A method for modifying LPSO structure in magnesium alloy by native nano-dispersed phase

A disperse phase, magnesium alloy technology, applied in the field of non-ferrous metal alloy preparation, can solve the problems of lack of second phase particle pinning, high temperature thermal stability to be verified and other problems, achieve good application prospects, significant strengthening effect, overcome weak binding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

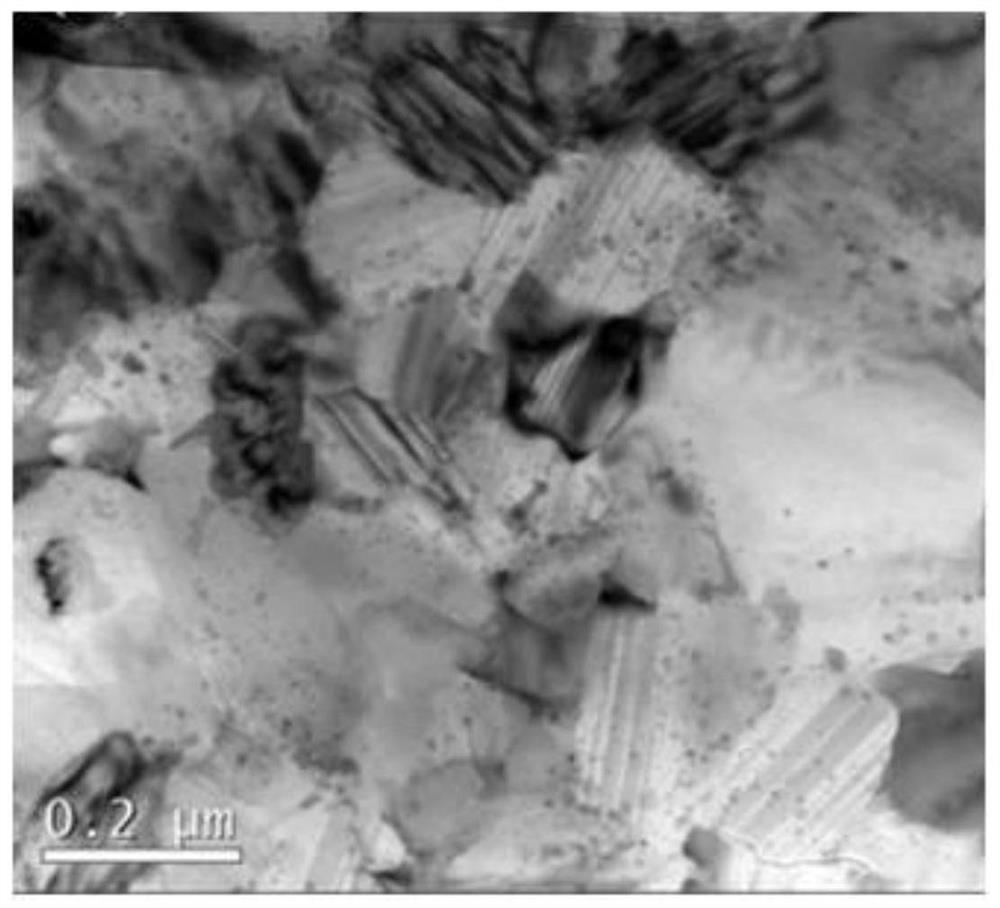

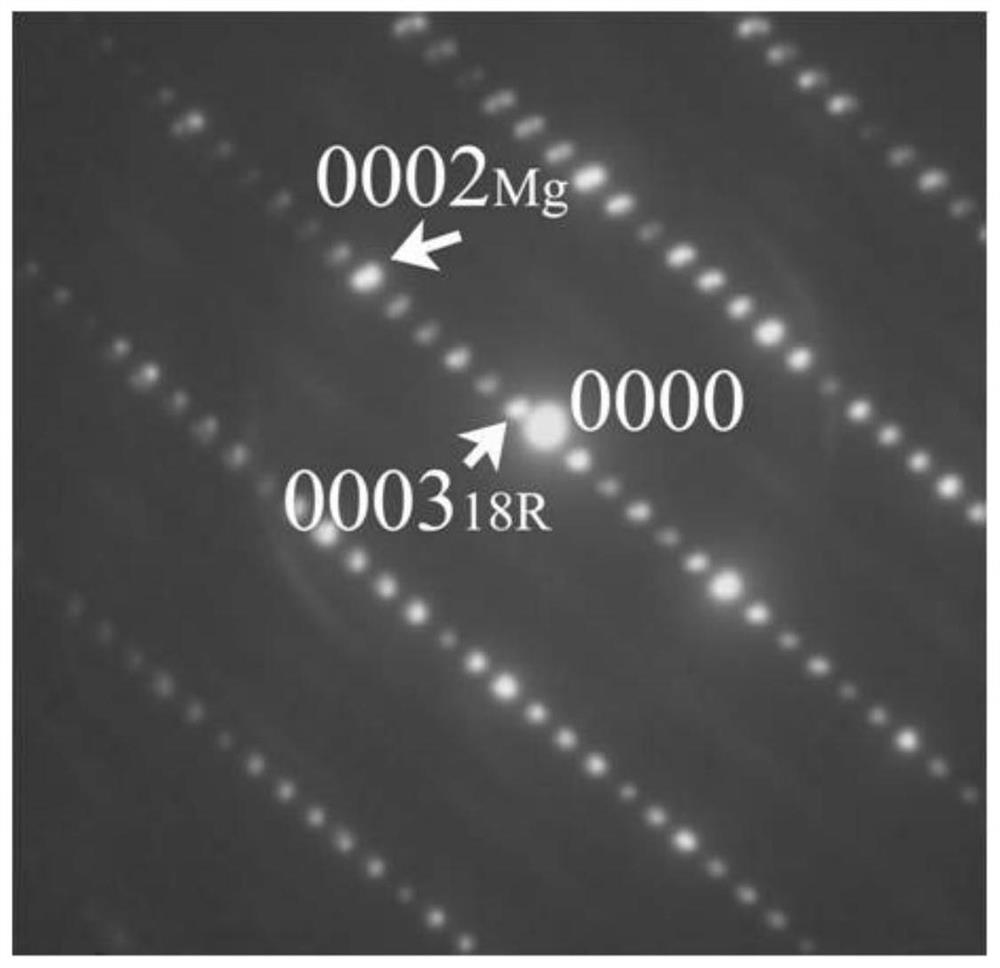

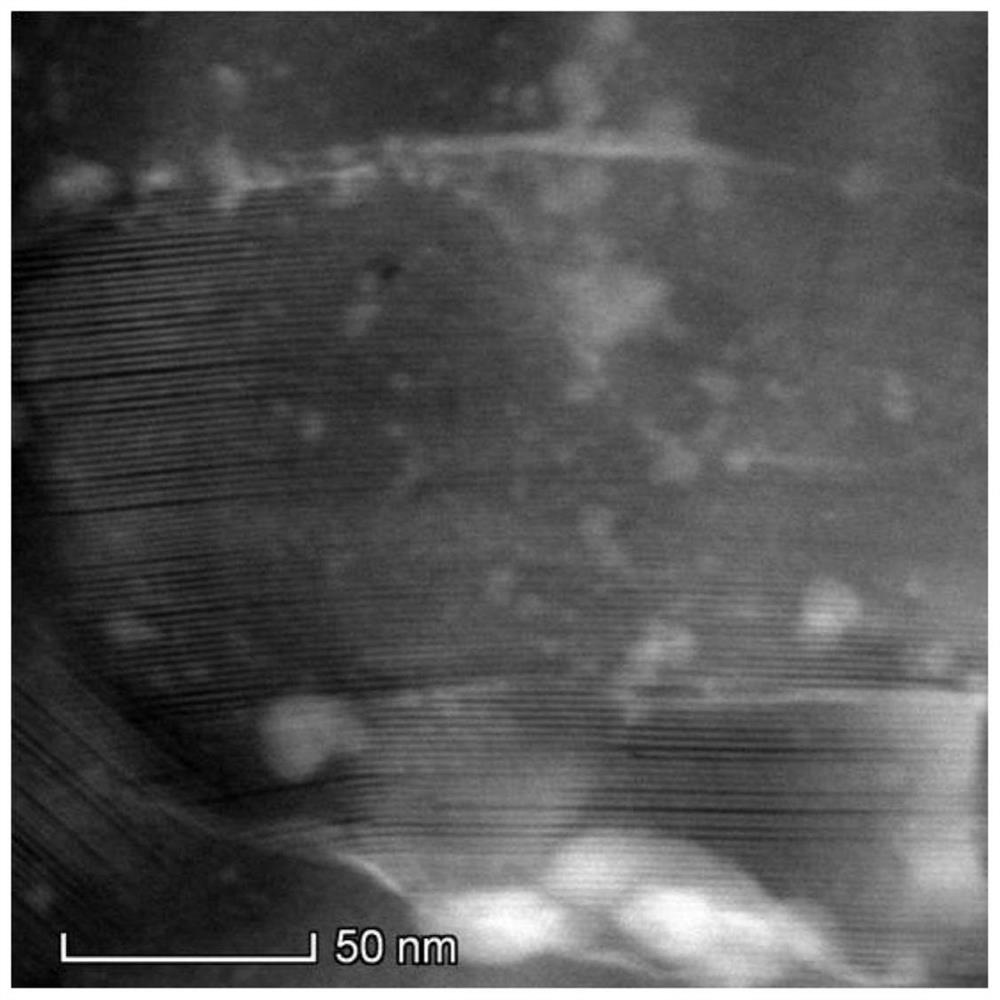

Image

Examples

Embodiment 1

[0045] In this embodiment, a method for modifying the LPSO structure in the original nanometer dispersed phase in the magnesium alloy is carried out according to the following steps:

[0046] (1) Preparation of LPSO pre-alloyed powder: LPSO alloy ingots were prepared by conventional magnesium alloy melting method, and the whole process was carried out in CO 2 with SF 6 Carried out under a mixed gas atmosphere, the main steps are as follows: according to the mass ratio of Mg: Zn: Y = 63.4: 12.0: 24.6 for batching; preheat the melting furnace to 400 ~ 500 ° C, and then add pure magnesium