Lanthanum-carbon composite adsorbent doped polyvinylidene fluoride phosphorus removal film as well as preparation method and application thereof

A polyvinylidene fluoride and carbon composite technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, membranes, etc., can solve the problems of lanthanum leakage of lanthanum-carbon composite adsorbents, improve surface properties, avoid agglomeration, The effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

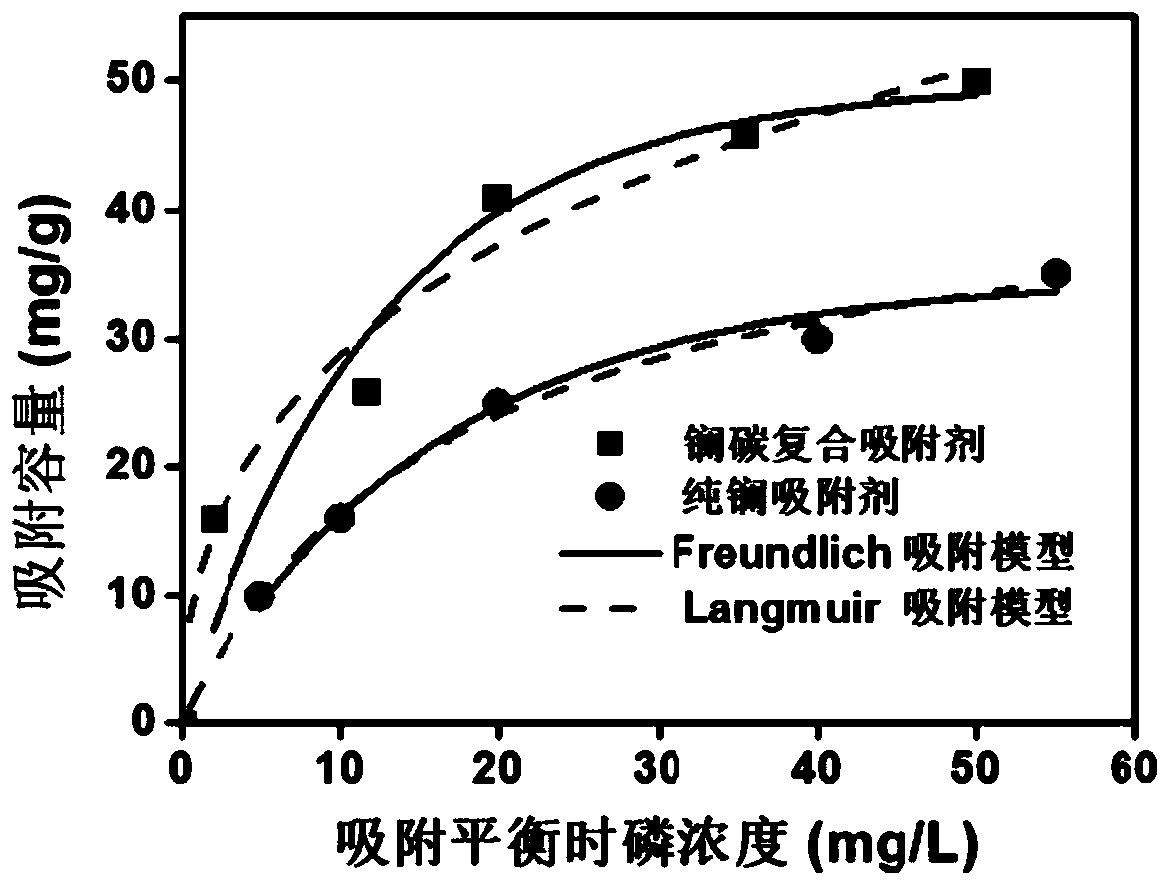

[0041]At 4°C, add 0.81g of 4,4'-diaminobiphenyl into 300mL of hydrochloric acid diluent containing 0.73% concentrated hydrochloric acid (containing 36-37wt% HCl) by volume to facilitate its dissolution. After 15 minutes, add 90 mL of 0.76% nitrous acid solution, and react for 20 minutes to completely transform the amino group into diazonium salt. At this time, the solution turns from dark yellow to bright yellow. Then add 90 mL of a mixed solution containing 0.87% tannic acid and 1.67% sodium carbonate in mass fraction. After magnetic stirring for 10 h, a tan solid product was obtained, which was filtered, and the obtained product was freeze-dried for 24 h. Grind the product after drying, then press the resulting product with LaCl 3 Mass ratio 1:38 dispersed in LaCl 3 ·6H 2 O solution, adjusted to pH = 10 with NaOH solution, filtered, dried overnight at 60°C, carbonized in a tube furnace at 700°C in an inert atmosphere for 1 hour, and the carbonized material is the lanthanu...

