Saccharomyces cerevisiae strain tolerant to vanillic acid, p-hydroxybenzoic acid and syringic acid and application of Saccharomyces cerevisiae strain

A technology of Saccharomyces cerevisiae strain and p-hydroxybenzoic acid, which is applied in the biological field, can solve the problems of inhibiting ethanol fermentation rate and lethality, and achieve good growth, ethanol fermentation performance, and enhanced tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 Adaptive Evolution of Saccharomyces cerevisiae

[0038] The adaptive evolution method for obtaining the Saccharomyces cerevisiae strain PAT01 that is resistant to high concentrations of vanillic acid, p-hydroxybenzoic acid and syringic acid includes the following steps:

[0039] (1) Configuration of synthetic medium (g / L): anhydrous glucose 20, potassium dihydrogen phosphate 2, magnesium sulfate 1, ammonium sulfate 1, yeast extract 10; sterilize at 121°C for 20 minutes.

[0040] (2) The configuration of the phenolic acid inhibitor culture medium: Add a mixture of vanillic acid, p-hydroxybenzoic acid and syringic acid to the above-mentioned sterilized synthetic medium (where vanillic acid concentration is 0.80-2.50g / L, p-hydroxybenzoic acid) The concentration of benzoic acid is 0.50-1.80g / L and the concentration of syringic acid is 0.40-1.20g / L) to make phenolic acid inhibitor medium.

[0041] (3) Saccharomyces cerevisiae's adaptive evolution to mixed phenolic acid inh...

Embodiment 2

[0044] Example 2 Verification of tolerance of yeast strain PAT01 to mixed phenolic acid

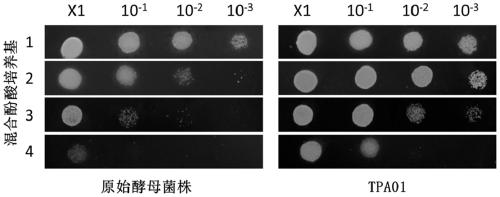

[0045] (1) Comparison of the growth of the mixed phenolic acid plate: Adjust the cell density of the yeast strain PAT01 and the original yeast strain activated for 18 hours to an OD600 absorbance value of 6.0, and then dilute the cell suspension sequentially (10 -1 , 10 -2 , 10 -3 ), and pipet 5 μL of bacterial solution dropwise to different concentrations of mixed phenolic acid medium plates, and incubate at 30°C for 48 hours. Such as figure 1 As shown, the colony growth status of the yeast strain PAT01 is significantly better than the original yeast strain.

[0046] Among them, mixed phenolic acid solid medium: 1.5% (w / v) agar is added to the synthetic medium and sterilized at 121°C for 20 minutes. Vanillic acid, p-hydroxybenzoic acid and syringic acid were added to the sterilized synthetic medium to prepare mixed phenolic acid medium with different concentrations, as shown in Table 1.

[004...

