Thermosensitive aerogel cement and preparation method thereof

An airgel and heat-sensitive technology, applied in the field of building materials, can solve problems such as lack of insulation performance, complex building details, unfavorable floor area, etc., achieve low mechanical strength, weak flexural and compressive resistance, and increase porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

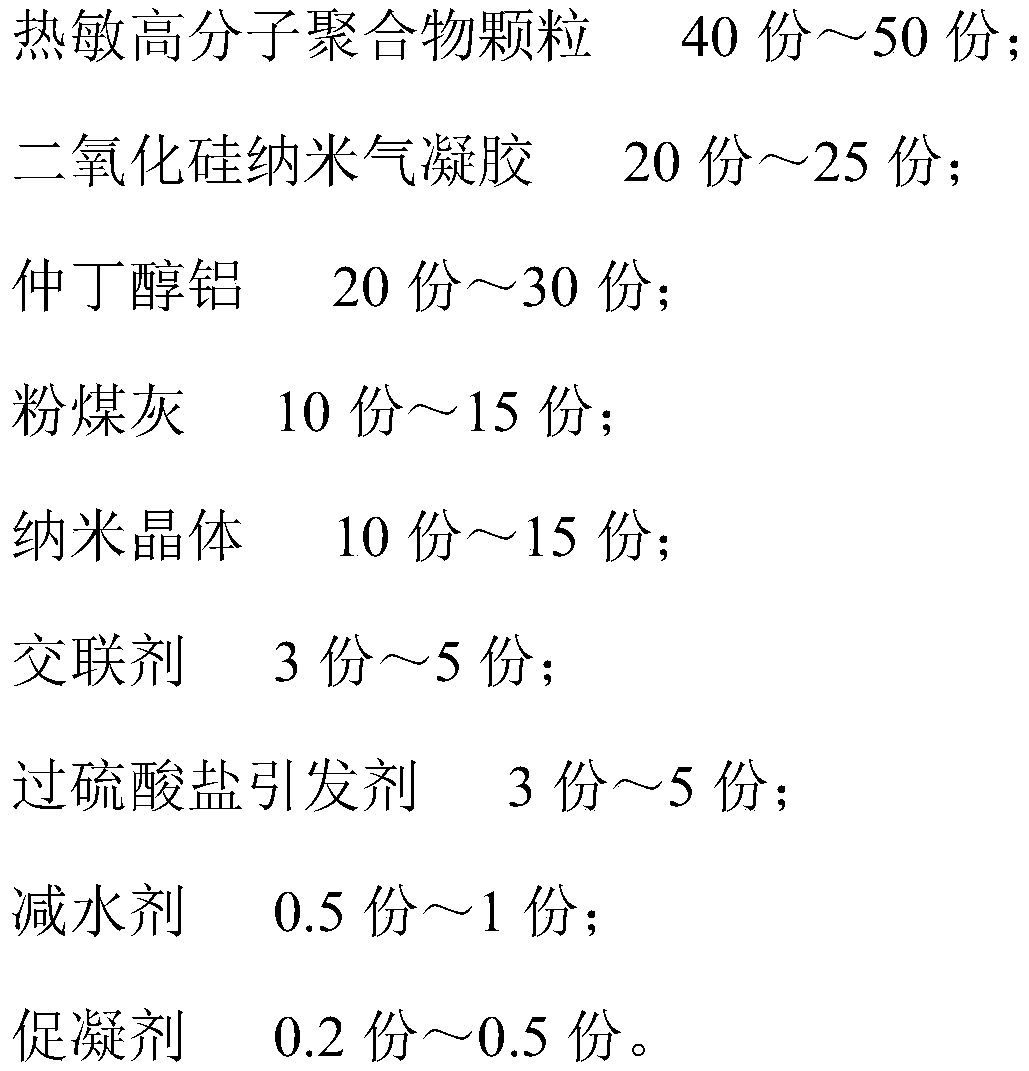

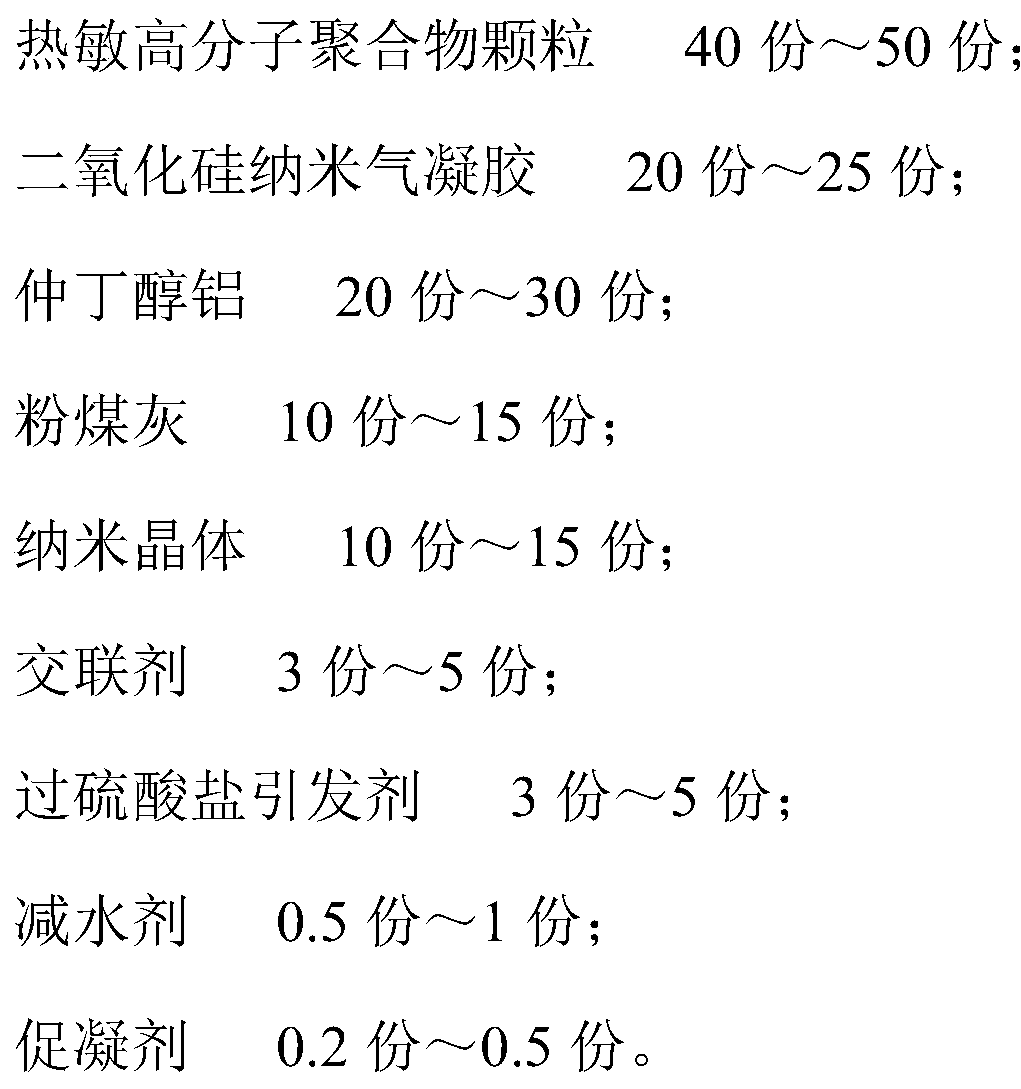

[0032] A heat-sensitive airgel cement provided in this embodiment comprises the following components in parts by weight:

[0033]