Embodiment 2

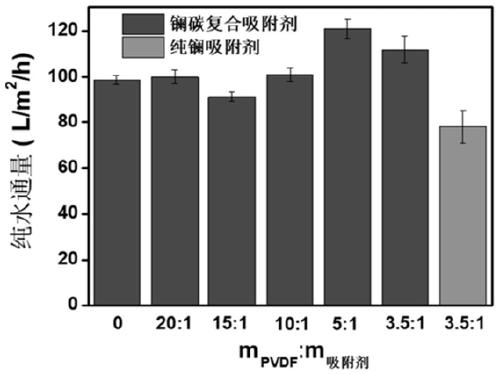

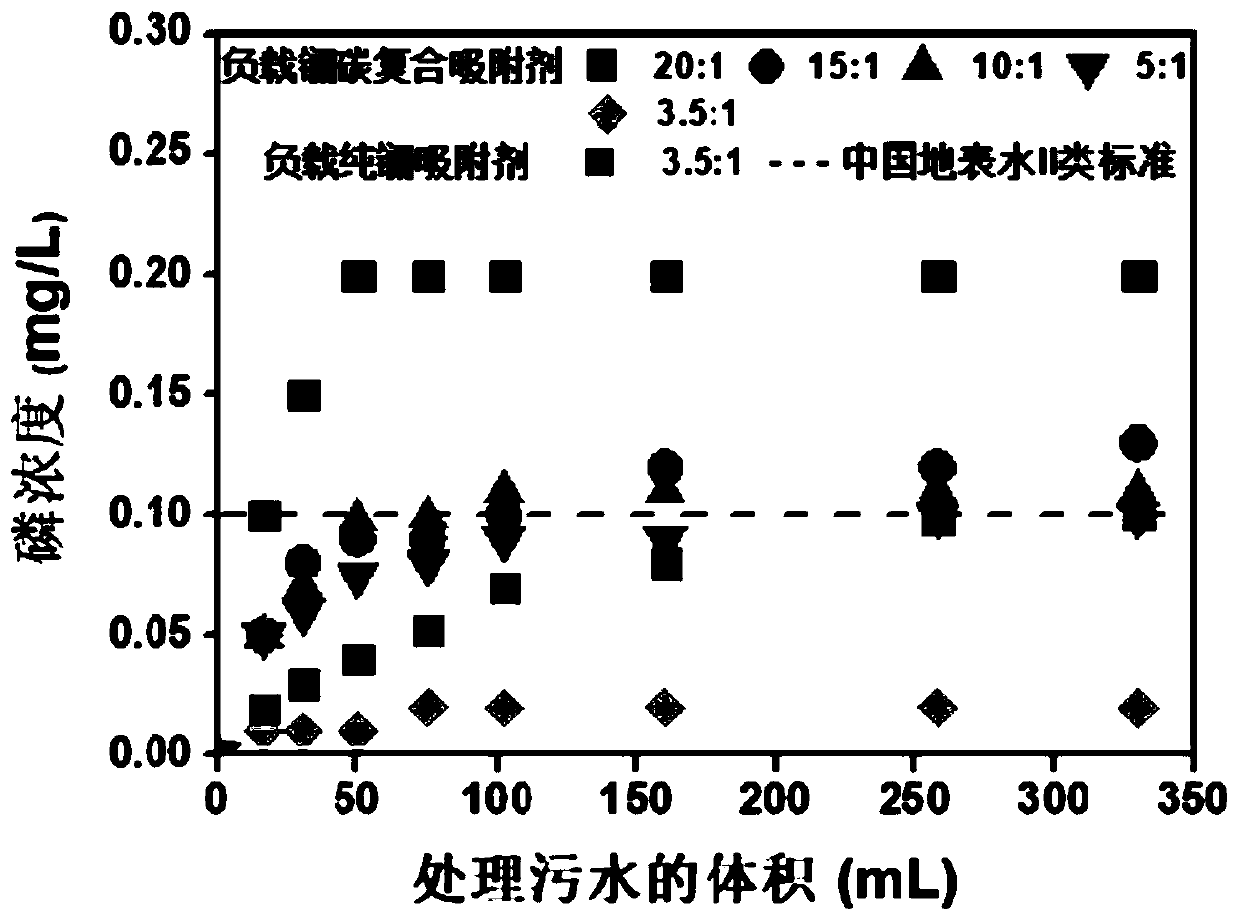

[0048] The difference from Example 1 is that 0.1875 g of the lanthanum-carbon composite adsorbent prepared in Example 1 was added to the casting solution, and the rest of the conditions were the same to obtain a polyvinylidene fluoride phosphorus removal membrane doped with the lanthanum-carbon composite adsorbent. The mass ratio of polyvinylidene fluoride to lanthanum carbon composite adsorbent is 20:1.

Embodiment 3

[0050] The difference from Example 1 is that 0.25 g of the lanthanum-carbon composite adsorbent prepared in Example 1 was added to the casting solution, and the rest of the conditions were the same to obtain a polyvinylidene fluoride phosphorus removal membrane doped with the lanthanum-carbon composite adsorbent. The mass ratio of polyvinylidene fluoride to lanthanum carbon composite adsorbent is 15:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com