Coenzyme factor compound, enzyme electrode, enzyme sensor as well as preparation method and application thereof

An enzyme sensor and complex technology, applied in the field of detection and analysis, can solve the problems of slow electron transfer rate, difficult regeneration, unsatisfactory kinetic characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0174] Embodiment 1 Chitosan-NAD + Preparation of complex

[0175] Take NAD + Add 1 mL of iodoacetic acid (1 mg / mL) to 5 mL (1 mg / mL) of the aqueous solution, and react in a water bath at 70 °C for 1 h. In the above NAD + Add 1 mL (1.3 mM) of sodium thiosulfate solution to the aqueous solution, adjust the pH to 11 with 1 M NaOH, and react in a water bath at 70°C for 1 h. After that, 1 mL of formaldehyde was added to react in a 70°C water bath for 1 h. Use 1M HCl to adjust the pH of the reaction system to be neutral, add NHS (10mg), EDC (10mg), add 0.1% chitosan solution 10mL [chitosan is medium viscosity chitosan (200-400mPa.s)], React in a water bath at 70°C for 1h. Carry out UV absorption full-wavelength scanning test for key steps.

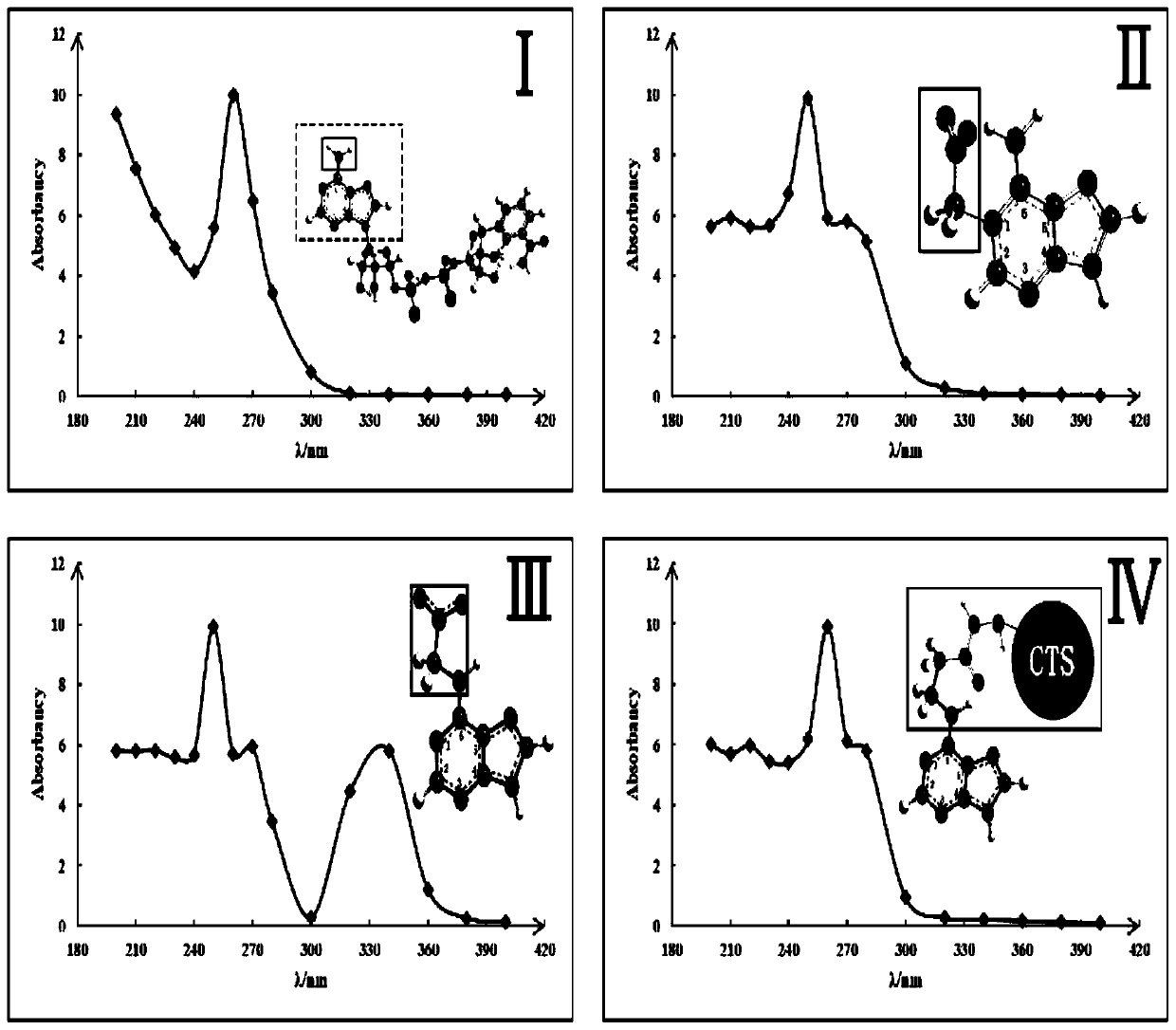

[0176] Chitosan-NAD + The UV absorption wavelength results during the preparation of the composite are as follows figure 1 As shown, we mainly use NAD + Covalent linkage with chitosan with good water solubility and good film-forming pr...

