A kind of positively charged composite nanofiltration membrane, its preparation method and application

A composite nanofiltration membrane, positively charged technology, applied in the field of membrane separation, can solve problems such as poor separation effect, and achieve the effect of improving positive charging strength, excellent water flux, and reducing steric hindrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

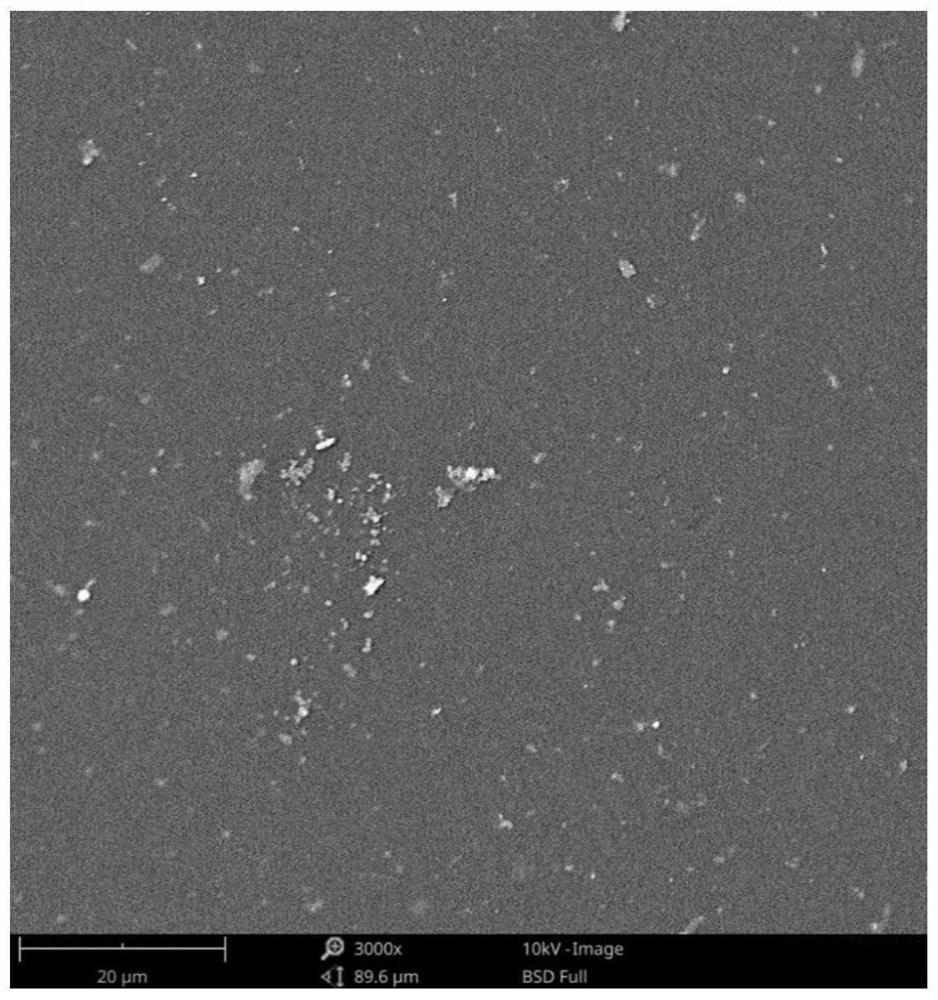

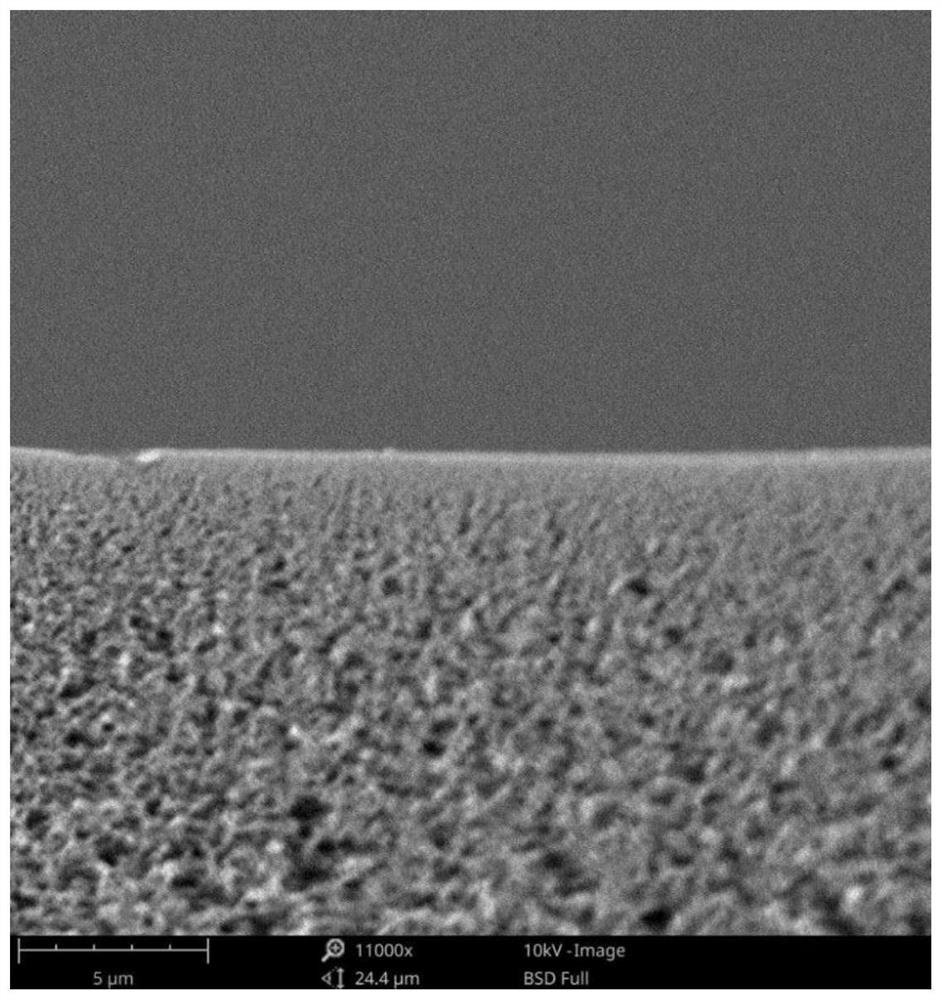

Image

Examples

Embodiment 1

[0038] This example is the preparation of the positively charged composite nanofiltration membrane sample 1, wherein the positively charged nanofiltration selective layer in the positively charged composite nanofiltration membrane sample 1 is provided with positively charged groups by polyethyleneimine.

[0039] Prepare a 3wt% polyethyleneimine aqueous phase solution, stir until it is completely dissolved, and use it as the first phase;

[0040] Prepare 0.05wt% trimesoyl chloride organic phase solution, the organic solvent is n-hexane, as the second phase;

[0041] Fix the polyethersulfone base membrane on the self-made PTFE interfacial polymerization mold, pour a certain amount of the first phase solution to immerse the surface of the membrane, make it contact with the surface for 100 seconds, take it out, and then roll the polyethersulfone support membrane with a rubber roller , remove the excess solution, pour the same amount of the second phase, soak for 100 seconds, rinse...

Embodiment 2

[0043] This example is the preparation of the positively charged composite nanofiltration membrane sample 2, wherein the positively charged nanofiltration selective layer in the positively charged composite nanofiltration membrane sample 2 is provided with positively charged groups by quaternized polyethyleneimine.

