Oleophylic super-hydrophobic porous aromatic framework material as well as preparation method and application thereof

A porous aromatic skeleton, super-hydrophobic technology, applied in separation methods, chemical instruments and methods, textiles and papermaking, etc., can solve the problems of low absorption rate, high process requirements, poor selectivity, etc. The effect of high, wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0047] Example 2 Synthesis of lipophilic superhydrophobic porous aromatic framework material LNU-26

[0048] (1) The synthetic route is as follows:

[0049]

[0050] (2) The preparation method is as follows:

[0051] 1. Synthesis of Samples

[0052] Put 151mg of 1,3,5-triethynylbenzene (0.998mmoL) and 549mg of 2,7-dibromo-9,10-phenanthrenequinone (1.498mmoL) into a 100mL round bottom flask, add 10mg of cuprous iodide and 30 mg of tetrakis(triphenylphosphine) palladium, carry out three gas replacement processes, make the whole system full of nitrogen, then add 20 mL of N,N'-dimethylformamide and 8 mL of triethylamine solvent to the reaction vessel by injection , the reaction was carried out at a temperature of 80° C. for 72 hours.

[0053] 2. Sample post-processing

[0054] After the reaction, the crude product was cooled to room temperature, washed repeatedly with tetrahydrofuran, ethanol and acetone, and then Soxhlet extracted with tetrahydrofuran, chloroform and methy...

Embodiment 3

[0055] Example 3 Synthesis of lipophilic superhydrophobic porous aromatic framework material LNU-27

[0056] (1) The synthetic route is as follows:

[0057]

[0058] (2) The preparation method is as follows:

[0059] 1. Synthesis of Samples

[0060] Put 151mg of 1,3,5-triethynylbenzene (0.998mmoL) and 549mg of 2,6-dibromoanthraquinone (1.498mmoL) into a 100mL round bottom flask, add 10mg of cuprous iodide and 30mg of tetra(tri After phenylphosphine) palladium, three gas replacement processes were carried out to make the whole system full of nitrogen, and then 20mL N,N'-dimethylformamide and 8mL triethylamine solvent were added to the reaction vessel by injection, and the reaction was carried out at 80°C The reaction was carried out at high temperature for 72 hours to obtain a crude product.

[0061] 2. Sample post-processing

[0062] After the reaction, the crude product was cooled to room temperature, washed repeatedly with chloroform and dichloromethane, and then Soxh...

Embodiment 4

[0063] Example 4 Detection of lipophilic superhydrophobic porous aromatic framework material

