A kind of preparation method of zirconia dispersion strengthened copper alloy

A technology of dispersion strengthening and zirconia, which is applied in the field of metal matrix composite materials and preparation, can solve problems such as complex process, low diffusion efficiency, and low solid solubility of oxygen, and achieve simple process, high diffusion efficiency, and solid solubility big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1 ODS-Cu alloy with nominal composition Cu -0.2 wt.% Zr

[0017] Step 1, the preparation composition is Cu 75 Zr 25 Alloy Ingots and Amorphous Ribbons

[0018] Using Cu (99.99%) and Zr (99.9%) metal raw materials, the atomic percentage composition is Cu 75 Zr 25 Converted into weight percentage components, weighed and prepared Cu-Zr alloy, mixed the raw materials and placed them in the water-cooled copper crucible of the non-consumable arc melting furnace, and then evacuated to 5×10 -3 - 1×10 -2 Pa, and then filled with 0.01 - 0.08 MPa of pure argon protective gas for melting, the working current of arc melting is 150-200 A; then turn the alloy ingot up and down, and repeat the melting for 3 times to obtain an alloy ingot with uniform composition;

[0019] The alloy ingot is crushed and put into a quartz tube, and the diameter of the nozzle of the quartz tube is about 1-1.5 mm. Put the charged quartz tube in the induction heating coil, use the vacuum cop...

Embodiment 2

[0026] Example 2 ODS-Cu alloy with nominal composition Cu -10.0 wt.% Zr

[0027] Step 1, prepare atomic percentage composition Cu 50 Zr 50 Alloy ingots with amorphous strips:

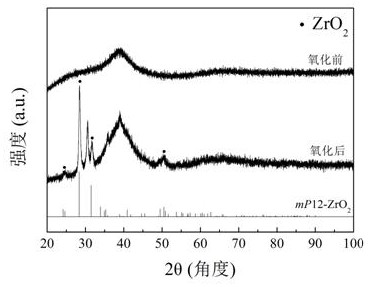

[0028] Same as Step 1 in Embodiment 1. Cu was determined by X-ray diffraction 50 Zr 50 The amorphous map is attached figure 1 As shown, its crystallization temperature Tx is 460°C.

[0029] Step two, Cu 50 Zr 50 Oxidation of amorphous strips:

[0030] Same as Step 2 in Embodiment 1. Cu here 50 Zr 50 The oxidation treatment temperature of the amorphous is 360°C, and the heat preservation time is 3 h, the obtained Cu 50 Zr 50 The X-ray diffraction pattern of oxide amorphous figure 1 shown.

[0031] Step 3, melting and preparing ODS-Cu alloy

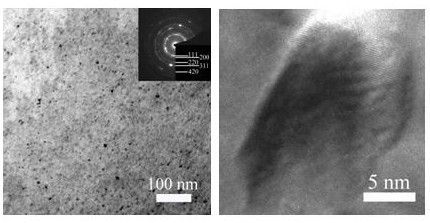

[0032] Same as Step 3 in Embodiment 1. The microstructure is similar to that of the alloy in Example 1, the particles of the oxide strengthening phase are slightly larger (average diameter 10 nm), and the distribution density is nearly 15% higher tha...

Embodiment 3

[0033] Example 3 ODS-CuCrZr alloy with nominal composition Cu-0.75 wt.%Cr-0.2 wt.%Zr

[0034] Step 1, the preparation composition is Cu 75 Zr 25 Alloy Ingots and Amorphous Ribbons

[0035] Same as Step 1 in Embodiment 1.

[0036] Step two, Cu 75 Zr 25 Oxidation of amorphous strips

[0037] Same as Step 2 in Embodiment 1.

[0038] Step 3, melting and preparing ODS-CuCrZr alloy

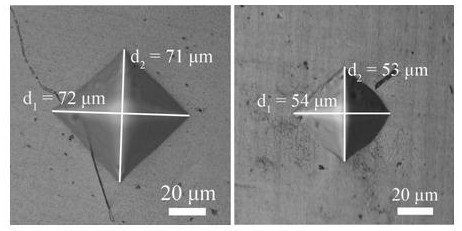

[0039] Same as Step 3 in Embodiment 1. Adding 0.75 wt.% Cr, direct smelting to obtain ZrO with both precipitation strengthening and dispersion strengthening effects 2 Dispersion-strengthened CuCrZr alloy, its microstructure and morphology are similar to that of Example 1. The performance test results show that the as-rolled hardness of the cast ODS-CuCrZr alloy is 145 HV0.2 / 20, the room temperature tensile strength exceeds 420 MPa, and its room temperature plastic strain is 10%, but its room temperature conductivity is only 35% IACS; After proper solution aging treatment, the room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com