[0044] The method for quaternizing polyethyleneimine in this embodiment: use propylene oxide to tertiary aminate the raw material polyethyleneimine, and then use benzyl chloride to quaternize the tertiary-aminated polyethyleneimine.

[0045] Prepare a 3wt% aqueous solution of quaternized polyethyleneimine, stir until it is completely dissolved, and use it as the first phase;

[0046] Prepare 0.05wt% trimesoyl chloride organic phase solution, the organic solvent is n-hexane, as the second phase;

[0047] Fix the polyethersulfone base membrane on the self-made PTFE interfacial polymerization mold, pour a certain amount of the first phase solution to immerse the surf...

Embodiment 3

[0049] This example is the preparation of the positively charged composite nanofiltration membrane sample 3, wherein the positively charged nanofiltration selective layer in the positively charged composite nanofiltration membrane sample 3 is provided with positively charged groups by quaternized polyethyleneimine.

[0050] In this embodiment, the method for quaternizing polyethyleneimine is the same as that in Embodiment 2.

[0051] The preparation mass fraction is the aqueous phase solution of the quaternized polyethyleneimine of 3wt%, the DMAP of 0.01wt%, the triethylamine of 0.03wt%, the sodium dodecylbenzene sulfonate of 0.005wt%, stir, until complete dissolved, as the first phase;

[0052] Prepare 0.05wt% trimesoyl chloride organic phase solution, the organic solvent is n-hexane, as the second phase;

[0053] Fix the polyethersulfone base membrane on the self-made PTFE interfacial polymerization mold, pour a certain amount of the first phase solution to immerse the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com