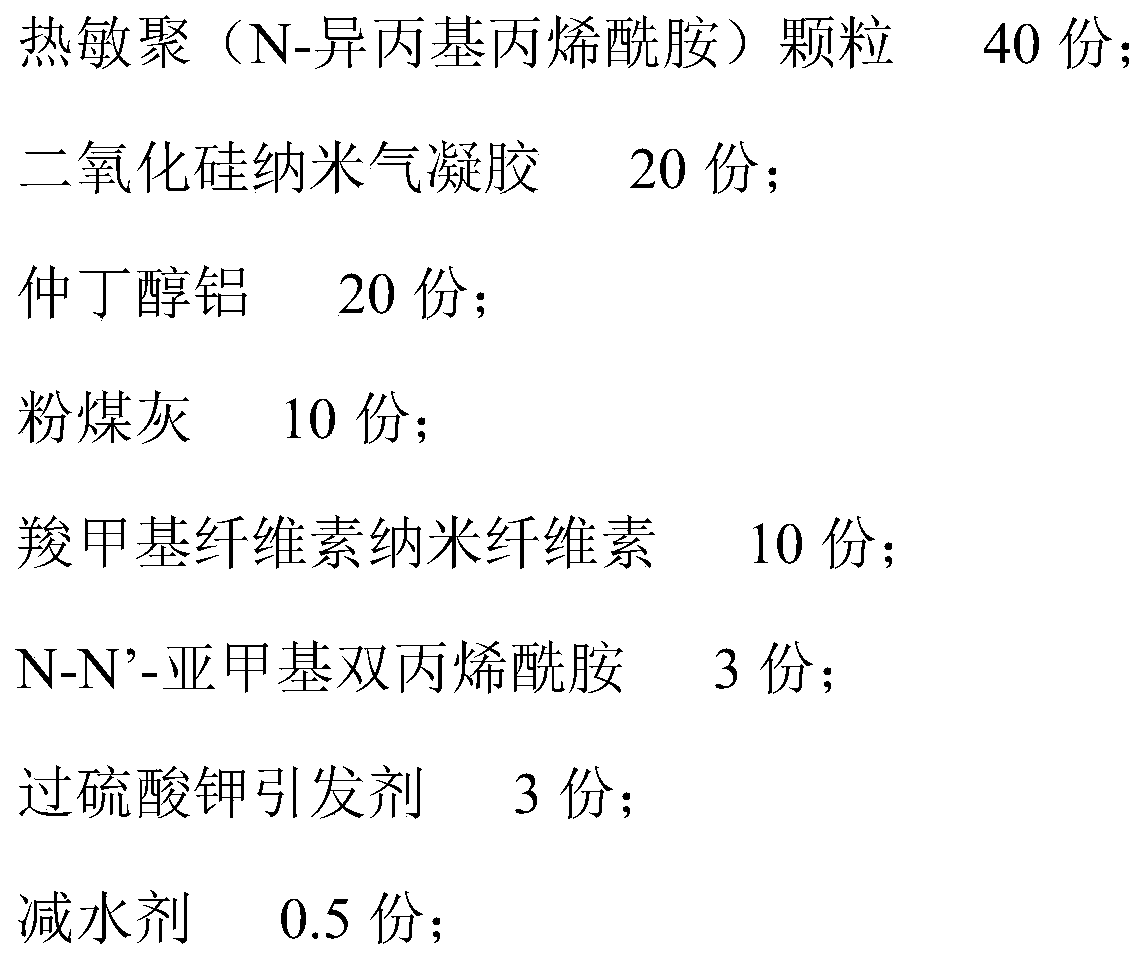

[0034]

[0035] The preparation method of the above-mentioned heat-sensitive airgel cement provided in this embodiment comprises the following steps:

[0036] 1) Mix 20 parts of aluminum sec-butoxide with distilled water so that the molar ratio of aluminum sec-butoxide to distilled water is 1:50, keep the temperature during the mixing process at 60°C to form an aluminum sec-butoxide solution, and set the concentration to 0.2 Add the nitric acid solution of M into the aluminum sec-butoxide solution, adjust the pH to 2, heat the solution to 80° C. and magnetically stir for 5 hours to form aluminum oxide nano-aqueous sol;

[0037]2) Add 10 parts of carboxymethylcellulose nanocellulose to the aluminum oxide nano-hydrosol obtained in step 1), use a freeze dryer to freeze-dry the wet glue at -60°C for 3 hours, and vacuum sublime for 3 hours to obt...

Embodiment 2

[0041] The difference between this embodiment and Example 1 is that the heat-sensitive polymer particles used are starch-grafted poly(N-isopropylacrylamide)-sodium polyacrylate, and its preparation method comprises the following steps:

[0042] 1) Weigh 3.0 g of starch and add it to 30 ml of bubble-free distilled water, and stir magnetically at 200 rpm for 10 min. During the stirring process, use a constant temperature water bath to heat and keep the temperature at 80° C. to obtain a pretreated starch solution;

[0043] 2) Add 2.0 g of acrylic acid, 4.0 g of poly(N-isopropylacrylamide) and 5 ml of 2% 4-dimethylaminopyridine to the pretreated starch solution obtained in step 1) completely neutralized by NaOH And 5ml mass fraction is 2% potassium citrate, continue to adopt water bath heating to keep temperature at 80 ℃, stir 60min with the rotating speed of 300rpm, obtain starch graft poly(N-isopropylacrylamide)-sodium polyacrylate copolymer body;

[0044] 3) The starch-grafted...

Embodiment 3

[0046] A heat-sensitive airgel cement provided in this embodiment comprises the following components in parts by weight:

[0047]

[0048] Wherein, the preparation method of starch-grafted poly-2-hydroxy ethyl acrylate-potassium polyacrylate copolymer particle comprises the following steps:

[0049] 1) Weigh 3.5g of starch and add it to 35ml of bubble-free distilled water, stir magnetically at 225rpm for 12min, heat with a constant temperature water bath to keep the temperature at 82.5°C during the stirring process, and obtain a pretreated starch solution;

[0050] 2) Add 2.5g of acrylic acid completely neutralized by KOH, 3.5g of poly 2-hydroxyethyl acrylate, 5ml of 2% 4-dimethylaminopyridine and 5ml of mass fraction into the pretreated starch solution obtained in step 1) Potassium citrate with a fraction of 2%, continued heating in a water bath to keep the temperature at 82.5°C, and stirred at a speed of 325rpm for 62min to obtain a starch-grafted poly-2-hydroxyethyl acry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com