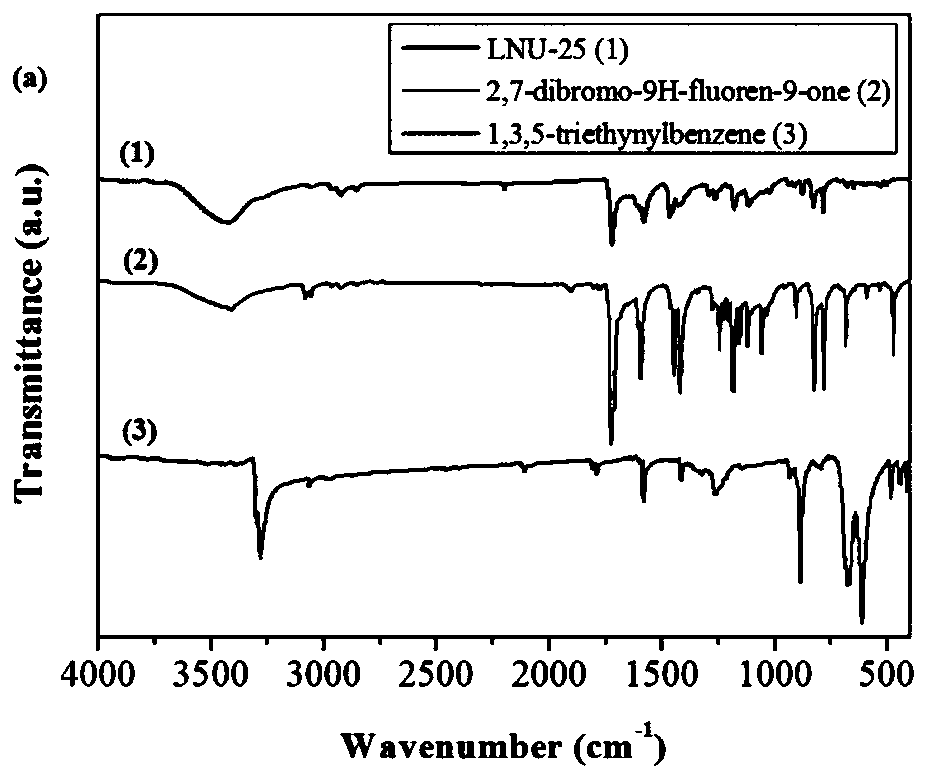

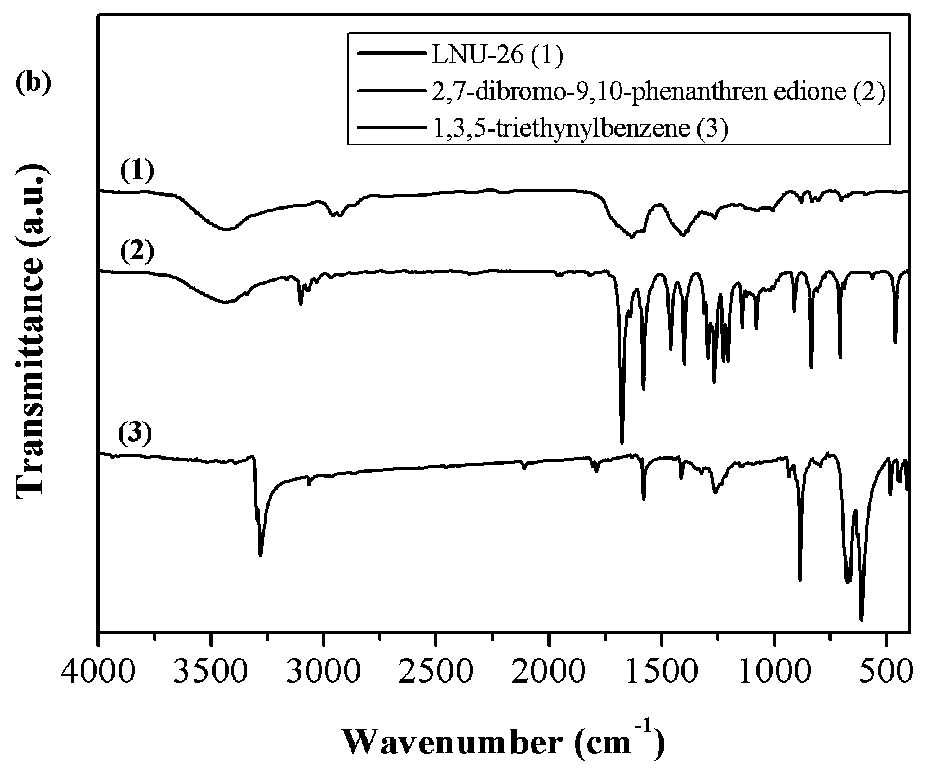

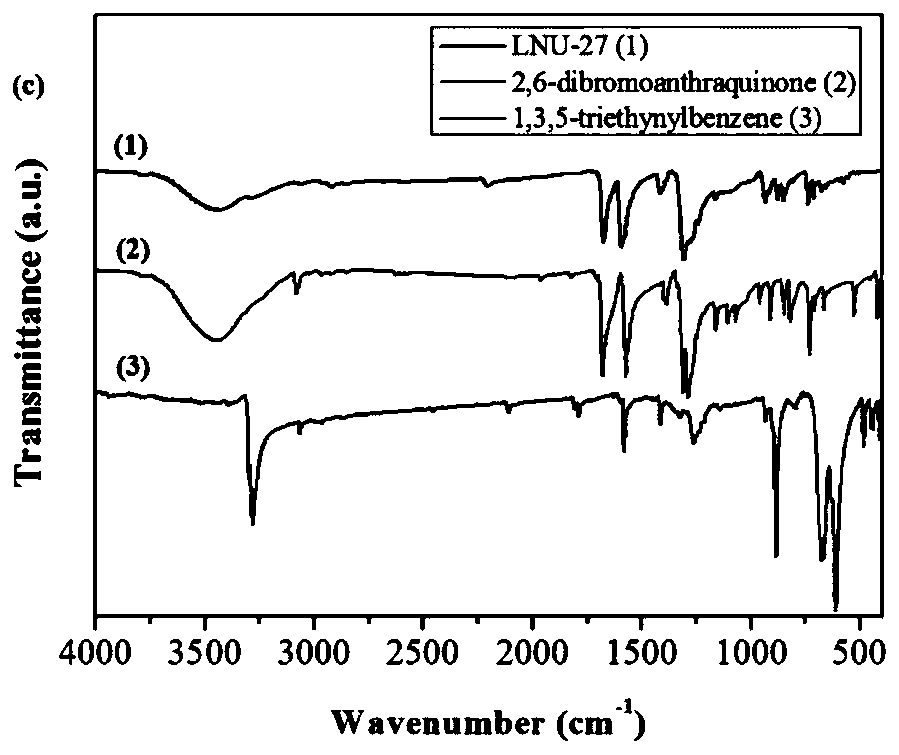

[0064] Figure 1-1 to Figure 1-3 , is the lipophilic superhydrophobic porous aromatic skeleton material LNU-25 (a) prepared by embodiment 1, embodiment 2, embodiment 3, LNU-26 (b) and LNU-27 (c) and corresponding monomer thereof Infrared spectra. It can be seen from the figure that the characteristic absorption of the reaction monomer 2,7-dibromo-9-fluorenone, 2,7-dibromo-9,10-phenanthrenequinone and 2,6-dibromoanthraquinone C-Br bond Peak (495cm -1 ) disappears in the product to prove the cleavage of the C-Br bond in the monomer; the C-H bond at the end of the monomer alkynyl group (3300cm -1 ) disappears in the polymer; near 2200cm in the infrared spectrum of the final product -1 The characteristic absorption peak of the alkynyl group -C≡C- can be seen, and the above results prove the success of the polymerization reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com