Embodiment 2

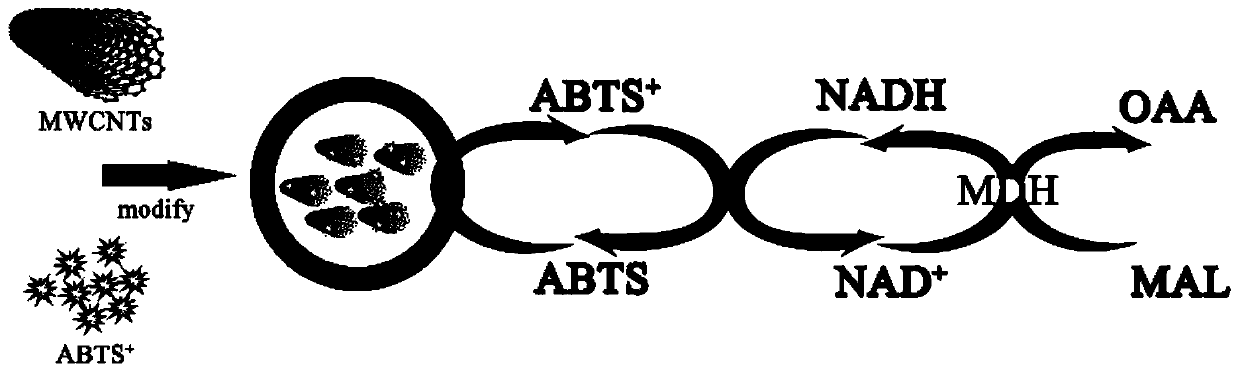

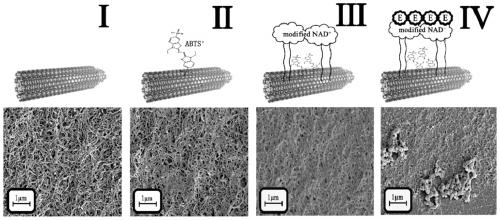

[0177] The preparation method of embodiment 2 malate dehydrogenase electrode

[0178] (1) Preparation of Chitosan-NAD + Complex

[0179] Take NAD + Add 1 mL of iodoacetic acid (1 mg / mL) to 5 mL (1 mg / mL) of the aqueous solution, and react in a water bath at 70 °C for 1 h. In the above NAD + Add 1 mL (1.3 mM) of sodium thiosulfate solution to the aqueous solution, adjust the pH to 11 with 1 M NaOH, and react in a water bath at 70°C for 1 h. After that, 1 mL of formaldehyde was added to react in a 70°C water bath for 1 h. Use 1M HCl to adjust the pH of the reaction system to be neutral, add NHS (10mg), EDC (10mg), add 0.1% chitosan solution 10mL [chitosan is medium viscosity chitosan (200-400mPa.s)], React in a water bath at 70°C for 1h.

[0180] (2) Preparation of malate dehydrogenase electrode

[0181] All electrochemical measurements were performed in a typical three-electrode system (CHI 760D, CH Instruments). The composition of the three-electrode system includes: a...

Embodiment 3

[0191] Embodiment 3 The preparation method of glucose dehydrogenase electrode

[0192] (1) Preparation of glucose dehydrogenase electrode

[0193] All electrochemical measurements were performed in a typical three-electrode system (CHI 760D, CH Instruments). The composition of the three-electrode system includes: a platinum electrode as a counter electrode, an Ag / AgCl electrode as a reference electrode, and a glassy carbon electrode as a working electrode. During the experiment, the glassy carbon electrode with a diameter of 3mm was sequentially filled with Al with a certain particle size 2 o 3 The slurry was polished to a mirror surface on a polishing cloth. After each polishing, the surface dirt was washed off first, and then moved into an ultrasonic water bath for cleaning, each time for 1 min, and repeated three times. Finally, 1:1 ethanol, 1:1 NHO 3 Ultrasonic cleaning. After thorough washing, in 0.20mol / L KNO 3 Medium record 1×10 -3 mol / L K 3 Fe(CN) 6 The cyclic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Snr | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com