Modified sepiolite adsorbent, preparation method and application thereof

A sepiolite and adsorbent technology, applied in the field of modified sepiolite adsorbent, can solve problems such as harm to aquatic organisms and human health, long residual time, mutagenicity, etc., and achieve stable adsorption efficiency, large adsorption capacity, good adsorption The effect of the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

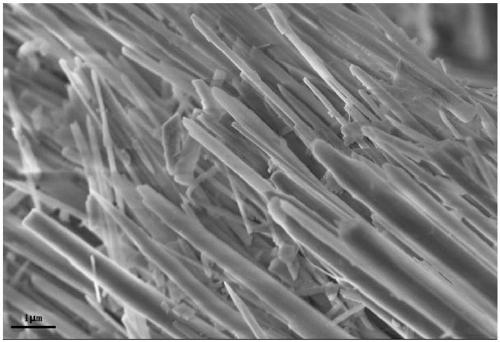

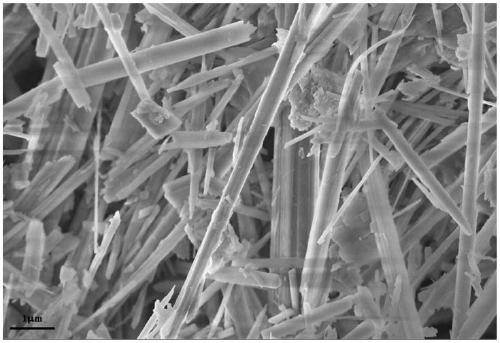

[0018] As mentioned above, in view of the deficiencies in the prior art, the inventor of this case proposed the technical solution of the present invention after long-term research and extensive practice, which mainly provides a modified sepiolite adsorbent for rapidly purifying dye wastewater The preparation method comprises: using sepiolite as a raw material, sequentially washing the sepiolite with water and high-temperature treatment in different atmospheres to obtain modified sepiolite adsorbents roasted in different atmospheres.

[0019] The technical solution, its implementation process and principle will be further explained as follows.

[0020] One aspect of the embodiments of the present invention provides a method for preparing a modified sepiolite adsorbent for rapid purification of dye wastewater, comprising:

[0021] The sepiolite powder is subjected to high-temperature treatment in a selected atmosphere to obtain a modified sepiolite adsorbent; the temperature of...

Embodiment 1

[0047] (1) Washing treatment: take commercial sepiolite, and use 500mL deionized water to carry out suction filtration and washing for several times at room temperature to remove dust impurities; remove moisture;

[0048] (2) High temperature treatment: take the sepiolite powder, add it into a quartz tube, and heat it at 100mLmin -1 The flow continues to flow into N 2 , from room temperature to 5°C min -1 The heating rate was raised to 800 ° C for 1 h, the total time of the high-temperature reaction was 10 h, and then cooled to room temperature to obtain a modified sepiolite adsorbent;

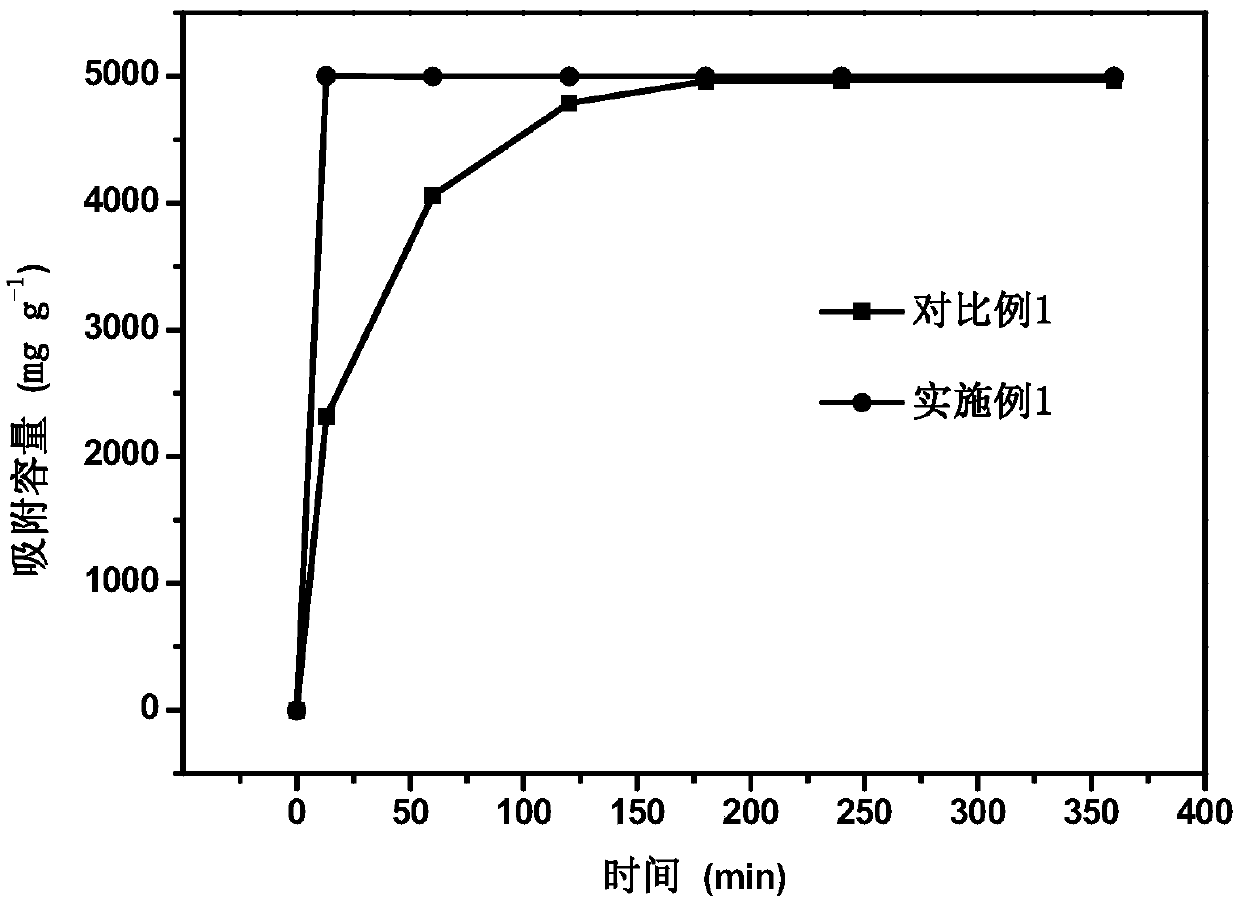

[0049] The method for quickly purifying malachite green sewage by the modified sepiolite adsorbent prepared by the present embodiment comprises the following steps:

[0050] Get the modified sepiolite adsorbent in the present embodiment of 0.0100g, add 10ml initial concentration is 5000mg L -1 malachite green solution, put it into a 50ml small test tube, put the small test tube into a magn...

Embodiment 2

[0056] In this embodiment, the preparation process and conditions are basically the same as in Example 1, except that in step (2) the -1 The flow continues to flow into N 2 Perform high temperature treatment.

[0057] The modified sepiolite adsorbent prepared in this example is adjusted to an initial concentration of 4500-5500 mg L according to the same conditions as in Example 1. -1 malachite green solution for adsorption. The results show that the maximum adsorption capacity of the modified sepiolite adsorbent in this example to the malachite green solution is 4999.60mg g -1 , the removal rate is 99.99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| External specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com