Embodiment 3

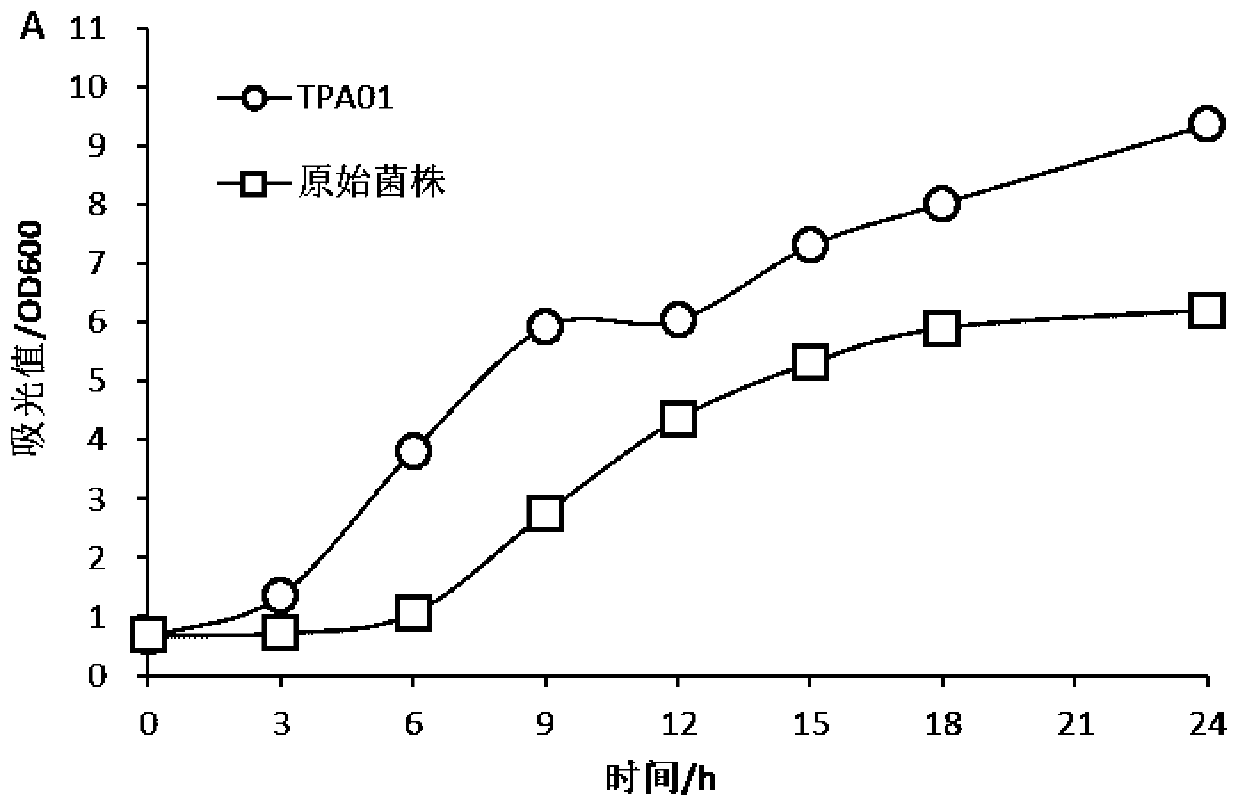

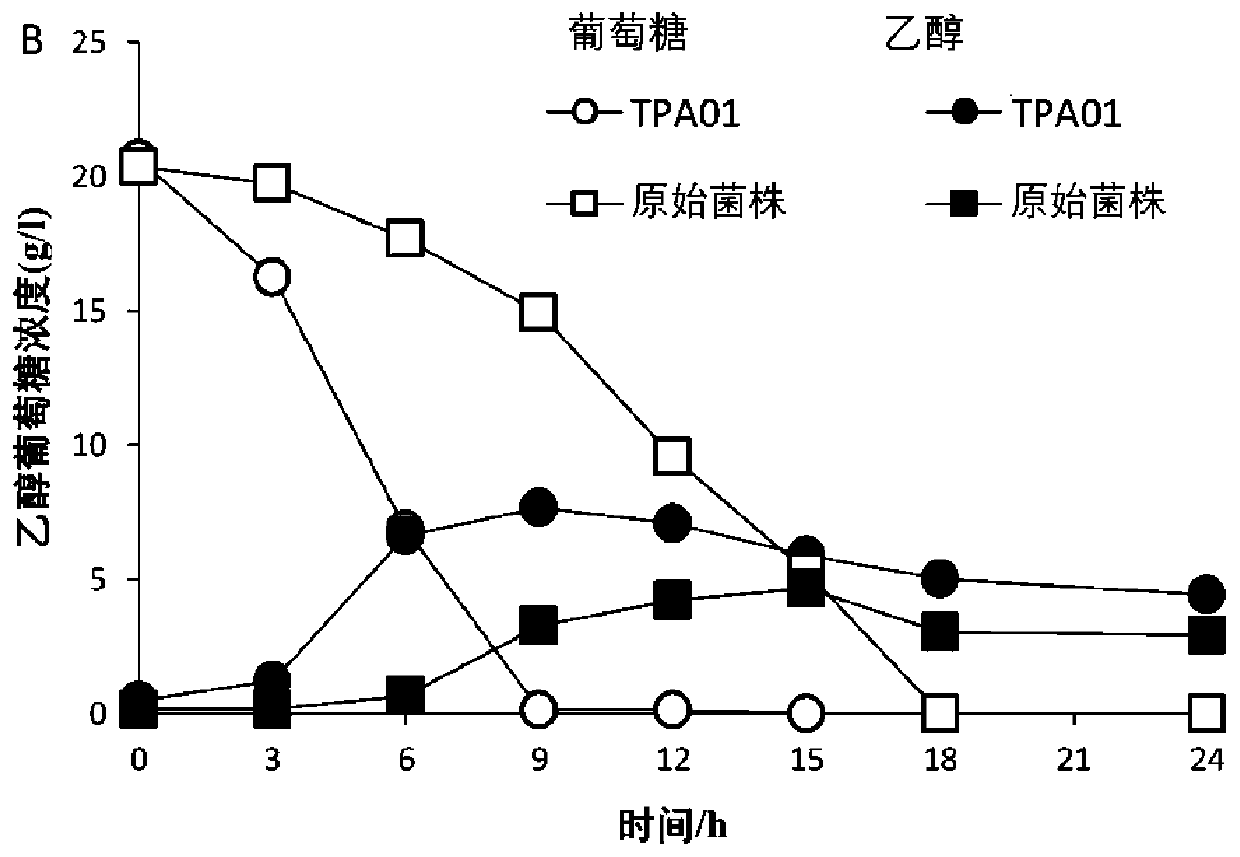

[0054] Example 3 Simultaneous saccharification and ethanol fermentation using industrial corncob residue

[0055] The activated yeast strain PAT01 and the original yeast strain were respectively transferred to the industrial corn cob residue fermentation product after pre-saccharification for 12 hours at a 10% inoculum for simultaneous saccharification and ethanol fermentation. Samples were taken every 12 hours to determine the ethanol and glucose in the fermentation broth. content.

[0056] Among them: industrial corncob residue is a by-product of dilute acid treatment of corncob to produce xylose, obtained from Shandong Longli Biotechnology Co., Ltd., with a cellulose content of 56.5% (based on dry matter);

[0057] Dilute acid method treatment conditions: material-to-liquid ratio 1:10 (mass ratio), dilute sulfuric acid concentration 4%, cooking at 121°C for 1 h, solid-liquid separation, and the solid part is corncob residue.

[0058] Corncob residue pre-saccharification conditions:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com