High-performance boron carbide grinding medium as well as preparation method and application thereof

A grinding medium and boron carbide technology, applied in chemical instruments and methods, other chemical processes, grain processing, etc., can solve the problems of low grinding medium strength, poor grinding effect, and low grinding efficiency, so as to improve grinding efficiency and wear resistance Good performance and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

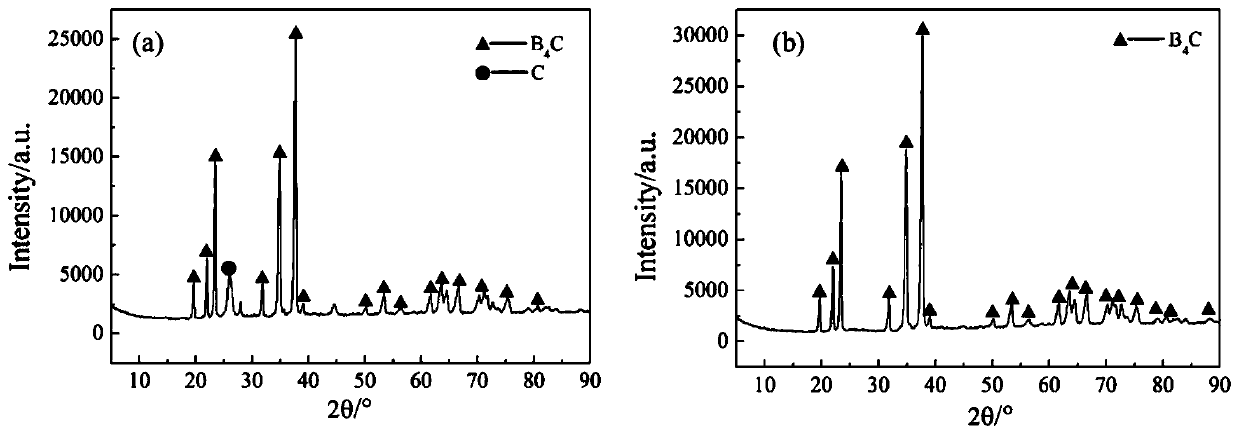

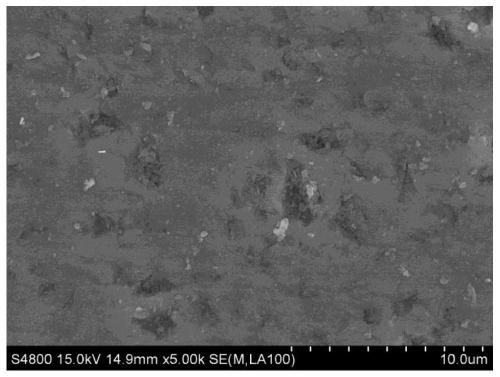

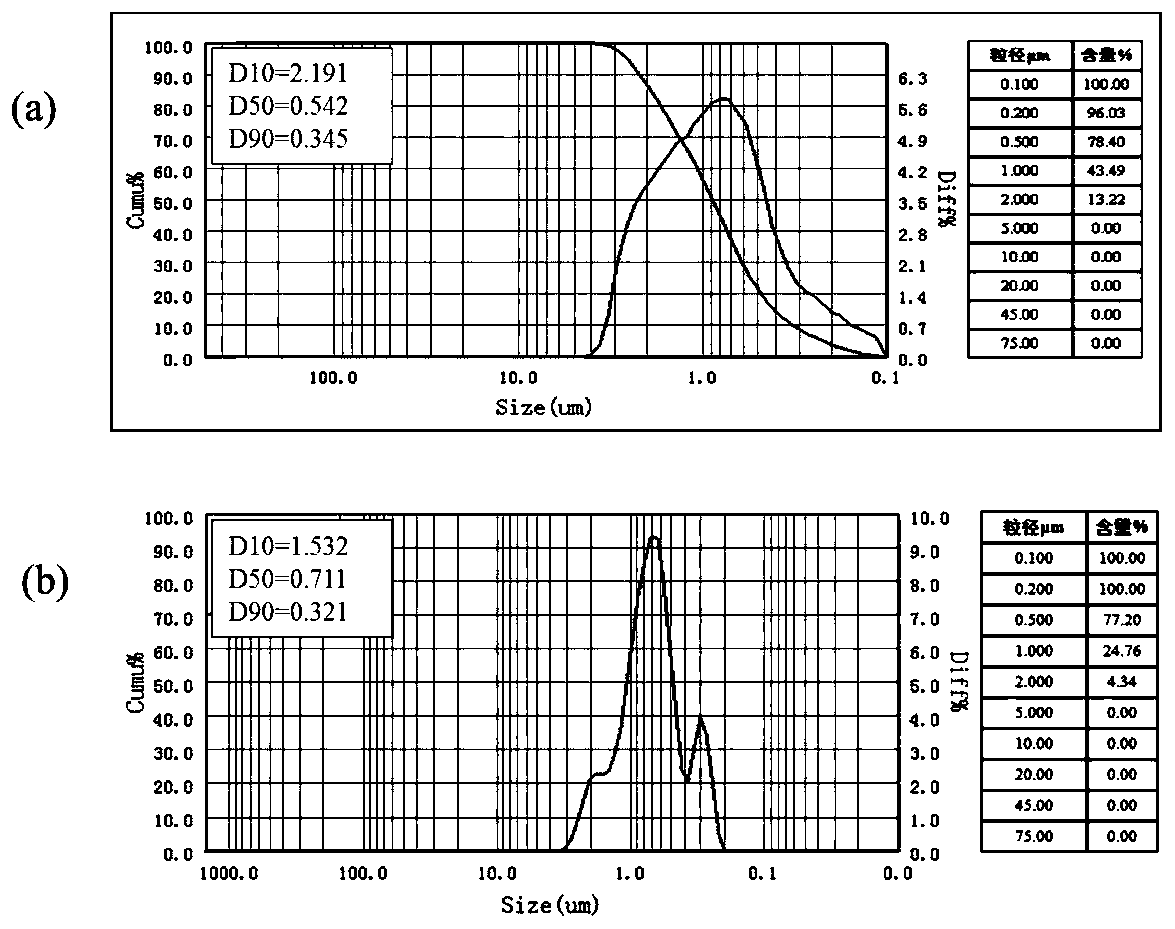

[0032] Take B with a boron-carbon molar ratio of 3.9 and an average particle size of 0.5 μm 4 99.8g of raw material C and 0.2g of polyvinylidene fluoride were wet-milled in a ball mill tank for 5 hours, then taken out, and the mixed powder was dried in a vacuum oven at 80°C for 6 hours, and then passed through an 80-mesh sieve to make balls into B 4 C particles, the particles are placed in a quasi-elliptical mold with a major axis of 6mm and an aspect ratio of 2:1, and the pressure is maintained at 30MPa on a cold isostatic press for 10 minutes to form a green body, and the green body is subjected to multi-stage vacuum processing. For pressureless sintering, first raise the temperature to 500°C at a heating rate of 10°C, hold for 80 minutes, then raise the temperature to 1500°C at a heating rate of 3°C, hold for 120 minutes, then raise the temperature to 1800°C at 5°C, hold for 240 minutes, and then cool with the furnace to obtain The primary grinding medium is oval-shaped, an...

Embodiment 2