ingots to the crucible of the melting furnace In the middle, reheat to 700-750°C; after the magnesium ingot is melted, add Zn and Mg-Y intermediate alloys, then raise the furnace temperature by 10-30°C, keep it warm for 10-15 minutes, and then mechanically stir for 2-5 minutes; put the melting furnace Adjust the temperature to 700-720°C, keep it warm for 10-15 minutes, pour it into the mold, an...

Embodiment 2

[0050] In this embodiment, a method for modifying the LPSO structure in the original nanometer dispersed phase in the magnesium alloy is carried out according to the following steps:

[0051] (1) The first step of this embodiment is the same as step (1) in embodiment 1.

[0052] (2) Mechanical alloying and oxygen doping treatment: perform mechanical alloying and oxygen doping treatment on the pre-alloyed powder by an air oxidation method. The pre-alloyed powder was ultrasonically cleaned in alcohol for 10 min, and then dried in a vacuum oven. The drying temperature is 150°C, and the drying time is 5h. Weigh 5g of dried pre-alloyed powder, together with 10g of grinding steel balls, put it into a 50ml ball mill jar in air and seal it for mechanical alloying. The parameters of mechanical alloying are ball-to-material ratio of 2:1, rotation speed of 1000rpm, and scraping once every 0.5h of ball mill shutdown. The scraping of the first three shutdowns is carried out in the air, an...

Embodiment 3

[0056] In this embodiment, a method for modifying the LPSO structure in the original nanometer dispersed phase in the magnesium alloy is carried out according to the following steps:

[0057] (1) The first step of this embodiment is the same as step (1) in embodiment 1.

[0058] (2) Mechanical alloying and oxygen doping treatment: perform mechanical alloying and oxygen doping treatment on the pre-alloyed powder by magnesium oxide decomposition method. The pre-alloyed powder was ultrasonically cleaned in alcohol for 10 min, and then dried in a vacuum oven. The drying temperature is 150°C, and the drying time is 5h. The mixture powder is configured according to the proportion of MgO mass fraction being 5%, 5 g in total. Among them, LPSO pre-alloyed powder 4.75g, MgO powder 0.25g. Put the prepared mixture powder together with 10 g of grinding steel balls into a 50 ml ball mill jar in a glove box and seal it for mechanical alloying. The parameters of mechanical alloying are ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com