Ceramic micro-crack repairing method

A repair method, ceramic micro technology, applied in the field of repair of ceramic materials, can solve problems such as repair after breakage, achieve the effects of increasing the use limit, promoting environmental protection, and reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

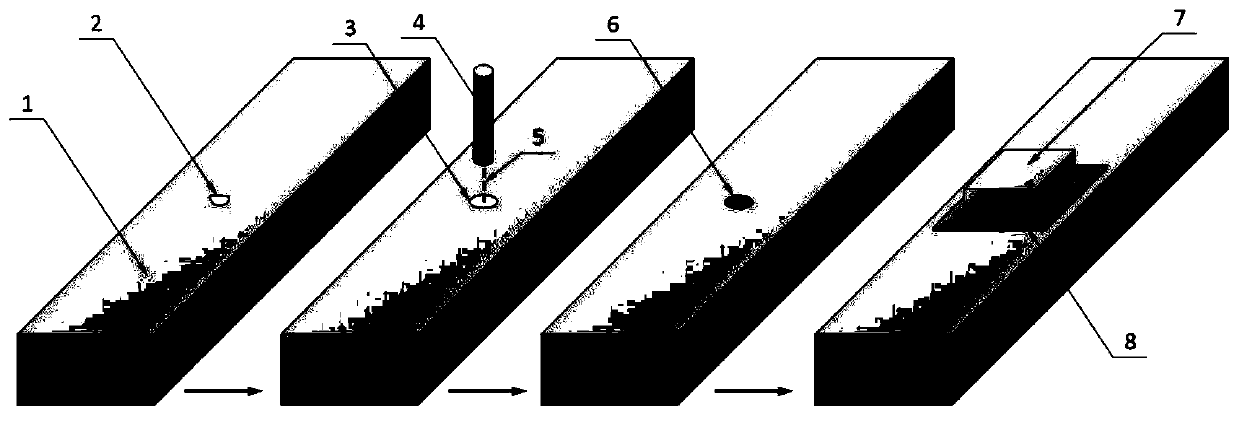

[0030] A method for repairing ceramic microcracks, comprising the steps of:

[0031] Use the non-destructive testing process to find and extract the size characteristic parameters of the micro-cracks 2 on the ceramic part 1, especially the depth value of the micro-cracks 2; the ceramic part 1 can be a boride ceramic part, an oxide ceramic part, a nitride ceramic part or Carbide ceramic parts;

[0032] Under the condition of vacuum or inert gas protection, the micro-crack 2 area is processed into micro-holes 3 through the fiber laser processing process. The fiber laser 4 is required in the fiber laser processing process. The parameters of the fiber laser 4 are based on the size characteristics of the micro-crack 2 In the fiber laser processing process, the processing power is 0.1-10W, the processing frequency is 1-1000 times, and the processing speed is 0.1-100mm / s; the micro-hole 3 is a blunt hole, such as a hemispherical hole, a semi-ellipse Shaped holes, the tip radius of t...

Embodiment 2

[0039] a ZrB 2 -SiC ceramic micro-crack repair method, comprising the following steps:

[0040] Step 1: Indentation method on ZrB 2 -SiC ceramic sample (3×4×36mm 3 ) artificially introduce micro-cracks 2 on the surface, polish and remove the indentation pit, leaving only semi-circular micro-cracks 2, the length and depth of micro-cracks 2 obtained by CT non-destructive testing are about 50 μm and 25 μm, respectively;

[0041] Step 2: Using the fiber laser processing parameters of processing power of 3W, processing times of 5 times, and processing speed of 10mm / s, the microcrack 2 is processed into a microhole with a tip radius of 29 μm, a length of 75 μm, and a depth of 36 μm 3. After polishing with 1000-grit sandpaper, ultrasonic cleaning in acetone medium for 30 minutes;

[0042] Step 3: the cleaned ZrB 2 - SiC ceramic samples were placed in an annealing furnace, annealed at 1200°C for 30 minutes under argon protection, and then cooled to room temperature;

[0043] Step...

Embodiment 3

[0048] A kind of Si 3 N 4 Ceramic microcrack repair method, other operations in this embodiment are the same as in Example 2, the difference is that the length and depth of the microcrack 2 are about 200 μm and 50 μm respectively, the processing power is 5W, the number of processing is 20 times, and the processing speed is 50mm / s fiber laser processing process parameters, the microcrack 2 is processed into a microhole 3 with a tip radius of 49 μm, a length of 480 μm, and a depth of 52 μm. The brazing material 6 is Ag-28Cu, and the brazing process is under the protection of argon. Heat to 760°C at a heating rate of 20°C / min, then hold for 10 minutes, then continue to heat at a heating rate of 10°C / min to 860°C, hold for 5 minutes, and then slowly cool to room temperature with the furnace.

[0049] Measurement of pristine microcrack-free Si by three-point bending test 3 N 4 Ceramic sample, containing semicircular micro-crack Si 3 N 4 Ceramic specimens and repaired Si 3 N ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com