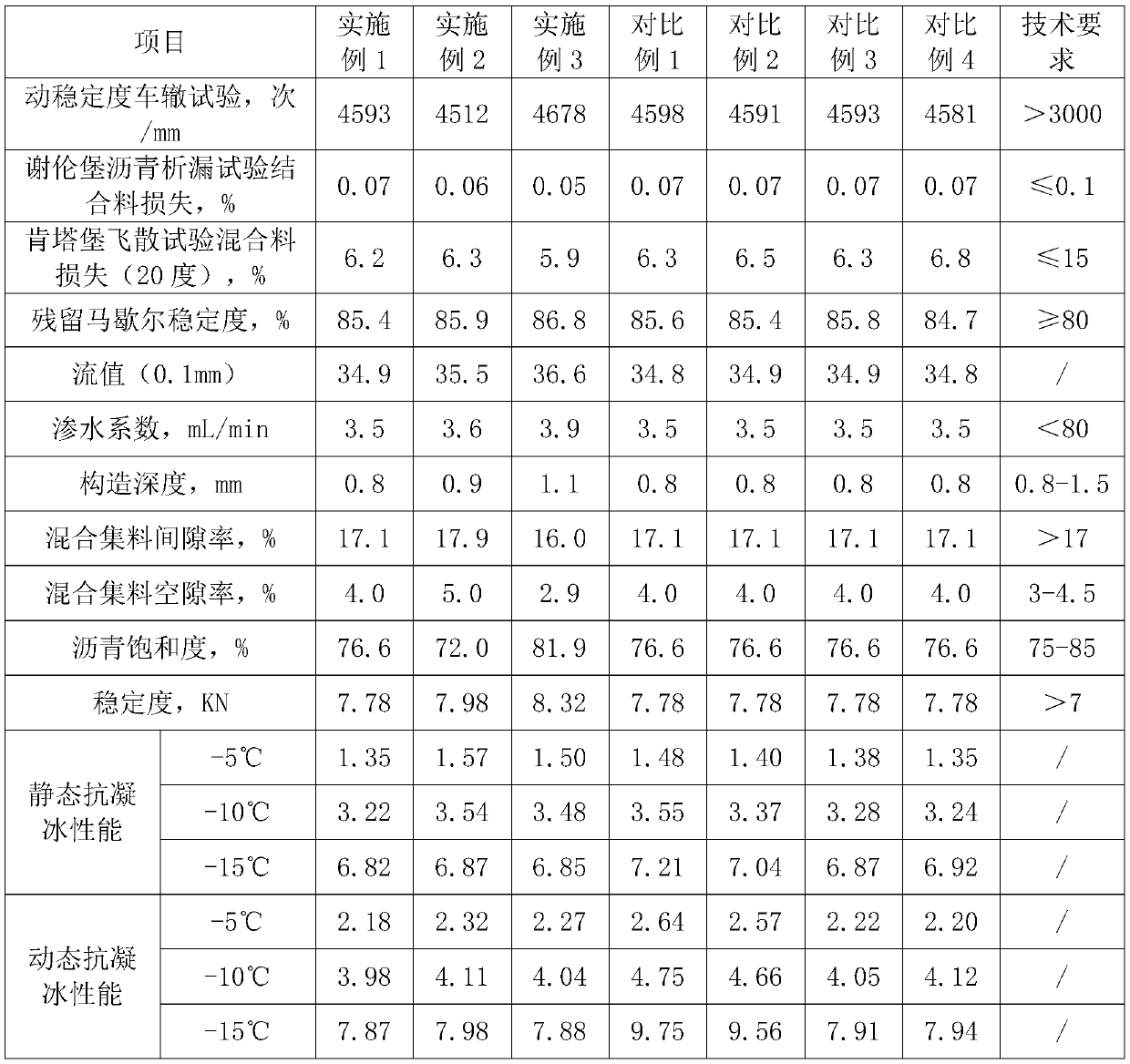

Examples

preparation example Construction

[0037]Preparation example of anti-icing agent The mesoporous molecular sieve SBA-15 in the following preparation example is provided by Shanghai Juna Technology Co., Ltd.; sodium polyacrylate is provided by Henan Ruilunte Biotechnology Co., Ltd.; polyvinyl acetate is provided by Wacker, Germany The model is polyvinyl acetate UW10 FS; the polyvinyl alcohol is selected from the polyvinyl alcohol of the model PVA-205 provided by Japan Kuraray; the sodium carboxymethyl cellulose is selected from the model FH6 provided by Zhengzhou Xuxin Chemical Co., Ltd. sodium carboxymethylcellulose.

[0038] Preparation example 1 of anti-icing agent: ① Take 37kg sodium chloride and 100kg water, heat and stir to 50°C, prepare a saturated solution of sodium chloride, heat it to 50°C, add 30wt% hydrochloric acid to adjust its pH to 1 , obtain acidic sodium chloride solution; get 18.6kg calcium chloride and 25kg water, stir at normal temperature, obtain the saturated solution of calcium chloride; ...

preparation example 2

[0045] Preparation example 2 of anti-icing agent: ① Take 37kg sodium chloride and 100kg water, heat and stir to 50°C, prepare a saturated solution of sodium chloride, heat it to 50°C, add 30wt% hydrochloric acid to adjust its pH to 1 , obtain acidic sodium chloride solution; get 18.6kg calcium chloride and 25kg water, stir at normal temperature, obtain the saturated solution of calcium chloride;

[0046] ②Take 9kg of zeolite powder, 2.5kg of maleic anhydride, 1.5kg of sodium polyacrylate and 200kg of absolute ethanol, and disperse by ultrasonic vibration for 25min to obtain an ethanol suspension of modified zeolite powder;

[0047] ③ Within 1.5 hours, add the acidic sodium chloride solution dropwise to the ethanol suspension of the modified zeolite powder. Sodium-zeolite complex;

[0048] ④ Take the saturated solution of calcium chloride, add 0.6kg mesoporous molecular sieve SBA-15, after stirring for 15 minutes, keep the temperature for 60 minutes, and filter under reduced p...

preparation example 5

[0063] Preparation example 5 of anti-icing agent: 1. get 18.6kg calcium chloride and 25kg water, stir at normal temperature, obtain the saturated solution of calcium chloride;

[0064] ② Take the saturated solution of calcium chloride, add 0.5kg of mesoporous molecular sieve SBA-15, stir for 10 minutes, keep the temperature for 50 minutes, and filter under reduced pressure to obtain the calcium chloride-SBA-15 complex;

[0065] ③Take 200kg of water, heat it to 95°C, then add 30kg of polyvinyl acetate, 10kg of polyvinyl alcohol, and 8kg of sodium carboxymethylcellulose, and stir evenly to obtain a coating solution;

[0066] ④ Spray the coating liquid on the inorganic salt complex, dry at 120°C for 8 hours, and form a coating film with a thickness of 50 μm on the surface of the inorganic complex to obtain an anti-icing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com