Modified epoxy resin composition, adhesive film and preparation method thereof

An epoxy resin glue, epoxy resin technology, applied in the field of materials, can solve the problems of not meeting the cutting-edge technology field, poor fatigue resistance, poor mechanical properties, etc., to compensate for instability, strengthen thermal shock resistance, performance boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

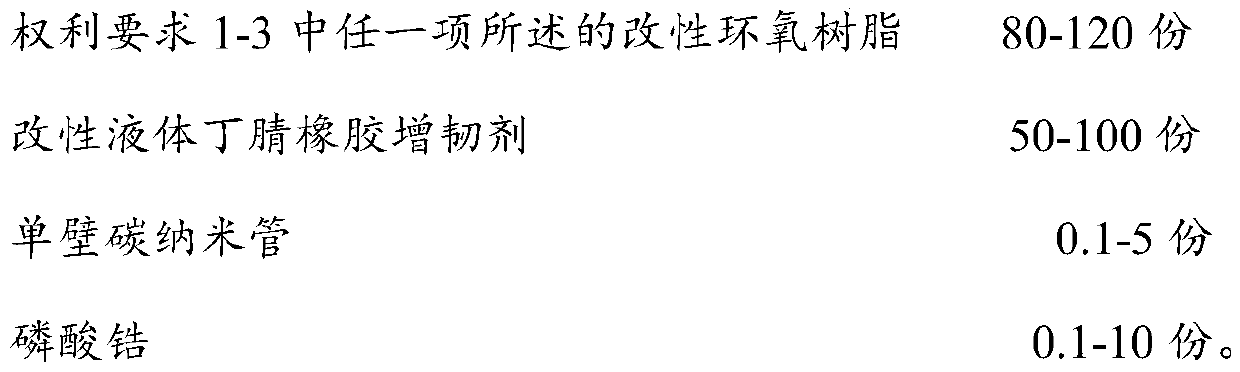

Method used

Image

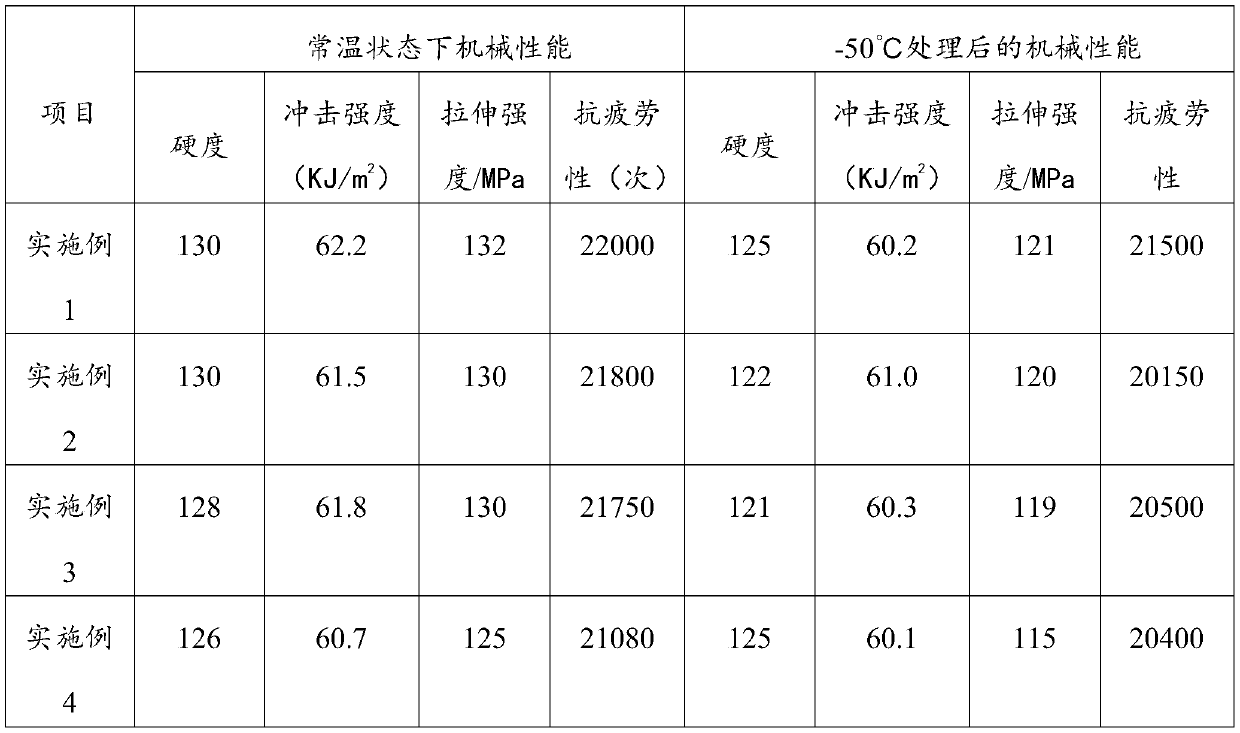

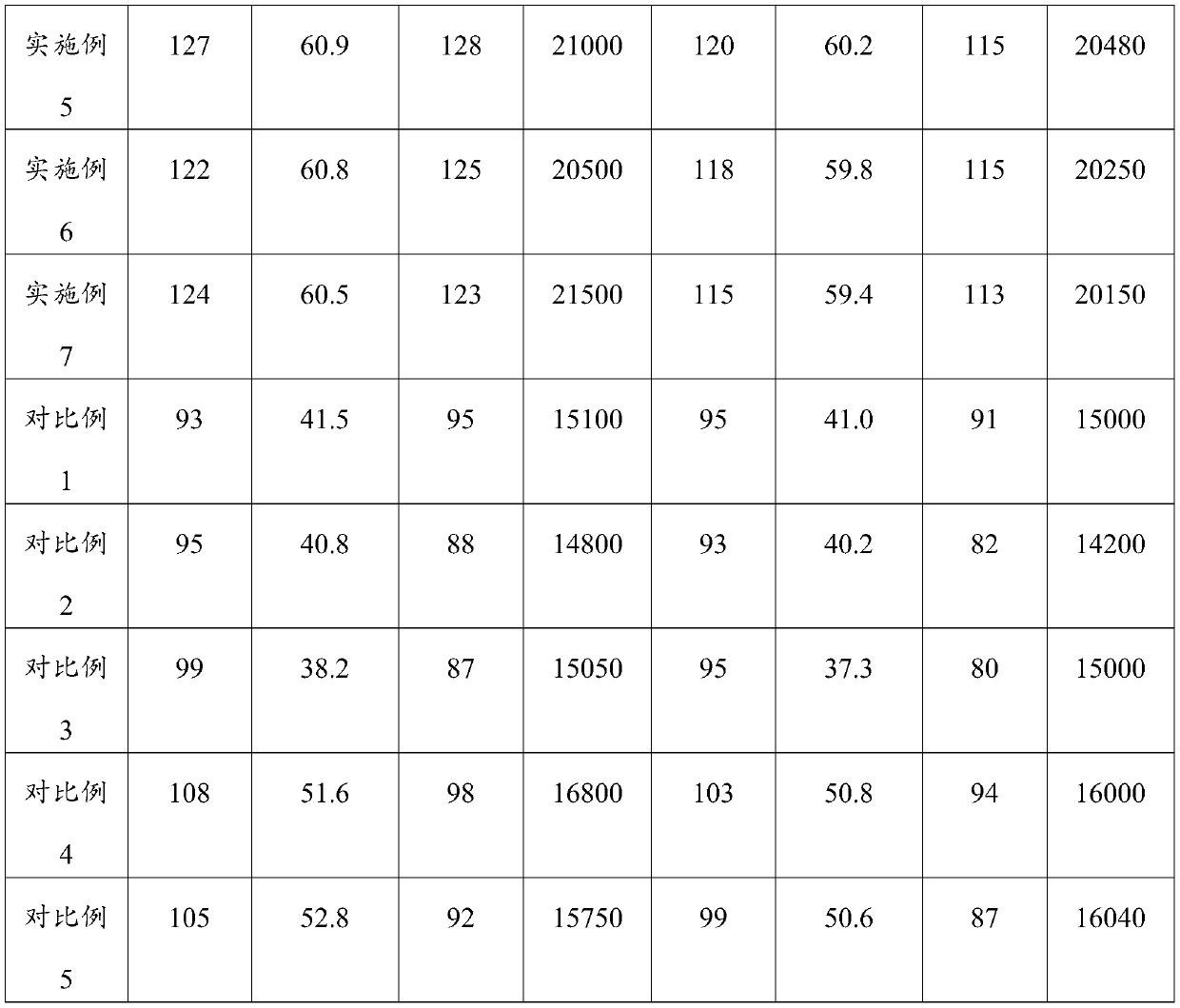

Examples

Embodiment 1

[0047](1) Preparation of silica sol: Take 30g of ethyl orthosilicate and 30g of ethanol, mix and stir, then add 25mL of deionized water, add hydrochloric acid dropwise to adjust the pH of the reaction system to 3.0, hydrolyze at 35°C for 1h, and then heat up to 50°C ℃, polymerization reaction 2h, prepared SiO2 sol. Take 35g of SiO2 sol, add 30g of trimethoxyphenylsilane and 25g of ethanol, stir, gradually dropwise add 20mL of deionized water, and dropwise add hydrochloric acid to adjust the pH of the reaction system to 3.0, react at a constant temperature of 70°C for 4h, add excess sodium carbonate, and stir Neutralize