[0042] Take B with a boron-carbon molar ratio of 4.5 and an average particle size of 5 μm 4 87g of raw materials C, 10g of polyvinyl chloride, and 3g of polyurethane were wet-milled in a ball mill tank for 15 hours, then taken out, and the mixed powder was dried in a vacuum oven at 120°C for 4 hours, and then passed through a 150-mesh sieve to make balls into B 4 C particles, the particles are placed in a quasi-elliptical mold with a major axis of 24mm and a length-to-diameter ratio of 6:1, and the pressure is maintained at 120MPa on a cold isostatic press for 6 minutes to form a green body, and the green body is subjected to multi-stage under vacuum conditions. For pressureless sintering, first raise the temperature to 600°C at a heating rate of 20°C, hold for 20 minutes, then raise the temperature to 1700°C at a heating rate of 15°C, hold for 30 minutes, then raise the temperature to 2000°C at 8°C, hold for 60 minutes, and then cool with the furnace to obtain Oval-like prima...

Embodiment 3

[0044] Take B with a boron-carbon molar ratio of 4.0 and an average particle size of 2 μm 4 94g of raw material C, 4.5g of polyvinyl chloride, and 1.5g of dextrin were wet-milled in a ball mill tank for 10 hours, then taken out, and the mixed powder was dried in a vacuum oven at 220°C for 0.5 hours, and then passed through a 200-mesh sieve to make ball into B 4 C particles, the particles are placed in a quasi-elliptical mold with a major axis of 15mm and an aspect ratio of 3:1, and the pressure is maintained at 200MPa on a cold isostatic press for 4 minutes to form a green body, and the green body is subjected to multi-stage vacuum processing. For pressureless sintering, first raise the temperature to 560°C at a heating rate of 12°C, hold for 50 minutes, then raise the temperature to 1600°C at a heating rate of 8°C, hold for 80 minutes, then raise the temperature to 1900°C at 6°C, hold for 120 minutes, and then cool with the furnace to obtain Oval-like primary grinding medium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com