Highly graphitized boron-doped carbon nanocapsule and preparation method thereof

A technology of nanocapsules and boron doping, which is applied in the field of nanomaterials, can solve the problems of high cost, and achieve the effects of low cost, important practical value, and simple method operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

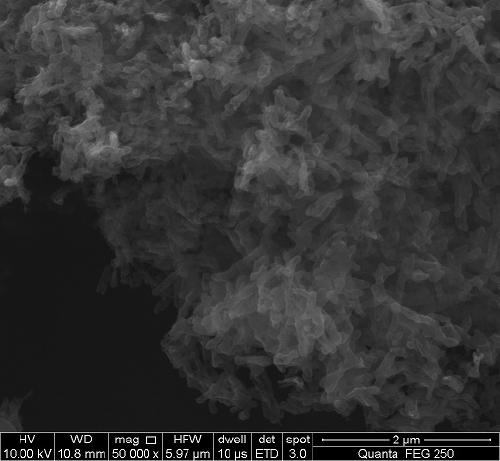

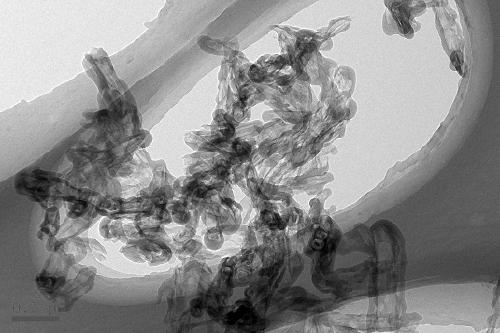

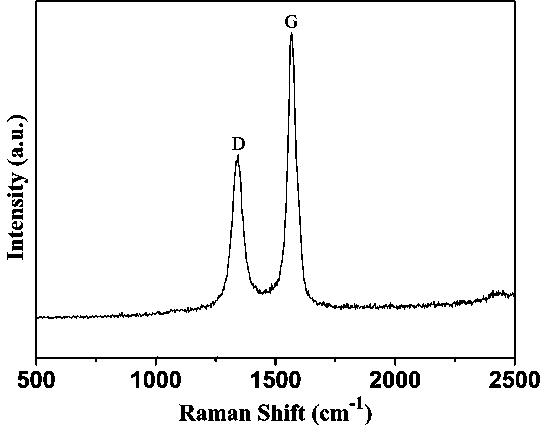

[0037] A preparation method of highly graphitized boron-doped carbon nanocapsules, the steps are as follows:

[0038] Accurately weigh 0.8g of halloysite and 8g of glucose, add alcohol (the mass fraction of alcohol is 99.5%) and 160mL of water with a volume ratio of 1:1, put them into a beaker, ultrasonicate for 30min, and stir on a magnetic stirrer for 2h , and then put it into a 200mL hydrothermal reaction kettle, and heat it at 180°C for 8h. The obtained hydrothermal product was filtered and washed with a water-alcohol mixture with a volume ratio of 5:1, and then dried in a vacuum oven at 50°C for 24 hours. The obtained dried product was placed in 15% HF and H at a volume ratio of 1:1. 2 SO 4 Soak in the mixture for 24 hours, then filter and wash until the filtrate is neutral, and put the obtained product in a vacuum drying oven to dry at 60°C for 24 hours. Then, take 2 g of the dried product, add 4.143 g of boric acid, mix evenly, put it into a high-temperature graphiti...

Embodiment 2

[0046] A preparation method of highly graphitized boron-doped carbon nanocapsules, the steps are as follows:

[0047] Accurately weigh 0.8g of halloysite and 8g of glucose, add alcohol (the mass fraction of alcohol is 99.5%) and 160mL of water with a volume ratio of 1:1, put them into a beaker, ultrasonicate for 20min, and stir on a magnetic stirrer for 1h , and then put it into a 200mL hydrothermal reaction kettle, and heat it at 160°C for 6h. The obtained hydrothermal product was filtered and washed with a water-alcohol mixture with a volume ratio of 5:1, and then dried in a vacuum oven at 50°C for 24 hours. The obtained dried product was placed in 25% HF and H at a volume ratio of 1:1. 2 SO 4 Soak in the mixture for 12 hours, then filter and wash until the filtrate is neutral, and put the obtained product in a vacuum drying oven for 24 hours at 50°C. Then, take 2 g of dry product, add 2 g of boric acid, mix evenly, put it into a high-temperature graphitization furnace, f...

Embodiment 3

[0049] A preparation method of highly graphitized boron-doped carbon nanocapsules, the steps are as follows:

[0050] Accurately weigh 0.8g of halloysite and 12g of glucose, add alcohol (the mass fraction of alcohol is 99.5%) and 170mL of water with a volume ratio of 1:1, put them into a beaker, ultrasonicate for 40min, and stir on a magnetic stirrer for 2h , and then put it into a 200mL hydrothermal reaction kettle, and heat it at 180°C for 8h. The obtained hydrothermal product was filtered and washed with a water-alcohol mixture with a volume ratio of 5:1, and then dried in a vacuum oven at 60°C for 24 hours. The obtained dry product was placed in 10% HF and H at a volume ratio of 1:1. 2 SO 4 Soak in the mixture for 24 hours, then filter and wash until the filtrate is neutral, and put the obtained product in a vacuum drying oven to dry at 60°C for 24 hours. Then, take 2 g of the dry product, add 8 g of boric acid, mix well, put it into a high-temperature graphitization fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of graphitization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com