the reaction system, and when the pH of the system is greater than 7.0, filter the product and distill off water and ethanol under reduced pressure to obtain a silicone copolymer.

[0048] (2) Prepare modified epoxy resin: get 80g of bisphenol A type epoxy resin (molecular weight 4500-6500), add in acetone and dissolve completely, then add 30g acrylate oligomer ...

Embodiment 2

[0053] (1) Preparation of silica sol: Take 30g of ethyl orthosilicate and 30g of ethanol, mix and stir, then add 25mL of deionized water, add hydrochloric acid dropwise to adjust the pH of the reaction system to 3.0, hydrolyze at 35°C for 1h, and then heat up to 50°C ℃, polymerization reaction 2h, prepared SiO2 sol. Take 35g of SiO2 sol, add 30g of trimethoxyphenylsilane and 25g of ethanol, stir, gradually dropwise add 20mL of deionized water, and dropwise add hydrochloric acid to adjust the pH of the reaction system to 3.0, react at a constant temperature of 70°C for 4h, add excess sodium carbonate, and stir Neutralize the reaction system, and when the pH of the system is greater than 7.0, filter the product and distill off water and ethanol under reduced pressure to obtain a silicone copolymer.

[0054] (2) Prepare modified epoxy resin: get 80g of bisphenol A type epoxy resin (molecular weight 4500-6500), add in acetone and dissolve completely, then add 30g acrylate oligomer...

Embodiment 3

[0059] (1) Preparation of silica sol: Take 30g of ethyl orthosilicate and 30g of ethanol, mix and stir, then add 25mL of deionized water, add hydrochloric acid dropwise to adjust the pH of the reaction system to 3.0, hydrolyze at 35°C for 1h, and then heat up to 50°C ℃, polymerization reaction 2h, prepared SiO2 sol. Take 35g of SiO2 sol, add 30g of trimethoxyphenylsilane and 25g of ethanol, stir, gradually dropwise add 20mL of deionized water, and dropwise add hydrochloric acid to adjust the pH of the reaction system to 3.0, react at a constant temperature of 70°C for 4h, add excess sodium carbonate, and stir Neutralize the reaction system, and when the pH of the system is greater than 7.0, filter the product and distill off water and ethanol under reduced pressure to obtain a silicone copolymer.

[0060] (2) Prepare modified epoxy resin: get 80g of bisphenol A type epoxy resin (molecular weight 4500-6500), add in acetone and dissolve completely, then add 30g acrylate oligomer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com