Water transfer printing tearable film resin, preparation method thereof and water transfer printing tearable film composition

A technology of water transfer printing and composition, applied in the field of resin, can solve the problems of low conversion rate of solid resin, high viscosity of resin solution, low molecular weight of resin, etc., and achieve good screen printing workability and good resistance to plasticizer migration , the effect of large resin molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Water transfer printing tearable film resin, its weight percentage is composed of: n-butyl methacrylate 29.2%, methyl methacrylate 10%, hydroxyethyl methacrylate 1%, cyclohexyl methacrylate 1.5%, methyl Acrylic acid 0.5%, ethoxyethoxyethyl acrylate 3%, dibutyl fumarate 0.8%, di-tert-butyl peroxide 1%, mesitylene 53%;

[0029] The above raw materials are prepared through the following steps: (1) add 70% of the amount of trimethylbenzene to the reactor as a reaction solvent; (2) add n-butyl methacrylate, methyl methacrylate, hydroxyethyl methacrylate, methyl 65% of cyclohexyl acrylate, ethoxy ethoxy ethyl acrylate, dibutyl fumarate, and di-tert-butyl peroxide are sucked into the drop tank, stirred evenly, and set aside; (3) heating, in Under the condition of 100°C heat preservation, evenly add acrylic acid monomer dropwise, and the dropwise addition is completed in 3.5 hours; (4) Continue heat preservation reaction at 110°C for 1.5 hours, add methacrylic acid to the react...

Embodiment 2

[0034] Water transfer printing tearable film resin, its components by weight percentage are: 25% isobutyl methacrylate, 15% methyl acrylate, 0.5% hydroxypropyl methacrylate, 1% isobornyl acrylate, 2% styrene , glycidyl methacrylate 2%, dibutyl maleate 2%, benzoyl tert-butyl peroxide 1.5%, trimethylbenzene 51%;

[0035] The above-mentioned raw materials are prepared through the following steps: (1) adding 80% of the amount of trimethylbenzene to the reactor as a reaction solvent; (2) mixing isobutyl methacrylate, methyl acrylate, hydroxypropyl methacrylate, isobornyl acrylate , glycidyl methacrylate, dibutyl maleate, 70% of the amount of tert-butyl peroxybenzoate are inhaled into the monomer drop tank, stirred evenly, and set aside; (3) heating, under the condition of 100 ℃ heat preservation, Add acrylic acid monomer dropwise evenly, and finish dropping in 3 hours; (4) Continue heat preservation reaction at 105°C for 2 hours, add 15% of styrene and tert-butyl peroxybenzoate to ...

Embodiment 3

[0040] A kind of water transfer printing tearable film composition, by weight percentage, is made up of following components: the tearable film resin that makes in the embodiment 1 80%, trimethylbenzene 10%, tetramethylbenzene 6%, phthalic acid two Butyl ester 1%, BYK-066N 0.5%, Tego 406 1%, β-(3,5-di-tert-butyl-4-hydroxyphenyl) isooctyl propionate 1%, Heli Chemical 1956 0.5%, After stirring and mixing each component according to the above weight percentage at room temperature, a water-transferable tearable film composition is obtained.

[0041] Performance Testing:

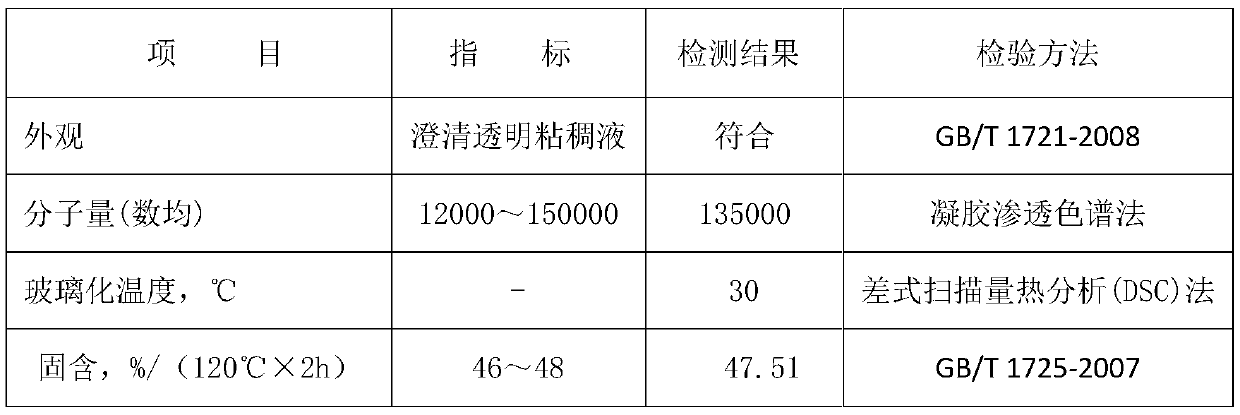

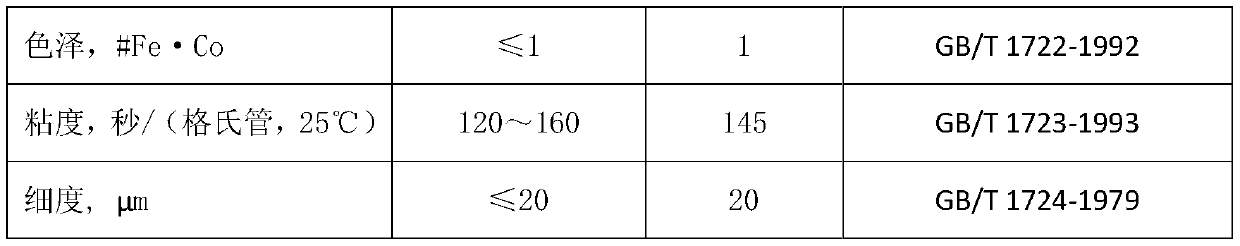

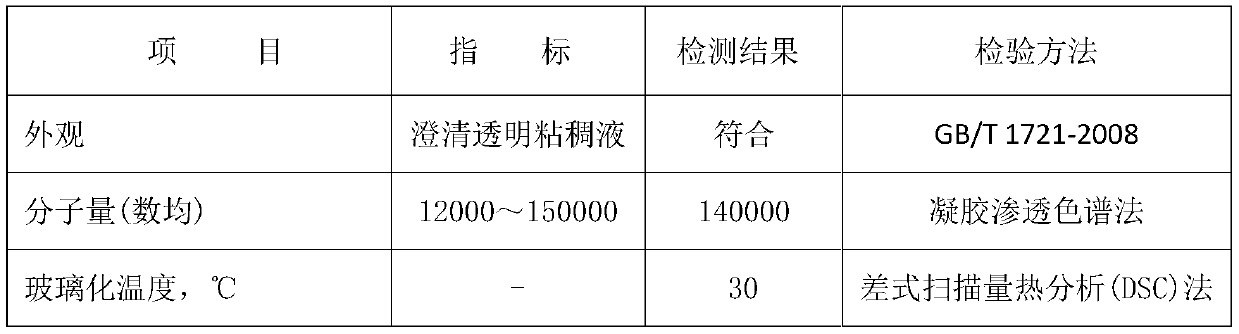

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com