VOCs adsorbent prepared from hypha solid waste resources and coal, and preparation method thereof

A technology of adsorbent and mycelium, which is applied in the field of high-performance VOCs adsorbent and its preparation, can solve the problems of poor adsorption performance and short life, and achieve the effect of strong adsorption performance, stable structure strength and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

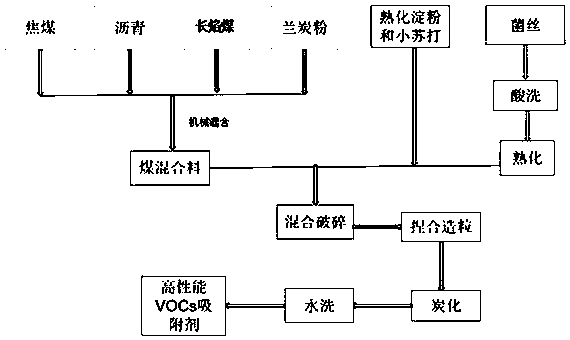

Method used

Image

Examples

Embodiment 1

[0028] ① Take 1.3kg of coking coal, 0.7kg of asphalt, 1.5kg of long-flame coal, and 1.2kg of blue charcoal powder, mix them uniformly mechanically, and then crush them with a sample making machine to make a 150-mesh uniform mixture A 1 .

[0029] ②Take 5kg of penicillin hyphae and pre-dry them at 120°C, and crush them to a powder with a particle size of 150 meshes, then use phosphoric acid at a ratio of 1:1.5 for pickling and activation, and the concentration of phosphoric acid used is 70%. The activated mycelium was heated in an oil bath at 150°C, and stirred continuously until the mycelium was matured to plasticity, and the curing time was 1 hour to obtain the mycelium pretreatment component B 1 .

[0030] ③ Dissolve 0.05kg of tapioca starch, 0.05kg of polyethylene glycol, 0.05kg of polyvinyl alcohol and 0.05kg of baking soda in 0.05kg of water and 0.05kg of ethanol to obtain the bonding component C 1 .

[0031] Mix the homogeneous material A prepared above 1 and mycelia...

Embodiment 2

[0034] ① Take 1.1kg of coking coal, 0.9kg of asphalt, 1.2kg of long-flame coal, and 1.5kg of blue charcoal powder, mix them uniformly mechanically, and then crush them with a sample making machine to make a 200-mesh uniform mixture A 2 .

[0035] ②Take 4.8kg of penicillin hyphae and dry them in advance at 120°C, and crush them into a powder with a particle size of 200 meshes, and then use phosphoric acid at a ratio of 1:1.8 for pickling and activation, where the concentration of phosphoric acid used is 80%. Heat the activated mycelia in an oil bath at 200°C, stir continuously until the mycelium is matured to plasticity, and the curing time is 2 hours, and the mycelia pretreatment component B is obtained 2 .

[0036] ③ Dissolve 0.1kg of tapioca starch, 0.1kg of polyethylene glycol, 0.1kg of polyvinyl alcohol and 0.05kg of baking soda in 0.1kg of water and 0.05kg of ethanol to obtain the bonding component C 2 .

[0037] Mix the homogeneous material A prepared above 2 and myc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com