Corn straw oil stain adsorbent for oil field, and preparation method thereof

A technology of corn stalks and adsorbents, which is applied in the field of corn stalk oil pollution adsorbents for oilfields and its preparation, can solve the problems of inconvenient application, waste of petroleum resources, and small adsorption capacity, and achieve improved adsorption capacity, adsorption efficiency, and improved adsorption capacity. Performance, the effect of improving the adsorption site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

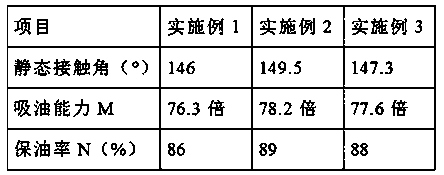

Examples

Embodiment 1

[0049] S1: Prepare materials:

[0050] Weigh polyvinyl alcohol, calcium chloride, glutaraldehyde, trimethylsilane, reduced graphene oxide, sodium alginate, sodium periodate and ethylene glycol in proportion, and set aside;

[0051] Weigh zinc nitrate hexahydrate, 2-methylimidazole, methanol, N,N-dimethylformamide, polyacrylonitrile, corn straw, nano-silica, toluene, sodium chlorite, sodium hydroxide and ethanol, spare;

[0052] S2: Preparation of pretreated fibers:

[0053] Take corn stalks, cut them into small pieces of 2 cm, soak them in water for 6 hours, then soak them in nano-silica emulsion for 8 hours, explode them with high-pressure steam for 3 times, stir them at high speed for 10 minutes after the explosions, and let them stand to dry to obtain material A;

[0054] Take toluene and ethanol, stir and mix for 10 minutes, then add material A, extract in oil bath at 90°C for 6 hours, wash with ethanol, and dry at room temperature to obtain material B; take sodium chlor...

Embodiment 2

[0069] S1: Prepare materials:

[0070] Weigh polyvinyl alcohol, calcium chloride, glutaraldehyde, trimethylsilane, reduced graphene oxide, sodium alginate, sodium periodate and ethylene glycol in proportion, and set aside;

[0071] Weigh zinc nitrate hexahydrate, 2-methylimidazole, methanol, N,N-dimethylformamide, polyacrylonitrile, corn straw, nano-silica, toluene, sodium chlorite, sodium hydroxide and ethanol, spare;

[0072] S2: Preparation of pretreated fibers:

[0073] Take corn stalks, cut them into 3cm pieces, soak them in water for 7 hours, then soak them in nano-silica emulsion for 9 hours, explode them with high-pressure steam for 3-4 times, stir them at high speed for 15 minutes after the explosions, and let them stand to dry to obtain material A;

[0074] Take toluene and ethanol, stir and mix for 13 minutes, then add material A, extract in oil bath at 91°C for 7 hours, wash with ethanol, and dry at room temperature to obtain material B; take sodium chlorite and ...

Embodiment 3

[0089] S1: Prepare materials:

[0090] Weigh polyvinyl alcohol, calcium chloride, glutaraldehyde, trimethylsilane, reduced graphene oxide, sodium alginate, sodium periodate and ethylene glycol in proportion, and set aside;

[0091] Weigh zinc nitrate hexahydrate, 2-methylimidazole, methanol, N,N-dimethylformamide, polyacrylonitrile, corn straw, nano-silica, toluene, sodium chlorite, sodium hydroxide and ethanol, spare;

[0092] S2: Preparation of pretreated fibers:

[0093] Take corn stalks, cut them into small pieces of 4 cm, soak them in water for 8 hours, then soak them in nano-silica emulsion for 10 hours, explode them with high-pressure steam for 4 times, stir them at high speed for 20 minutes after the explosions, and let them stand to dry to obtain material A;

[0094] Take toluene and ethanol, stir and mix for 15 minutes, then add material A, extract in oil bath at 92°C for 8 hours, wash with ethanol, and dry at room temperature to obtain material B; take sodium chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com