Tensile strain sensor and preparation method and application thereof

A tensile strain sensor technology, applied in the field of sensors, can solve the problems of only 65% stretching range, low sensitivity, and small stretching range, and achieve the effects of high sensitivity, wide strain range, and large measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

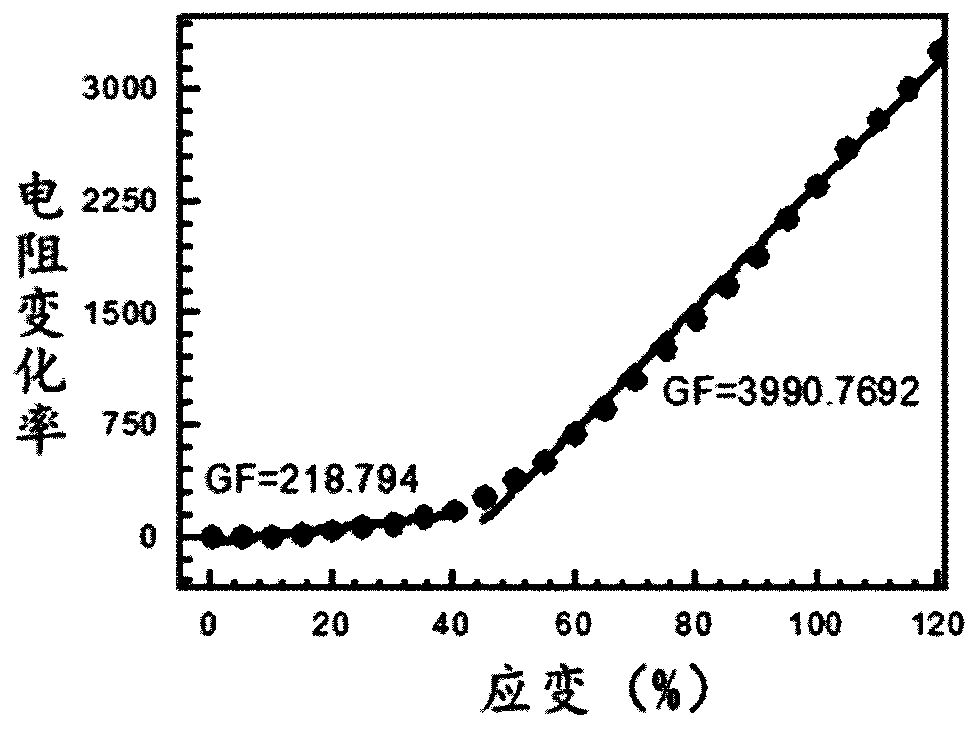

[0037] A stretchable strain sensor is obtained through a preparation method comprising the following steps, and the stretchable strain sensor has high sensitivity, high stretchability and wide strain range, as well as good stability and durability.

[0038] 1) Place a hollow polymer mask with a design pattern on the glass substrate (the design pattern is a square of 5cm*5cm);

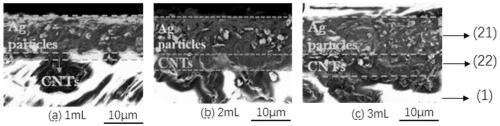

[0039] 2) Deposit 1 mL of an ethanol solution with a concentration of 0.03 g / mL silver nanoparticles on a glass substrate containing a design pattern by the drop method, and then dry at 80 °C for 5 minutes to remove ethanol to provide a layer covered with conductive metal particles (silver nanoparticles). particle) base material, the mass per unit area of conductive metal particles used in the preparation is 1.2mg / cm2 , the thickness of the conductive metal particles in the substrate covered with the conductive metal particles is about 10 microns;

[0040] 3) Spray 2 mL of the CNT dispersion with a co...

Embodiment 2

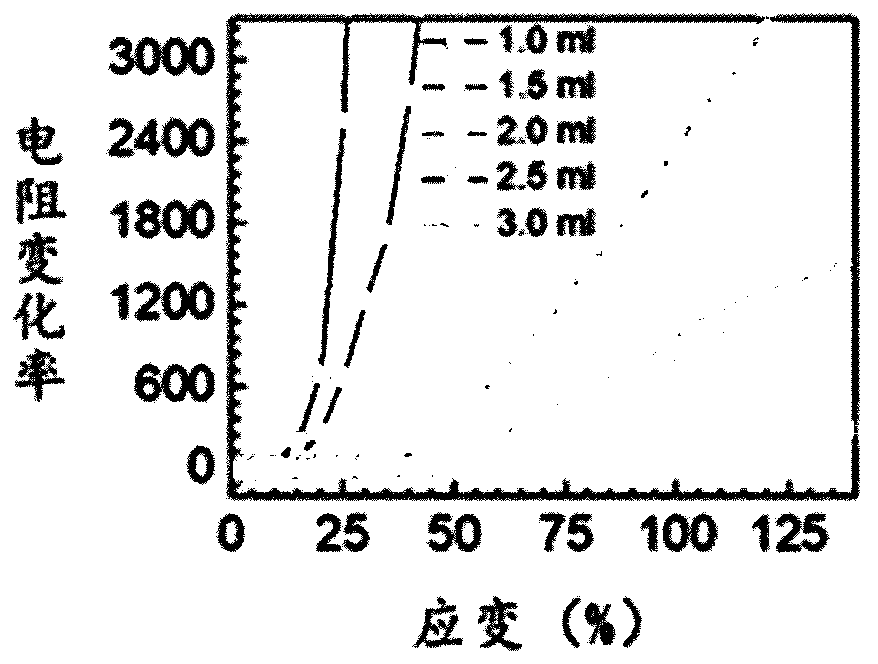

[0046] When measuring small strains, the strain sensor does not need a wide strain measurement range, and can appropriately reduce the volume consumption of the conductive carbon material, that is, reduce the thickness of the conductive carbon material layer. Example 2 uses a conductive metal particle dispersion with a concentration of 0.03 g / mL and a volume of 1 mL, that is, the mass per unit area of the conductive metal particles used in the preparation is 1.2 mg / cm 2 . The concentration of the conductive carbon material dispersion is 5mg / mL, and the volume is 1mL, that is, the mass per unit area of the conductive metal particles used in the preparation is 0.2mg / cm 2 . Other preparation steps and preparation conditions are the same as in Example 1. In step 2), the thickness of the conductive metal particles in the base material covered with conductive metal particles is about 10 microns. In step 3), the conductive carbon material and conductive metal particles are cover...

Embodiment 3

[0048] When measuring a larger strain, the strain sensor needs a larger strain detection range, and the volume consumption of the conductive carbon material can be appropriately increased, that is, the thickness of the conductive carbon material in the substrate covered with the conductive carbon material and conductive metal particles can be increased. Example 3 uses a conductive metal particle dispersion with a concentration of 0.03 g / mL and a volume of 1 mL, that is, the mass per unit area of the conductive metal particles used in the preparation is 1.2 mg / cm 2 . The volume of the conductive carbon material dispersion is 3mL, the concentration is 5mg / mL, that is, the mass per unit area of the conductive metal particles used in the preparation is 0.6mg / cm 2 . Other preparation steps and preparation conditions are the same as in Example 1. In step 2), the thickness of the conductive metal particles in the base material covered with conductive metal particles is about 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com