Preparation method of novel filter stick capable of reducing release amount of crotonaldehyde in smoke

A technology of crotonaldehyde and release amount, applied in the directions of e-liquid filter, tobacco, application, etc., can solve the problems of complex filter rod preparation process, and achieve the effects of facilitating smoke transmission, increasing strength, and simple preparation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

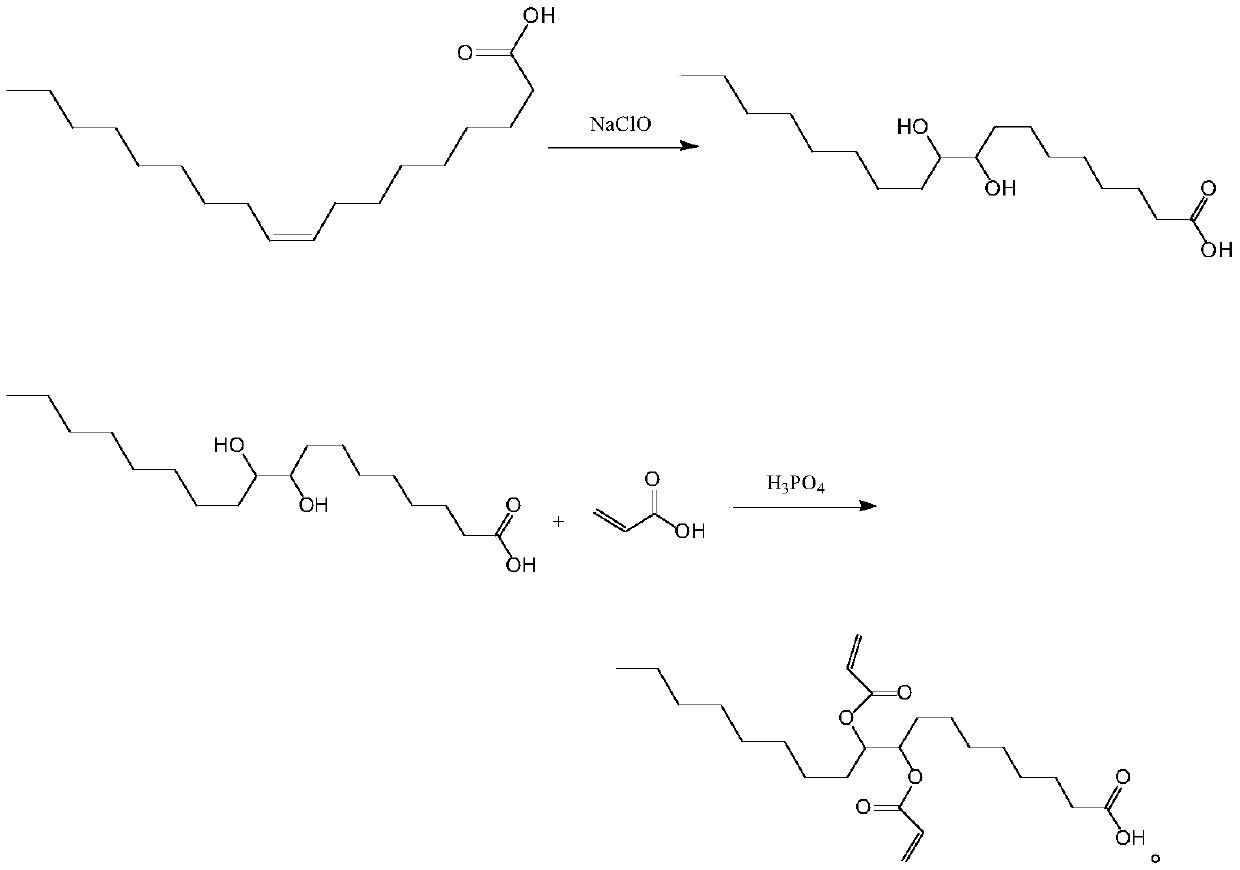

Method used

Image

Examples

Embodiment 1

[0032] The oil phase is configured first, and the composition of the oil phase is 8ml of glycidyl methacrylate, 2ml of methyl methacrylate, 0.5ml of ethylene glycol dimethacrylate, and 5g of modifier-modified silica nanoparticles.

[0033] Configure the water phase, and mix 64ml of water and 0.5g of calcium chloride evenly to prepare the water phase.

[0034] Under high-speed stirring at 500 rpm, the water phase was slowly added to the oil phase to form a high internal phase emulsion, which was poured into a filter rod forming mold with a diameter of 7.7 mm and a length of 100 mm, and sealed with nitrogen gas for 10 minutes.

[0035] In the technical solution of the present application, the forming mold of the filter rod can be changed as required, such as a filter rod mold with a diameter of 7.0mm or 6.0mm or 5.4mm and a length of 100mm or 120mm or 144mm, or other types of molds. , The model of the filter rod mold does not affect the realization of the technical solution of t...

Embodiment 2

[0038] First configure the oil phase, the composition of the oil phase is 4ml glycidyl methacrylate, 0.5ml 2-ethylhexyl acrylate, 3ml trimethylolpropane trimethacrylate, 3g modifier modified silica nano particle.

[0039] Configure the water phase, mix 60ml of water and 0.5g of sodium chloride evenly to prepare the water phase.

[0040] Under high-speed stirring at 500 rpm, the water phase was slowly added to the oil phase to form a high internal phase emulsion, which was poured into a filter rod forming mold with a diameter of 7.0 mm and a length of 120 mm, and sealed with nitrogen gas for 10 minutes. Then put the mold with high internal phase emulsion into 1.3×10 15 Q 60In the Co source, the dose rate is 36Gy / min, and the irradiation time is 36h.

[0041] The resulting solid product was placed in excess propylenediamine solution at 40°C for 24 hours, extracted with water and ethanol for 24 hours, and dried in a vacuum oven to obtain the final filter rod.

Embodiment 3

[0043] The oil phase is configured first, and the composition of the oil phase is 5ml of glycidyl methacrylate, 2ml of methyl methacrylate, 1ml of glycerol tri(αˉmethacrylate), and 4g of modifier-modified silica nanoparticles.

[0044] Configure the water phase, mix 70ml of water and 1.5g of magnesium sulfate evenly to prepare the water phase.

[0045] Under high-speed stirring at 700rpm, slowly add the water phase into the oil phase to form a high internal phase emulsion, pour it into a filter rod forming mold with a diameter of 6.0 mm and a length of 120 mm, and seal it after passing nitrogen gas for 10 minutes.

[0046] Then put the mold with high internal emulsion into 1.3×10 15 Q 60 In the Co source, the dose rate is 36Gy / min, and the irradiation time is 36h.

[0047] The resulting solid product was placed in excess ethylenediamine solution at 50°C for 24 hours, extracted with water and ethanol for 24 hours, and dried in a vacuum oven to obtain the final filter rod.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com