Microstructure-based super-infiltration surface and preparation method thereof

A microstructure and super-wetting technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems that it is difficult to obtain array-type structures and control the surface morphology of structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. It should be understood that the embodiments described here are used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0032] Provide the substrate: choose a silicon dioxide substrate, and first use acetone, ethanol, and deionized water to ultrasonically clean it for 10 minutes, blow it dry with nitrogen, and heat it to 120° with a baking plate to keep the sample surface dry.

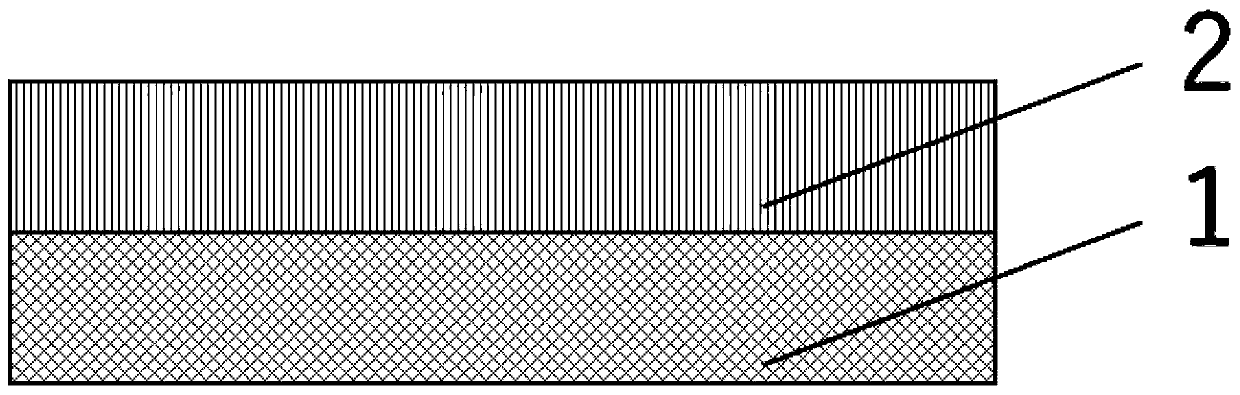

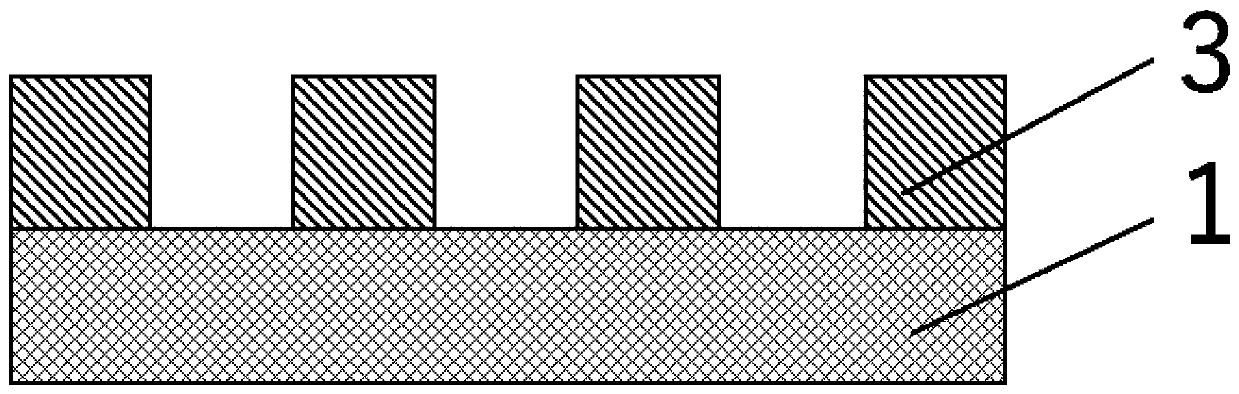

[0033] Such as figure 1 As shown, first pour SU-83035 on the substrate so that it covers one-third of the substrate, and use a coater to pre-spin and spin coat at a speed of 500r / min for 10s, and then at a speed of 3000r / min Spin coating for 60s to make SU-83035 evenly cover the substrate, put the sample on a hot plate and bake at 65°C for 10min, then bake at 95°C for 90-120min; after baking, the thickness of S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com